D5.C.6 Design Parameters

Design parameters communicate specific design decisions to the program. They are set to default values to begin with and may be altered to suite the particular structure.

Depending on the model being designed, you may have to change some or all of the parameter default values. Some parameters are unit dependent and when altered, the n setting must be compatible with the active "unit" specification.

The follow table lists all the relevant EC3 parameters together with description and default values.

| Parameter Name | Default Value | Description |

|---|---|---|

| CODE | - |

Must be specified as EN 1993-1-1:2005 to invoke design per Eurocode 3:2005 (EN 1993). Design code to follow. See TR.48.1 Parameter Specifications. |

| ALH | 0.5 | The ratio of the distance of the point torque (from the start of the member) to the length of the member. The default value of 0.5 represents torque acting at the mid-span of a symmetrically loaded member. Values can range from 0 to 1. |

| ALPHA | 1.0 | Used to input a user defined value for the α factor in equation 6.41 for combined bending and axial force checks. |

| BEAM | 3 |

Parameter to control the number of sections to checked along the length of a beam:

|

| BETA | 1.0 | Used to input a user defined value for the β factor in equation 6.41 for combined bending and axial force checks. |

| C1 | 1.132 | Corresponds to the C1 factor to be used to calculate Elastic critical moment Mcr as per Clause 6.3.2.2 |

| C2 | 0.459 | Corresponds to the C2 factor to be used to calculate Elastic critical moment Mcr as per Clause 6.3.2.2 |

| C3 | 0 | Corresponds to the C3 factor to be used to calculate Elastic critical moment Mcr as per Clause 6.3.2.2 |

| CAN | 0 |

Member will be considered as a cantilever type member for deflection checks.

|

| CMM | 1.0 |

Indicates type of loading and support conditions on member. Used to calculate the C1, C2, and C3 factors to be used in the Mcr calculations. Can take a value from 1 to 8. Refer to Note 2 (below) for more information on its use. |

| CMN | 1.0 |

Indicates the level of End-Restraint.

|

| CMT | 1 |

Used to indicate the loading and support condition for torsion (ref. SCI publication P-057). Can take a value of 1-7. The values correspond to the various cases defined in section 6 and App. B of SCI-P-057. Refer to Note 4 (below) for more information |

| DFF | 360 | "Deflection Length" / Max..

allowable local deflection See Note 1d below. See TR.40 Load Envelope for deflection checks using serviceability load envelopes. |

| DJ1 | Start Jointof member | Joint No. denoting starting point for calculation of "Deflection Length". See Note 1 below. |

| DJ2 | End Joint of member | Joint No. denoting end point for calculation of "Deflection Length". See Note 1 below. |

| DMAX | 100.0 cm | Maximum allowable depth for the member. |

| DMIN | 0 | Minimum required depth for the member. |

| EFT | Member Length | The distance between the adjacent torsional

restraints. Effective length for torsion, lateral-torsional buckling check of

tapered members per Annex BB 3.2.2. A value of 0 defaults to the member length. |

| ELB | 0 |

Used to specify the method for combined axial load + bending checks

|

| ESTIFF | 0 |

(For use with the Dutch NA only) Method for checking columns forming part of (non)/buttressed framework:

Refer to D5.D.3.8 Clause 6.33 – Uniform members in bending and axial compression for additional description on this parameter. |

| FAB | 3 |

Used to specify the fabrication class to be used to check for slender (Class 4) CHS/pipe sections (EN 1993-1-6:2007)

|

| FU | 0 | Ultimate tensile strength of steel. |

| GM0 | 1.0 | Corresponds to the γm0 factor in EN 1993-1-1:2005 |

| GM1 | 1.0 | Corresponds to the γm1 factor in EN 1993-1-1:2005 |

| GM2 | 1.25 | Corresponds to the γm2 factor in EN 1993-1-1:2005 |

| GST | 0 |

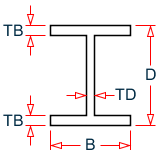

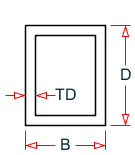

Used to specify the section type to be used for designing a "general section" from a user-provided table. The member will be considered as the specified type with the user-defined properties. Where design related checks on section geometry are required (e.g., depth/thickness ratio or width/thickness ratio), the values of B, D, TB, and TD are used as indicated and this is noted in the output file. The available options and corresponding required UPT general section values are as below. If the required dimensions are not provided, a warning is issued in the output file in the design results for the section with the GST parameter. |

| HGT | 0.0 | Distance from the top of the tapered web section to the

center of gravity of purlin.

Used for the lateral-torsional buckling calculations for web-tapered members. |

| KC | 1.0 |

Corresponds to the correction factor as per Table 6.6 of EN 1993-1-1:2005. Program will calculate kc automatically if this parameter is set to 0. |

| KY | 1.0 | K factor in local y axis. Used to calculate the effective length for slenderness and buckling calculations. |

| KZ | 1.0 | K factor in local z axis. Used to calculate the effective length for slenderness and buckling calculations. |

| LEG | 0 |

Slenderness values for angles as determined from BS 5950-2000 Table 25. Valid range from 0 – 7 and 10-11. Refer to D3.B.6 Design Parameters |

| LVV | Member length | Applicable for double angles measured between

interconnecting bolts for back-to-back struts or between end welds or end bolts

of adjacent battens (Table 25, BS 5950-2000). The default is the member's length. |

| LY | Member Length | Compression length in local y axis between

lateral restraints Slenderness ratio = KY×LY / Ryy Distance between lateral restraints used for tapered I sections. Used for the lateral-torsional buckling calculations for web-tapered members. The default is the member's length. |

| LZ | Member Length | Compression length in local z axis between

lateral restraints Slenderness ratio = KZ×LZ / Rzz |

| MTH | 0 |

Used to select the clause to be used to calculate the LTB reduction factor, χLT. The available options and corresponding values are as below:

By default, the program will use Cl 6.3.2.3 for rolled & built-up I-sections and Cl. 6.3.2.2 for all other sections. If, however, the specified National Annex expands on Cl. 6.3.2.3 to include other section types (e.g., the UK NA), the program will use Cl. 6.3.2.3 by default for that particular section type. Refer to D5.D. European Codes - National Annexes to Eurocode 3 [EN 1993-1-1:2005] for additional details on NA documents. |

| MU | 0 |

The ratio of the moment due to the transverse force to the maximum moment M. To be used with CMM values of 7 and 8. See Note 2 (below). |

| NA | 0 |

Choice of National Annex to be used for EC3 design. Refer to D5.D. European Codes - National Annexes to Eurocode 3 [EN 1993-1-1:2005] for values allowed for this parameter. (Refer to D5.C.1 General Description for more information) |

| NSF | 1.0 | Net tension factor for tension capacity calculation. |

| PLG | 0 |

To be used to determine whether to include the additional interaction checks as per CL. NA.20(2) and NA.20(3) of the Polish National Annex. |

| PY | Yield Strength | The yield strength default value is set based on the default value of the SGR parameter. |

| RATIO | 1 | Permissible ratio of loading to capacity. |

| SBLT | 0.0 |

Indicates if the section is rolled or built-up.

|

| SGR | 0 |

Steel grade as in Table 3.1: EN 1993-1-1: 2005:

|

| STIFF | Member Length or depth of beam, whichever is lesser | Distance between transverse stiffener plates, used to prevent web shear buckling. If not specified or if a value of 0 is provided, the program will assume the web is unstiffened. |

| TOM | 0 | Total torsion for design used for torsion checks. Can be used to override the total torsional moment to be used for member design. |

| TORSION | 0 |

Method to be used for a specific member or group of members:

|

| TRACK | 0 |

Specify level of detail in output.

|

| UNF | 1 | Unsupported length provided as a fraction of actual member length used for lateral-torsional buckling calculation. |

| UNL | Member Length | Unsupported length for calculating allowable bending stress. Used for the lateral-torsional buckling calculation. Value should be in the current units of length. |

| ZG | +Section Depth/2 |

Distance of transverse load from shear center. Used to calculate Mcr. |

Notes

-

CAN, DJ1, and DJ2 – Deflection

-

When performing the deflection check, you can choose between two methods. The first method, defined by a value 0 for the CAN parameter, is based on the local displacement. Refer to TR.44 Printing Section Displacements for Members for details on local displacement..

If the CAN parameter is set to 1, the check will be based on cantilever style deflection. Let (DX1, DY1, DZ1) represent the nodal displacements (in global axes) at the node defined by DJ1 (or in the absence of DJ1, the start node of the member). Similarly, (DX2, DY2, DZ2) represent the deflection values at DJ2 or the end node of the member.

Compute Delta = SQRT((DX2 - DX1)2 + (DY2 - DY1)2 + (DZ2 - DZ1)2)

Compute Length = distance between DJ1 & DJ2 or, between start node and end node, as the case may be.

Then, if CAN is specified a value 1, dff = L/Delta

Ratio due to deflection = DFF/dff

-

If CAN = 0, deflection length is defined as the length that is used for calculation of local deflections within a member. It may be noted that for most cases the Deflection Length will be equal to the length of the member. However, in some situations, the Deflection Length may be different. A straight line joining DJ1 and DJ2 is used as the reference line from which local deflections are measured.

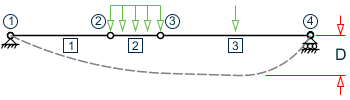

For example, refer to the figure below where a beam has been modeled using four joints and three members. The "Deflection Length" for all three members will be equal to the total length of the beam in this case. The parameters DJ1 and DJ2 should be used to model this situation. Thus, for all three members here, DJ1 should be 1 and DJ2 should be 4. D = Maximum local deflection for members 1, 2, and 3.PARAMETERS DFF 300. ALL DJ1 1 ALL DJ2 4 ALL

-

If DJ1 and DJ2 are not used, "Deflection Length" will default to the member length and local deflections will be measured from original member line.

-

If a serviceability load envelope is specified under "LOAD LIST ENV" before a parameter block, the default value of DFF 360 is used for deflection calculations. If DFF 0 is specified for any member, then the deflection check is skipped for that member.

-

The above parameters may be used in conjunction with other available parameters for steel design.

-

-

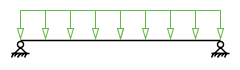

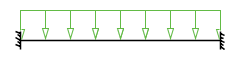

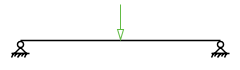

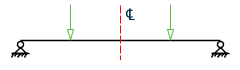

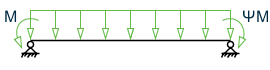

The values of CMM for various loading and support conditions are as given below:

Table 2. Values for the CMM Parameter CMM Value Loading and Support Conditions 1

2

3

4

5

6

7

varying end moments and uniform loading

8

varying end moments and central point load

Checking beam deflection

With the TRACK parameter set to 4, the members included in a BEAM CHECK command will be checked for the local axis deflection rather than for the stress capacity using the current LOAD LIST.

If LOAD LIST ENV is used, then serviceability envelope must be present to check for deflections. If only strength load cases are given in LOAD LIST ENV, only strength checks will be performed and TRACK 4 is treated as TRACK 2.-

The values of CMT for various loading and support conditions are as given below:

Table 3. Loading and Support Conditions represented by CMT Parameter Values CMT Value

Description Diagram 1 (Default) : Concentrated Torque at Ends. Ends Torsion fixed and Warping fixed

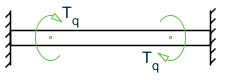

2 Concentrated Torque along length of member. Ends Torsion fixed and Warping free

3 Concentrated Torque along length of member. Ends Torsion fixed and Warping fixed

4 Uniform Torque in member. Ends Torsion fixed and Warping free

5 Uniform Torque in member. Ends Torsion fixed and Warping fixed

6 Concentrated Torque in cantilever. End Torsion fixed and Warping fixed

7 Uniform Torque in cantilever. End Torsion fixed and Warping fixed  Note: For CMT = 2 and CMT = 3, you have the option of specifying the distance at which the concentrated torque acts, measured from the start of the member. This can be done by using the ALH design parameter. The ALH parameter indicates the ratio of the distance of the point torque (from the start of the member) to the length of the member. This parameter will have a default value of 0.5 (i.e., the torque acts at the center of the span) and will accept values ranging from 0 to 1.

Note: For CMT = 2 and CMT = 3, you have the option of specifying the distance at which the concentrated torque acts, measured from the start of the member. This can be done by using the ALH design parameter. The ALH parameter indicates the ratio of the distance of the point torque (from the start of the member) to the length of the member. This parameter will have a default value of 0.5 (i.e., the torque acts at the center of the span) and will accept values ranging from 0 to 1.