V. AISC 360-16 Tapered Tube Section

Verify the axial compression capacity, flexure capacity, and interaction ratio of a tapered tube section member per both the LRFD and ASD methods of the AISC 360-16 code.

Details

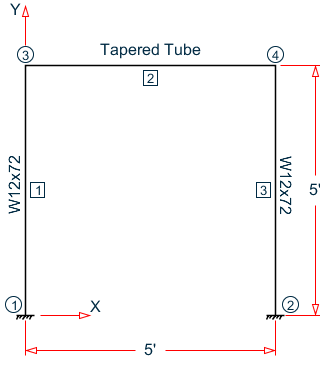

A 5' × 5' portal frame consists of W12x72 columns and a steel tapered member for the beam.

- E = 29,000 ksi

- Fy = 50 ksi

Validation

Design Forces

- Mz = 505.66 in·kips

- Fy = 67.2 kips

- Fx = 10.23 kips

Section Properties

The section at the right end (OD = 10 in.) has the following properties:

- Inner diameter, ID = 9 in.

- Area, Ag = (π/4)(OD2 - ID2) = 14.92 in2

- Form factor = 0.49 + 0.8 (t / OD) = 0.53

- Shear area, Ay = 14.92(0.53) = 7.909 in2

- Moment of inertia,

- Elastic section modulus,

- Radius of gyration,

- Plastic section modulus,

- HSS Torsional constant,

Section Classification

Flange in compression

Per Table B4.1a, Case 9, , therefore flanges are non-slender for compression. The web is similarly non-slender for compression.

Flange in bending (use half the longer flange width as the outstanding width):

Per Table B4.1b, Case20, , therefore flange is compact for bending.

Compression Capacity

| (Eq. E3-4) |

| (Eq. E3-2) |

| Pn = Ag× Fcr = 14.92 × 48.85 = 729.0 kips | (Eq. E3-1) |

- The ultimate compression capacity (LRFD) = ϕcPn = 0.9 × 729.0 = 656.1 kips

- The allowable compression capacity (ASD) = Pn/Ωc = 729.0 / 1.67 = 436.5 kips

Shear Capacity

The distance from the maximum shear force (ends) to zero shear force (mid-span), Lv = L / 2 = 30 in.

The critical shear stress, Fcr, is the minimum of:

Fcr = 30 ksi

Nominal shear capacity:

The shear capacity:- The ultimate shear capacity (LRFD) = ϕcVn = 0.9 × 223.8 = 201.5 kips

- The allowable shear capacity (ASD) = Vn/Ωc = 223.8 / 1.67 = 134.0 kips

Calculate Bending Capacity

Bending capacity in plastic yielding:

Mp = Fy × Z = 50 × 45.17 = 2,259 in·kips < 1.6Fy × S = 1.6 (50) (33.76) = 2,701 in·kips

- The ultimate bending capacity (LRFD) = ϕbMy = 0.9 × 2,259 = 2,033 in·kips

- The allowable bending capacity (ASD) = My/Ωb = 2,259 / 1.67 = 1,352 in·kips

Torsional Capacity

The critical stress, Fcr, is the larger of:

But shall not exceed:

Fcr = 30 ksi

Nominal torsional capacity:

The torsional capacity:- The ultimate torsional capacity (LRFD) = ϕcTn = 0.9 × 2,126 = 1,914 kips

- The allowable torsional capacity (ASD) = Tn/Ωc = 2,126 / 1.67 = 1,273 kips

Interaction Ratio for Bending and Compression

Check the interaction ratio for Load Case 1:

So use Eq. H1-1b for both methods: .

Results

| Result Type | Reference | STAAD.Pro | Difference | Comments | |

|---|---|---|---|---|---|

| LRFD | Compression capacity (kips) | 656.1 | 656.1 | none | |

| Shear capacity (kips) | 201.5 | 201.5 | none | ||

| Bending capacity (in·kips) | 2,033 | 2,033 | none | ||

| Torsional capacity (in·kips) | 1,914 | 1,914 | none | ||

| Interaction ratio | 0.257 | 0.257 | none | ||

| ASD | Compression capacity (kips) | 436.5 | 436.5 | none | |

| Shear capacity (kips) | 134.0 | 134 | none | ||

| Bending capacity (in·kips) | 1,352 | 1,352 | none | ||

| Torsional capacity (in·kips) | 1,273 | 1,273 | none | ||

| Interaction ratio | 0.386 | 0.386 | none | ||

STAAD.Pro Input

The following design parameters are used:

The remaining parameters all use their default values.

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\09 Steel Design\US\AISC\AISC 360-16 Tapered Tube Section.STD is typically installed with the program.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 13-Apr-21

END JOB INFORMATION

INPUT WIDTH 79

UNIT INCHES KIP

JOINT COORDINATES

1 0 0 0; 2 0 60 0; 3 60 60 0; 4 60 0 0;

MEMBER INCIDENCES

1 1 2; 2 2 3; 3 3 4;

DEFINE MATERIAL START

ISOTROPIC STEEL

E 29000

POISSON 0.3

DENSITY 0.000283

ALPHA 6.5e-06

DAMP 0.03

G 11200

TYPE STEEL

STRENGTH RY 1.5 RT 1.2

END DEFINE MATERIAL

MEMBER PROPERTY AMERICAN

1 TABLE ST W12X72

3 TABLE ST W12X72

MEMBER PROPERTY

2 PRIS ROUND STA 12 END 10 THI 0.5

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 FIXED

4 FIXED

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

MEMBER LOAD

2 UNI GY -2.25

LOAD 2 LOADTYPE None TITLE LOAD CASE 2

JOINT LOAD

2 FX 50 FZ 25

LOAD 3 LOADTYPE None TITLE LOAD CASE 3

MEMBER LOAD

2 CMOM GX 0.75

PERFORM ANALYSIS

PRINT ANALYSIS RESULTS

PARAMETER 1

CODE AISC UNIFIED 2016

SLF 0.8 MEMB 2

FYLD 50 ALL

FU 60 ALL

METHOD LRFD

STP 2 MEMB 2

TRACK 2 MEMB 2

CHECK CODE MEMB 2

PARAMETER 2

CODE AISC UNIFIED 2016

SLF 0.8 MEMB 2

FYLD 50 ALL

FU 60 ALL

METHOD ASD

STP 2 MEMB 2

TRACK 2 MEMB 2

CHECK CODE MEMB 2

FINISH

STAAD.Pro Output

STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 |-----------------------------------------------------------------------------| | Member No: 2 Profile: PRISMAT (AISC SECTIONS)| | Status: PASS Ratio: 0.334 Loadcase: 1 | | Location: 60.00 Ref: Cl.G1 | | Pz: 10.23 C Vy: -67.19 Vx: 0.000 | | Tz: 0.000 My: 0.000 Mx: 505.7 | |-----------------------------------------------------------------------------| | COMPRESSION SLENDERNESS | | Actual Slenderness Ratio : 17.839 | | Allowable Slenderness Ratio : 200.000 LOC : 60.00 | |-----------------------------------------------------------------------------| | STRENGTH CHECKS | | Critical L/C : 1 Ratio : 0.334(PASS) | | Loc : 60.00 Condition : Cl.G1 | |-----------------------------------------------------------------------------| | SECTION PROPERTIES (LOC: 60.00, PROPERTIES UNIT: IN ) | | Ag : 1.492E+01 Axx : 7.909E+00 Ayy : 7.909E+00 | | Ixx : 1.688E+02 Iyy : 1.688E+02 J : 3.376E+02 | | Sxx+: 3.376E+01 Sxx-: 3.376E+01 Zxx : 4.517E+01 | | Syy+: 3.376E+01 Syy-: 3.376E+01 Zyy : 4.517E+01 | | Cw : 0.000E+00 x0 : 0.000E+00 y0 : 0.000E+00 | |-----------------------------------------------------------------------------| | MATERIAL PROPERTIES | | Fyld: 50.000 Fu: 60.000 | |-----------------------------------------------------------------------------| | Actual Member Length: 60.000 | | Design Parameters (Built-Up) | | Kx: 1.00 Ky: 1.00 NSF: 1.00 SLF: 0.80 CSP: 12.00 | |-----------------------------------------------------------------------------| | COMPRESSION CLASSIFICATION (L/C: 2 LOC: 60.00) | | λ λp λr CASE | | Flange: NonSlender 20.00 N/A 63.80 Table.B4.1a.Case9 | | Web : NonSlender 20.00 N/A 63.80 Table.B4.1a.Case9 | | | | FLEXURE CLASSIFICATION (L/C: 2 LOC: 60.00) | | λ λp λr CASE | | Flange: Compact 20.00 40.60 179.80 Table.B4.1b.Case20 | | Web : Compact 20.00 40.60 179.80 Table.B4.1b.Case20 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 8 STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL TENSION | |-----------------------------------------------------------------------------| | TENSILE YIELDING | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.000 671.5 0.000 Cl.D2 1 60.00 | | | | Intermediate Results : | | Nom. Ten. Yld Cap : Pn = 746.13 kip Eq.D2-1 | |-----------------------------------------------------------------------------| | TENSILE RUPTURE | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.000 537.2 0.000 Cl.D2 1 60.00 | | | | Intermediate Results : | | Effective area : Ae = 11.938 in2 Eq.D3-1 | | Nom. Ten. Rpt Cap : Pn = 716.28 kip Eq.D2-2 | |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL COMPRESSION | |-----------------------------------------------------------------------------| | FLEXURAL BUCKLING X | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 23.86 656.1 0.036 Cl.E3 2 60.00 | | | | Intermediate Results : | | Effective Slenderness : Lcx/rx = 17.839 Cl.E2 | | Elastic Buckling Stress : Fex = 899.40 ksi Eq.E3-4 | | Crit. Buckling Stress : Fcrx = 48.850 ksi Eq.E3-2 | | Nom. Flexural Buckling : Pnx = 728.97 kip Eq.E3-1 | |-----------------------------------------------------------------------------| | FLEXURAL BUCKLING Y | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 23.86 656.1 0.036 Cl.E3 2 60.00 | | | | Intermediate Results : | | Effective Slenderness : Lcy/ry = 17.839 Cl.E2 | | Elastic Buckling Stress : Fey = 899.40 ksi Eq.E3-4 | | Crit. Buckling Stress : Fcry = 48.850 ksi Eq.E3-2 | | Nom. Flexural Buckling : Pny = 728.97 kip Eq.E3-1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 9 STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR SHEAR | |-----------------------------------------------------------------------------| | SHEAR ALONG X | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.5390E-01 201.5 0.000 Cl.G1 2 60.00 | | | | Intermediate Results : | | Nom. Shear Along X : Vnx = 223.84 kip Eq.G5-1 | | Crit. Stress Fcr Along X : Fcrx = 30.000 ksi Eq.G5-2 | |-----------------------------------------------------------------------------| | SHEAR ALONG Y | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 67.19 201.5 0.334 Cl.G1 1 60.00 | | | | Intermediate Results : | | Nom. Shear Along Y : Vny = 223.84 kip Eq.G5-1 | | Crit. Stress Fcr Along Y : Fcrx = 30.000 ksi Eq.G5-2 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 10 STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR BENDING | |-----------------------------------------------------------------------------| | FLEXURAL YIELDING (X) | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 505.7 2033. 0.249 Cl.F8.1 1 60.00 | | | | Intermediate Results : | | Nom Flex Yielding Along X : Mnx = 2258.3 kip-in Eq.F8-1 | |-----------------------------------------------------------------------------| | FLEXURAL YIELDING (Y) | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | -1.617 2033. 0.001 Cl.F8.1 2 60.00 | | | | Intermediate Results : | | Nom Flex Yielding Along Y : Mny = 2258.3 kip-in Eq.F8-1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 11 STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL BEND INTERACTION | |-----------------------------------------------------------------------------| | COMBINED FORCES CLAUSE H1 | | RATIO CRITERIA L/C LOC | | 0.257 Eq.H1-1b 1 60.00 | | | | Intermediate Results : | | Axial Capacity : Pc = 656.07 kip Cl.H1.1 | | Moment Capacity : Mcx = 2032.5 kip-in Cl.H1.1 | | Moment Capacity : Mcy = 2032.5 kip-in Cl.H1.1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 12 STAAD.PRO CODE CHECKING - AISC 360-16 LRFD (V1.2) ***************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR TORSION | |-----------------------------------------------------------------------------| | TORSION CAPACITY | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 238.5 1914. 0.125 Cl.H3.1 2 60.00 | | | | Intermediate Results : | | Crit. Stress. Fcr : Fcr = 30.000 ksi Cl.H3.1(a) | | Nom. Strength : Tn = 2126.5 kip-in Eq.H3-1 | |-----------------------------------------------------------------------------| ***NOTE : AISC 360-16 Design Statement for STAAD.Pro. *** AXIS CONVENTION ***: ======================== The capacity results and intermediate results in the report follow the notations and axes labels as defined in the AISC 360-16 code. The analysis results are reported in STAAD.Pro axis convention and the AISC 360:16 design results are reported in AISC 360-16 code axis convention. AISC Spec. STAAD.Pro Description ------------ ----------- ------------- X Z Axis typically parallel to the sections principal major axis. Y Y Axis typically parallel to the sections principal minor axis. Z X Longitudinal axis perpendicular to the cross section. SECTION FORCES AXIS MAPPING: - AISC Spec. STAAD.Pro Description ------------ ----------- ------------- Pz FX Axial force. Vy FY Shear force along minor axis. Vx FZ Shear force along major axis. Tz MX Torsional moment. My MY Bending moment about minor axis. Mx MZ Bending moment about major axis. *** DESIGN MESSAGES ***: ======================= 1. Section classification reported is for the cross section and loadcase that produced the worst case design ratio for flexure/compression Capacity results. 2. Results for any Capacity/Check that is not relevant for a section/loadcase based on the code clause in AISC 360-16 will not be shown in the report. 3. Bending results are reported as being �about� the relevant axis (X/Y), while the results for shear are reported as being for shear forces �along� the axis. E.g : Mx indicates bending about the X axis, while Vx indicates shear along the X axis. *** ABBREVIATIONS ***: ====================== F-T-B = Flexural-Torsional Buckling L-T-B = Lateral-Torsional Buckling F-L-B = Flange Local Buckling W-L-B = Web Local Buckling L-L-B = Leg Local Buckling C-F-Y = Compression Flange Yielding T-F-Y = Tension Flange Yielding 52. PARAMETER 2 53. CODE AISC UNIFIED 2016 54. SLF 0.8 MEMB 2 55. FYLD 50 ALL 56. FU 60 ALL 57. METHOD ASD 58. STP 2 MEMB 2 59. TRACK 2 MEMB 2 60. CHECK CODE MEMB 2 PARAMETER 2 STAAD SPACE -- PAGE NO. 13 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). STAAD SPACE -- PAGE NO. 14 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 |-----------------------------------------------------------------------------| | Member No: 2 Profile: PRISMAT (AISC SECTIONS)| | Status: PASS Ratio: 0.501 Loadcase: 1 | | Location: 60.00 Ref: Cl.G1 | | Pz: 10.23 C Vy: -67.19 Vx: 0.000 | | Tz: 0.000 My: 0.000 Mx: 505.7 | |-----------------------------------------------------------------------------| | COMPRESSION SLENDERNESS | | Actual Slenderness Ratio : 17.839 | | Allowable Slenderness Ratio : 200.000 LOC : 60.00 | |-----------------------------------------------------------------------------| | STRENGTH CHECKS | | Critical L/C : 1 Ratio : 0.501(PASS) | | Loc : 60.00 Condition : Cl.G1 | |-----------------------------------------------------------------------------| | SECTION PROPERTIES (LOC: 60.00, PROPERTIES UNIT: IN ) | | Ag : 1.492E+01 Axx : 7.909E+00 Ayy : 7.909E+00 | | Ixx : 1.688E+02 Iyy : 1.688E+02 J : 3.376E+02 | | Sxx+: 3.376E+01 Sxx-: 3.376E+01 Zxx : 4.517E+01 | | Syy+: 3.376E+01 Syy-: 3.376E+01 Zyy : 4.517E+01 | | Cw : 0.000E+00 x0 : 0.000E+00 y0 : 0.000E+00 | |-----------------------------------------------------------------------------| | MATERIAL PROPERTIES | | Fyld: 50.000 Fu: 60.000 | |-----------------------------------------------------------------------------| | Actual Member Length: 60.000 | | Design Parameters (Built-Up) | | Kx: 1.00 Ky: 1.00 NSF: 1.00 SLF: 0.80 CSP: 12.00 | |-----------------------------------------------------------------------------| | COMPRESSION CLASSIFICATION (L/C: 2 LOC: 60.00) | | λ λp λr CASE | | Flange: NonSlender 20.00 N/A 63.80 Table.B4.1a.Case9 | | Web : NonSlender 20.00 N/A 63.80 Table.B4.1a.Case9 | | | | FLEXURE CLASSIFICATION (L/C: 2 LOC: 60.00) | | λ λp λr CASE | | Flange: Compact 20.00 40.60 179.80 Table.B4.1b.Case20 | | Web : Compact 20.00 40.60 179.80 Table.B4.1b.Case20 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 15 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL TENSION | |-----------------------------------------------------------------------------| | TENSILE YIELDING | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.000 446.8 0.000 Cl.D2 1 60.00 | | | | Intermediate Results : | | Nom. Ten. Yld Cap : Pn = 746.13 kip Eq.D2-1 | |-----------------------------------------------------------------------------| | TENSILE RUPTURE | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.000 358.1 0.000 Cl.D2 1 60.00 | | | | Intermediate Results : | | Effective area : Ae = 11.938 in2 Eq.D3-1 | | Nom. Ten. Rpt Cap : Pn = 716.28 kip Eq.D2-2 | |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL COMPRESSION | |-----------------------------------------------------------------------------| | FLEXURAL BUCKLING X | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 23.86 436.5 0.055 Cl.E3 2 60.00 | | | | Intermediate Results : | | Effective Slenderness : Lcx/rx = 17.839 Cl.E2 | | Elastic Buckling Stress : Fex = 899.40 ksi Eq.E3-4 | | Crit. Buckling Stress : Fcrx = 48.850 ksi Eq.E3-2 | | Nom. Flexural Buckling : Pnx = 728.97 kip Eq.E3-1 | |-----------------------------------------------------------------------------| | FLEXURAL BUCKLING Y | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 23.86 436.5 0.055 Cl.E3 2 60.00 | | | | Intermediate Results : | | Effective Slenderness : Lcy/ry = 17.839 Cl.E2 | | Elastic Buckling Stress : Fey = 899.40 ksi Eq.E3-4 | | Crit. Buckling Stress : Fcry = 48.850 ksi Eq.E3-2 | | Nom. Flexural Buckling : Pny = 728.97 kip Eq.E3-1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 16 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR SHEAR | |-----------------------------------------------------------------------------| | SHEAR ALONG X | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 0.5390E-01 134.0 0.000 Cl.G1 2 60.00 | | | | Intermediate Results : | | Nom. Shear Along X : Vnx = 223.84 kip Eq.G5-1 | | Crit. Stress Fcr Along X : Fcrx = 30.000 ksi Eq.G5-2 | |-----------------------------------------------------------------------------| | SHEAR ALONG Y | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 67.19 134.0 0.501 Cl.G1 1 60.00 | | | | Intermediate Results : | | Nom. Shear Along Y : Vny = 223.84 kip Eq.G5-1 | | Crit. Stress Fcr Along Y : Fcrx = 30.000 ksi Eq.G5-2 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 17 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR BENDING | |-----------------------------------------------------------------------------| | FLEXURAL YIELDING (X) | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 505.7 1352. 0.374 Cl.F8.1 1 60.00 | | | | Intermediate Results : | | Nom Flex Yielding Along X : Mnx = 2258.3 kip-in Eq.F8-1 | |-----------------------------------------------------------------------------| | FLEXURAL YIELDING (Y) | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | -1.617 1352. 0.001 Cl.F8.1 2 60.00 | | | | Intermediate Results : | | Nom Flex Yielding Along Y : Mny = 2258.3 kip-in Eq.F8-1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 18 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR AXIAL BEND INTERACTION | |-----------------------------------------------------------------------------| | COMBINED FORCES CLAUSE H1 | | RATIO CRITERIA L/C LOC | | 0.386 Eq.H1-1b 1 60.00 | | | | Intermediate Results : | | Axial Capacity : Pc = 436.51 kip Cl.H1.1 | | Moment Capacity : Mcx = 1352.3 kip-in Cl.H1.1 | | Moment Capacity : Mcy = 1352.3 kip-in Cl.H1.1 | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 19 STAAD.PRO CODE CHECKING - AISC 360-16 ASD (V1.2) **************************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted). - Member : 2 Contd. |-----------------------------------------------------------------------------| | CHECKS FOR TORSION | |-----------------------------------------------------------------------------| | TORSION CAPACITY | | DEMAND CAPACITY RATIO REFERENCE L/C LOC | | 238.5 1273. 0.187 Cl.H3.1 2 60.00 | | | | Intermediate Results : | | Crit. Stress. Fcr : Fcr = 30.000 ksi Cl.H3.1(a) | | Nom. Strength : Tn = 2126.5 kip-in Eq.H3-1 | |-----------------------------------------------------------------------------| ***NOTE : AISC 360-16 Design Statement for STAAD.Pro. *** AXIS CONVENTION ***: ======================== The capacity results and intermediate results in the report follow the notations and axes labels as defined in the AISC 360-16 code. The analysis results are reported in STAAD.Pro axis convention and the AISC 360:16 design results are reported in AISC 360-16 code axis convention. AISC Spec. STAAD.Pro Description ------------ ----------- ------------- X Z Axis typically parallel to the sections principal major axis. Y Y Axis typically parallel to the sections principal minor axis. Z X Longitudinal axis perpendicular to the cross section. SECTION FORCES AXIS MAPPING: - AISC Spec. STAAD.Pro Description ------------ ----------- ------------- Pz FX Axial force. Vy FY Shear force along minor axis. Vx FZ Shear force along major axis. Tz MX Torsional moment. My MY Bending moment about minor axis. Mx MZ Bending moment about major axis. *** DESIGN MESSAGES ***: ======================= 1. Section classification reported is for the cross section and loadcase that produced the worst case design ratio for flexure/compression Capacity results. 2. Results for any Capacity/Check that is not relevant for a section/loadcase based on the code clause in AISC 360-16 will not be shown in the report. 3. Bending results are reported as being �about� the relevant axis (X/Y), while the results for shear are reported as being for shear forces �along� the axis. E.g : Mx indicates bending about the X axis, while Vx indicates shear along the X axis. *** ABBREVIATIONS ***: ====================== F-T-B = Flexural-Torsional Buckling L-T-B = Lateral-Torsional Buckling F-L-B = Flange Local Buckling W-L-B = Web Local Buckling L-L-B = Leg Local Buckling C-F-Y = Compression Flange Yielding T-F-Y = Tension Flange Yielding