V. Element Offset Table Top Comparison

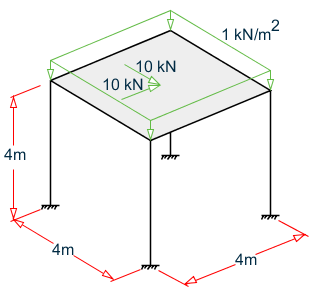

A simple table-like structure is composed of four column members and a single plate element. Verify that the element offset command gives similar results as those from other modeling methods.

Problem

The plate element is subjected to a pressure load acting vertically downward along global Y direction of 1 kN/m2. Also, two concentrated point loads of 10 kN are acting laterally along global X & global Z directions at center of the plate element.

- Slab thickness = 20 cm

- Columns and beams = 40 cm square

- Concrete materials for all members and elements*

Offset the slab edge by 1/2 the column width (20 cm) in the plan dimensions and 1/2 the slab depth (10 cm) into the thickness of the slab.

Calculations

The model is generated with three different approaches to include the offset effect on the plate. First approach is to use ELEMENT OFFSET command wherein offset distances are directly assigned to corner joints of the plate without any need to manually compute co-ordinates for offset joints.

The second approach is to use control-dependent specification instead of offset commands with rigid connections between offset joints of the plate & beam-column junction for load transfer. The third approach is to use short, relatively stiff beam members (*assigned with material STIFF having high E & G values) instead of control-dependent specification so that offset joints of plate and beam-column junction are rigidly connected to ensure load transfer.

- Using element offsets in the global direction (nodes 101, 102, 103, etc.)

- Using rigid links with a high stiffness value (nodes 201, 202, 203, etc.)

- Using a control / dependent specification (nodes 301, 302, 303, etc.)

Additional node numbers added for different approaches

Comparison

Results for the model created with element offset command should be identical with the model created with control-dependent approach or short rigid beam approach. Hence, the results from control-dependent and short rigid beam models are treated as reference values against which results from model with element offset command are compared.

| Result Type | Modeling Method | Difference | |||

|---|---|---|---|---|---|

| Element Offsets | Rigid Links | Control / Dependent | |||

| Joint deflection (cm) | Joint 2, X | 0.0372 | 0.0372 | 0.0372 | none |

| Joint 2, Y | 0.0002 | 0.0002 | 0.0002 | none | |

| Joint 2, Z | 0.0372 | 0.0372 | 0.0375 | none | |

| Joint 7, X | 0.0373 | 0.0373 | 0.0373 | none | |

| Joint 7, Y | -0.0009 | -0.0009 | -0.0009 | none | |

| Joint 7, Z | 0.0373 | 0.0373 | 0.0373 | none | |

| Support Reactions | Joint 8, FX (kN) | -2.82 | -2.82 | -2.82 | none |

| Joint 8, FY (kN) | 8.05 | 8.05 | 8.05 | none | |

| Joint 8, FZ (kN) | -2.82 | -2.82 | -2.82 | none | |

| Joint 8, MX (kN·m) | -5.87 | -5.87 | -5.87 | none | |

| Joint 8, MZ | 5.87 | 5.87 | 5.87 | none | |

STAAD Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\04 Plates Shells\Element Offset Table Top Comparison.STD is typically installed with the program.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 16-DEC-20

END JOB INFORMATION

INPUT WIDTH 79

UNIT METER KN

JOINT COORDINATES

101 0 0 0; 102 0 4 0; 103 4 4 0; 104 4 0 0; 105 0 0 4; 106 0 4 4; 107 4 4 4;

108 4 0 4; 201 0 0 10; 202 0 4 10; 203 4 4 10; 204 4 0 10; 205 0 0 14;

206 0 4 14; 207 4 4 14; 208 4 0 14; 209 0.2 4.1 10.2; 210 3.8 4.1 10.2;

211 0.2 4.1 13.8; 212 3.8 4.1 13.8; 301 0 0 20; 302 0 4 20; 303 4 4 20;

304 4 0 20; 305 0 0 24; 306 0 4 24; 307 4 4 24; 308 4 0 24; 309 0.2 4.1 20.2;

310 3.8 4.1 20.2; 311 0.2 4.1 23.8; 312 3.8 4.1 23.8;

*Coordinates for Structure 1: Using ELEMENT OFFSETS

*Coordinates for structure 2: Using rigid, linking members

*Coordinates for structure 3: Using master/slave links

MEMBER INCIDENCES

101 101 102; 102 103 104; 103 105 106; 104 107 108; 105 102 103; 106 103 107;

107 107 106; 108 106 102; 201 201 202; 202 203 204; 203 205 206; 204 207 208;

205 202 203; 206 203 207; 207 207 206; 208 206 202; 210 202 209; 211 203 210;

212 207 212; 213 206 211; 301 301 302; 302 303 304; 303 305 306; 304 307 308;

305 302 303; 306 303 307; 307 307 306; 308 306 302;

*Structure 1

*Structure 2

*Structure 3

* 310 302 309; 311 303 310; 312 307 312; 313 306 311;

ELEMENT INCIDENCES SHELL

109 102 103 107 106; 209 209 210 212 211; 309 309 310 312 311;

*Structure 1

*Structure 2

*Structure 3

ELEMENT PROPERTY

109 209 309 THICKNESS 0.2

DEFINE MATERIAL START

ISOTROPIC CONCRETE

E 2.17185e+07

POISSON 0.17

DENSITY 23.5616

ALPHA 1e-05

DAMP 0.05

G 9.28139e+06

TYPE CONCRETE

STRENGTH FCU 27579

ISOTROPIC STIFF

E 1e+14

POISSON 0.17

DENSITY 0.0001

G 5e+13

END DEFINE MATERIAL

MEMBER PROPERTY

101 TO 108 PRIS YD 0.4 ZD 0.4

201 TO 208 PRIS YD 0.4 ZD 0.4

210 TO 213 PRIS YD 0.4 ZD 0.4

301 TO 308 PRIS YD 0.4 ZD 0.4

CONSTANTS

MATERIAL CONCRETE MEMB 101 TO 109 201 TO 209 301 TO 309

*A material with very high E and G is used for rigid links structure 2

MATERIAL STIFF MEMB 210 TO 213

ELEMENT OFFSET

***Global Offsets for structure 1

109 JT1 0.2 0.1 0.2

109 JT2 -0.2 0.1 0.2

109 JT3 -0.2 0.1 -0.2

109 JT4 0.2 0.1 -0.2

***Local Offset: an alternate method of specifying the same resulting offset

*9 JT1 LOCAL 0.2 0.2 -0.1

*9 JT2 LOCAL -0.2 0.2 -0.1

*9 JT3 LOCAL -0.2 -0.2 -0.1

*9 JT4 LOCAL 0.2 -0.2 -0.1

SUPPORTS

101 104 105 108 FIXED

201 204 205 208 FIXED

301 304 305 308 FIXED

* Master / slave specification for structure 3

DEPENDENT RIGID CONTROL 302 JOINT 309

DEPENDENT RIGID CONTROL 303 JOINT 310

DEPENDENT RIGID CONTROL 306 JOINT 311

DEPENDENT RIGID CONTROL 307 JOINT 312

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

* The elements in each of the models is loaded identically

ELEMENT LOAD

109 209 309 PR GY -1

109 209 309 PR GX 10 0 0

109 209 309 PR GZ 10 0 0

PERFORM ANALYSIS PRINT ALL

PRINT ANALYSIS RESULTS

PRINT ELEMENT JOINT STRESSES

PRINT ELEMENT FORCE

FINISH

STAAD Output

JOINT DISPLACEMENT (CM RADIANS) STRUCTURE TYPE = SPACE ------------------ JOINT LOAD X-TRANS Y-TRANS Z-TRANS X-ROTAN Y-ROTAN Z-ROTAN 101 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 102 1 0.0372 0.0002 0.0372 0.0000 0.0000 -0.0000 103 1 0.0372 -0.0004 0.0371 0.0001 -0.0000 -0.0000 104 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 105 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 106 1 0.0371 -0.0004 0.0372 0.0000 0.0000 -0.0001 107 1 0.0373 -0.0009 0.0373 0.0000 0.0000 -0.0000 108 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 201 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 202 1 0.0372 0.0002 0.0372 0.0000 0.0000 -0.0000 203 1 0.0372 -0.0004 0.0371 0.0001 -0.0000 -0.0000 204 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 205 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 206 1 0.0371 -0.0004 0.0372 0.0000 0.0000 -0.0001 207 1 0.0373 -0.0009 0.0373 0.0000 0.0000 -0.0000 208 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 209 1 0.0375 -0.0011 0.0375 0.0000 0.0000 -0.0000 210 1 0.0376 -0.0006 0.0376 0.0001 -0.0000 -0.0000 211 1 0.0376 -0.0006 0.0376 0.0000 0.0000 -0.0001 212 1 0.0375 -0.0001 0.0375 0.0000 0.0000 -0.0000 301 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 302 1 0.0372 0.0002 0.0372 0.0000 0.0000 -0.0000 303 1 0.0372 -0.0004 0.0371 0.0001 -0.0000 -0.0000 304 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 305 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 306 1 0.0371 -0.0004 0.0372 0.0000 0.0000 -0.0001 307 1 0.0373 -0.0009 0.0373 0.0000 0.0000 -0.0000 308 1 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 309 1 0.0375 -0.0011 0.0375 0.0000 0.0000 -0.0000 310 1 0.0376 -0.0006 0.0376 0.0001 -0.0000 -0.0000 311 1 0.0376 -0.0006 0.0376 0.0000 0.0000 -0.0001 312 1 0.0375 -0.0001 0.0375 0.0000 0.0000 -0.0000 STAAD SPACE -- PAGE NO. 8 SUPPORT REACTIONS -UNIT KN METE STRUCTURE TYPE = SPACE ----------------- JOINT LOAD FORCE-X FORCE-Y FORCE-Z MOM-X MOM-Y MOM Z 101 1 -2.60 -1.57 -2.60 -5.57 0.00 5.57 104 1 -2.40 3.24 -2.18 -5.01 0.00 5.31 105 1 -2.18 3.24 -2.40 -5.31 -0.00 5.01 108 1 -2.82 8.05 -2.82 -5.87 0.00 5.87 201 1 -2.60 -1.57 -2.60 -5.57 0.00 5.57 204 1 -2.40 3.24 -2.18 -5.01 0.00 5.31 205 1 -2.18 3.24 -2.40 -5.31 -0.00 5.01 208 1 -2.82 8.05 -2.82 -5.87 0.00 5.87 301 1 -2.60 -1.57 -2.60 -5.57 0.00 5.57 304 1 -2.40 3.24 -2.18 -5.01 0.00 5.31 305 1 -2.18 3.24 -2.40 -5.31 -0.00 5.01 308 1 -2.82 8.05 -2.82 -5.87 0.00 5.87