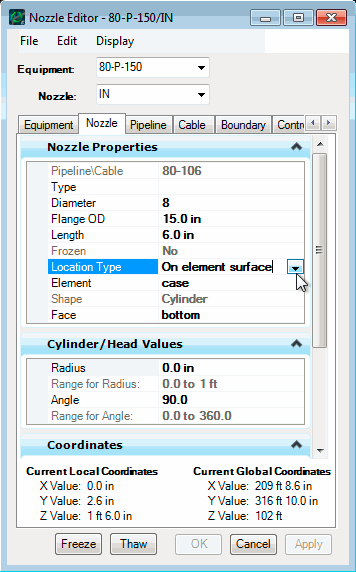

| On element surface

|

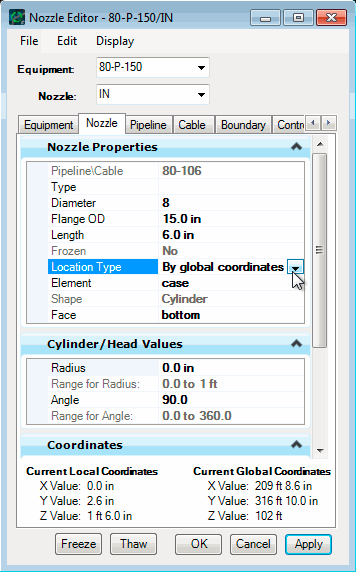

For placing of nozzles on an element surface,

you specify the element, face of the element, and placement values for the

nozzle.

Element indicates which

element of the equipment the nozzle has been placed on.

Note: Nozzles can

only be placed on elements that are box, cylinder, or elliptical head

primitives.

Face indicates which face of the

element the nozzle is on.

The next two fields depend on face type:

- For rectangular

faces, you enter the

U-Distance and the

V-Distance.

- For circular faces,

you enter the

Radius and

Angle.

- For body faces of

cylinders, you enter

Distance and

Angle.

From the

Orientation Vector fields, you can change

the direction the nozzle points to. You are reminded that the

Z Component vector is the outward normal

to the surface of the face the nozzle is placed on.

The

Current Global Coordinates lists the

location of the nozzle (center of nozzle) with respect to the project’s global

coordinates. This section of the dialog does not change with Location Type.

|

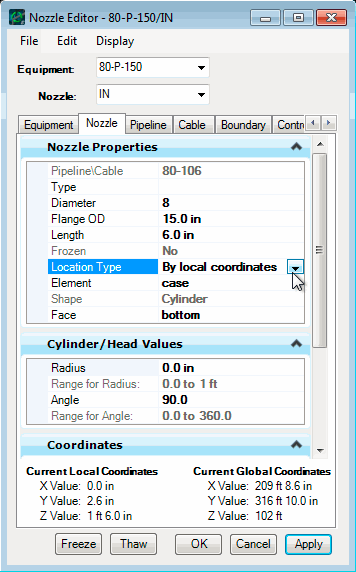

| By local coordinates

|

Local coordinates allow you to

place nozzles in x, y, and z with the placement point of the equipment instance

acting as the origin of the coordinate system. Changing the Orientation vector

of the nozzle is done with respect to the orientation of the equipment.

By local

coordinates

|

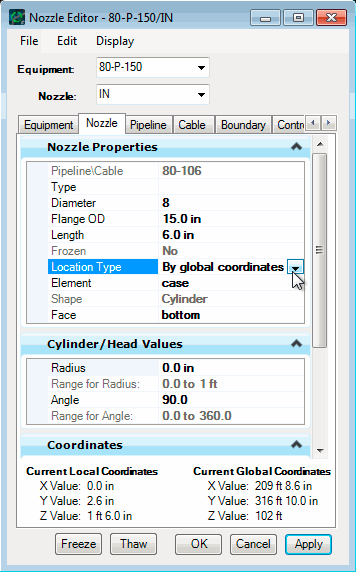

| By global coordinates

|

Global coordinates allow you to

place nozzles in absolute x, y, and z. The Orientation vector of the nozzle is

with respect to the global axes of the project.

By global

coordinates

|