V. AISI 2016 2CU F2F Compressive Strength

Verify the axial compressive strength of a double cold-formed channel section according to the AISI S100 2016 specification using both the LRFD and ASD methods.

Details

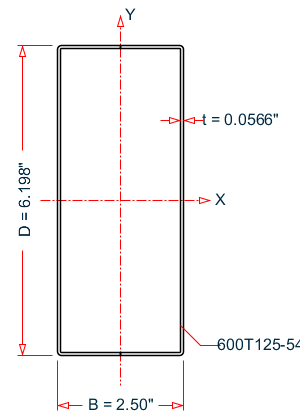

The member is 10 ft long cantilever. The section used is a pair of 600T125-54 channels in a front-to-front configuration (no spacing between channel toes).

Section Properties

Properties of a 600T125-54 (listed as a 600CU125-54 in STAAD.Pro):

- Depth, D = 6.198 in

- Flange width, B = 1.250 in

- Thickness, t = 0.0566 in

- Inner radius, R = 0.0849 in.

- Cross-section area, A = 0.48 in2

- Moment of inertia about the Z axis, Iz = 2.34 in4

- Moment of inertia about the Y axis, Iy = 0.0539 in4

- Heel to C.G. distance, x = 0.204 in

- Torsional constant, J = 0.000513 in4

- Warping constant, Cw = 0.348 in6

Material Properties

- E = 29,000 ksi

- G = 11,200 ksi

- Fy = 36 ksi

- Fu = 58 ksi

Calculations

Section Properties

- Average radius, r = R + t/2 = 0.0849 + 0.0566 / 2 = 0.113 in.

- Clear depth of web, a = D = (2×r + t) = 6.198 - (2× 0.113 + 0.0566) = 5.915 in.

- Clear width of the flanges, b = B - (r + t/2) = 1.25 - (0.113 + 0.0556 / 2) = 1.109 in.

- Cross-section area, A = 2× 0.48 = 0.96 in2

- Moment of inertia about the Z axis, Iz = 2× 2.34 = 4.68 in4

- Moment of inertia about the Y axis, Iy = 2[0.0539 + 0.48×(1.25 - 0.204)2] = 1.158 in4

- Radius of gyration about the Z axis,

- Radius of gyration about the Y axis,

- Torsional constant, J = 2× 0.000513 = 0.00103 in4

- Center-to-center depth,

- Center-to-edge flange width,

- Warping constant, (Taken from Table 10.2, Case 4 of Reference 2; simplified for the case where h = 2×h1)

Compression Capacity for Yielding and Global Buckling

About the major axis:

The elastic flexural buckling stress

| (Eq. E2.1-1) |

| (Eq. E2-4) |

Since λcz < 1.5, the compressive strength is given by:

| (Eq. 2-2) |

About the minor axis:

The elastic flexural buckling stress

| (Eq. E2.1-1) |

| (Eq. E2-4) |

Since λcy < 1.5, the compressive strength is given by:

| (Eq. 2-2) |

The controlling compressive stress is the minimum of Fnz and Fny: Fn = 19.20 ksi

The nominal axial compressive strength, Pne = A × Fn = 0.96 × 19.20 = 18.43 kips

- LRFD: ϕcPne = 0.85 × 18.43 = 15.67 kips

- ASD: Pne/Ωc = 18.43 / 1.8 = 10.24 kips

Compression Capacity in Local Buckling

Global column stress about major axis (as defined in Section E2):

Fn = Fny = 19.20 ksi

Determine the effective area, Ae as per Appendix 1. The flanges of a front-to-front channel are considered stiffened elements.

Compression flange effective width:

| w = b = 1.109 in | (AISC Manual 3.3.2) |

| (E1. 1.1-4) |

| = | ||

| = |

The slenderness factor:

| (Eq. 1.1-3) |

As λ < 0.673, the local reduction factor, ρ = 1. Therefore, the effective width of the compression flange is bf = ρ×w = 1.109 in.

Web effective width:

| w = a = 5.915 in | (AISC Manual 3.3.2) |

Therefore, the effective width of the compression flange is bw = ρ×w = 0.597 × 5.915 = 3.532 in

The total effective area is the gross area minus the difference in nominal widths and effective widths:

Ae = A - 4×(b - bf)t - 2×(a - bw)t = 0.96 - 4×(1.109 - 1.109)×0.0566 - 2×(5.915 - 3.532)×0.0566 = 0.69 in.2

| (Eq. E3.1-1) |

- LRFD: ϕcPnℓ = 0.85 × 11.26 = kips

- ASD: Pnℓ/Ωc = 13.26 / 1.8 = 7.36 kips

Comparison

| Result Type | Reference | STAAD.Pro | Difference | Comments | |

|---|---|---|---|---|---|

| LRFD | Axial comp. per section E2 (kips) | 15.67 | 15.671 | negligible | |

| Local comp. per section E3 (kips) | 11.26 | 11.283 | negligible | ||

| ASD | Axial comp. per section E2 (kips) | 10.24 | 10.242 | negligible | |

| Local comp. per section E3 (kips) | 7.36 | 7.375 | negligible | ||

STAAD Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\09 Steel Design\US\AISI\AISI 2016 2CU F2F Compressive Strength.STD is typically installed with the program.

- The material properties for design are specified by the parameters FYLD 36 and FU 58.

- A member with unreinforced webs is specified using TSA 0

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 11-Jan-22

ENGINEER NAME TK

END JOB INFORMATION

INPUT WIDTH 79

UNIT FEET KIP

JOINT COORDINATES

1 0 0 0; 2 10 0 0;

MEMBER INCIDENCES

1 1 2;

DEFINE MATERIAL START

ISOTROPIC STEEL

E 4.176e+06

POISSON 0.3

DENSITY 0.489024

ALPHA 6.5e-06

DAMP 0.03

G 1.6128e+06

TYPE STEEL

STRENGTH RY 1.5 RT 1.2

END DEFINE MATERIAL

UNIT INCHES KIP

MEMBER PROPERTY COLDFORMED AMERICAN

1 TABLE FR 600CU125-54

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 FIXED

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

JOINT LOAD

2 FX 10

PERFORM ANALYSIS

PARAMETER 1

CODE AISI 2016

METHOD LRFD

FYLD 36 ALL

FU 58 ALL

FLX 0 ALL

TSA 0 ALL

TRACK 2 ALL

CHECK CODE ALL

PARAMETER 2

CODE AISI 2016

METHOD ASD

FYLD 36 ALL

FU 58 ALL

FLX 0 ALL

TSA 0 ALL

TRACK 2 ALL

CHECK CODE ALL

FINISH

STAAD Output

STAAD.Pro CODE CHECKING - (AISI S100-16) [LRFD] (v1.0) ******************************************************** ALL UNITS ARE IN "INCH" AND "KIP " (U.N.O.) |-----------------------------------------------------------------------------| | MEMBER: 1 SECTION:FR 600CU125-54 LEN: 120.000 LOC: 0.000 | | STATUS: PASS RATIO: 0.322 REF: Sec. D2 LC: 1 | |-----------------------------------------------------------------------------| | DESIGN FORCES: | | Location: 0.000 Criteria: Sec. D2 LC: 1 | | Fx:(T) -10.000 Fy: 0.000 Fz: 0.000 | | Mx: 0.000 My: 0.000 Mz: 0.000 | |-----------------------------------------------------------------------------| | SECTION PROPERTIES: | | Ag: 0.96000 Az: 0.25096 Ay: 0.66958 | | Cz: 0.00000 Cy: 0.00000 | | Iz: 4.68000 Iy: 1.15815 J: 0.00104 | | Sz: 1.51016 Sy: 0.92652 | | Rz: 2.20794 Ry: 1.09837 Cw: 0.00000 | |-----------------------------------------------------------------------------| | MATERIAL INFO: | | Fy: 36.000 Fu: 58.000 E: 29000.000 G: 11200.000 | |-----------------------------------------------------------------------------| | DESIGN PROPERTIES: | | Member Length: 120.000 Lz: 120.000 Ly: 120.000 Lb: 0.000 | | DESIGN PARAMETERS: | | Kz: 1.000 Ky: 1.000 NSF: 1.000 | |-----------------------------------------------------------------------------| | CRITICAL SLENDERNESS: | |-----------------------------------------------------------------------------| | LC : 1 Actual : 109.253 Allowable : 300.000 Ratio : 0.364 | |-----------------------------------------------------------------------------| | Section Dimension Check | Ratio | Limit | Status | |-----------------------------------------------------------------------------| | Radius To Thickness Ratio | 1.500 | 10.000 | PASS | | Width To Thickness Ratio | 17.085 | 500.000 | PASS | | Web Depth To Thickness Ratio | 104.505 | 200.000 | PASS | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 4 STAAD.Pro CODE CHECKING - (AISI S100-16) [LRFD] (v1.0) ******************************************************** ALL UNITS ARE IN "INCH" AND "KIP " (U.N.O.) | - MEMBER: 1 (Contd.....) | | | |-----------------------------------------------------------------------------| | Limit States | Load# |Location| Demand | Capacity |Ratio| Reference | |--------------------|-------|--------|----------|----------|-----|-----------| | Tension | 1 | 0.00 | -10.000 | 31.104 |0.322|Sec. D2 | | Yielding | 1 | 0.00 | -10.000 | 31.104 |0.322|Sec. D2 | | Rupture | 1 | 0.00 | -10.000 | 41.760 |0.239|Sec. D3 | | Compression | - | - | - | 11.283 | - |Sec. E3 | | Local Comp | - | - | - | 11.283 | - |Sec. E3 | | Axial Comp | - | - | - | 15.671 | - |Sec. E2 | | Bending | - | - | - | 14.721 | - |Sec. F2 | | Major Local Bend | - | - | - | 14.756 | - |Sec. F3 | | Minor Local Bend | - | - | - | 14.846 | - |Sec. F3 | | Major Sectional | - | - | - | 48.929 | - |Sec. F2 | | Minor Sectional | - | - | - | 30.019 | - |Sec. F2 | | LTB Major | - | - | - | 14.721 | - |Sec. F2 | | LTB Minor | - | - | - | 23.956 | - |Sec. F2 | | Shear | - | - | - | 5.150 | - |Sec. G2 | | Major Shear (Z) | - | - | - | 5.150 | - |Sec. G2 | | Minor Shear (Y) | - | - | - | 8.154 | - |Sec. G2 | | Interaction | 1 | 0.00 | - | - |0.322|Eq. H1.1-1 | | (Bend+Ten) Int1 | 1 | 0.00 | - | - |0.322|Eq. H1.1-1 | |-----------------------------------------------------------------------------| 43. PARAMETER 2 44. CODE AISI 2016 45. METHOD ASD 46. FYLD 36 ALL 47. FU 58 ALL 48. FLX 0 ALL 49. TSA 0 ALL 50. TRACK 2 ALL 51. CHECK CODE ALL STEEL DESIGN WARNING # 14 ~ Channel front to front member # 1 will be considered welded throughout length. Spacing will not be considered. STAAD SPACE -- PAGE NO. 5 STAAD.Pro CODE CHECKING - (AISI S100-16) [ASD ] (v1.0) ******************************************************** ALL UNITS ARE IN "INCH" AND "KIP " (U.N.O.) |-----------------------------------------------------------------------------| | MEMBER: 1 SECTION:FR 600CU125-54 LEN: 120.000 LOC: 0.000 | | STATUS: PASS RATIO: 0.483 REF: Sec. D2 LC: 1 | |-----------------------------------------------------------------------------| | DESIGN FORCES: | | Location: 0.000 Criteria: Sec. D2 LC: 1 | | Fx:(T) -10.000 Fy: 0.000 Fz: 0.000 | | Mx: 0.000 My: 0.000 Mz: 0.000 | |-----------------------------------------------------------------------------| | SECTION PROPERTIES: | | Ag: 0.96000 Az: 0.25096 Ay: 0.66958 | | Cz: 0.00000 Cy: 0.00000 | | Iz: 4.68000 Iy: 1.15815 J: 0.00104 | | Sz: 1.51016 Sy: 0.92652 | | Rz: 2.20794 Ry: 1.09837 Cw: 0.00000 | |-----------------------------------------------------------------------------| | MATERIAL INFO: | | Fy: 36.000 Fu: 58.000 E: 29000.000 G: 11200.000 | |-----------------------------------------------------------------------------| | DESIGN PROPERTIES: | | Member Length: 120.000 Lz: 120.000 Ly: 120.000 Lb: 0.000 | | DESIGN PARAMETERS: | | Kz: 1.000 Ky: 1.000 NSF: 1.000 | |-----------------------------------------------------------------------------| | CRITICAL SLENDERNESS: | |-----------------------------------------------------------------------------| | LC : 1 Actual : 109.253 Allowable : 300.000 Ratio : 0.364 | |-----------------------------------------------------------------------------| | Section Dimension Check | Ratio | Limit | Status | |-----------------------------------------------------------------------------| | Radius To Thickness Ratio | 1.500 | 10.000 | PASS | | Width To Thickness Ratio | 17.085 | 500.000 | PASS | | Web Depth To Thickness Ratio | 104.505 | 200.000 | PASS | |-----------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 6 STAAD.Pro CODE CHECKING - (AISI S100-16) [ASD ] (v1.0) ******************************************************** ALL UNITS ARE IN "INCH" AND "KIP " (U.N.O.) | - MEMBER: 1 (Contd.....) | | | |-----------------------------------------------------------------------------| | Limit States | Load# |Location| Demand | Capacity |Ratio| Reference | |--------------------|-------|--------|----------|----------|-----|-----------| | Tension | 1 | 0.00 | -10.000 | 20.695 |0.483|Sec. D2 | | Yielding | 1 | 0.00 | -10.000 | 20.695 |0.483|Sec. D2 | | Rupture | 1 | 0.00 | -10.000 | 27.840 |0.359|Sec. D3 | | Compression | - | - | - | 7.375 | - |Sec. E3 | | Local Comp | - | - | - | 7.375 | - |Sec. E3 | | Axial Comp | - | - | - | 10.242 | - |Sec. E2 | | Bending | - | - | - | 9.795 | - |Sec. F2 | | Major Local Bend | - | - | - | 9.818 | - |Sec. F3 | | Minor Local Bend | - | - | - | 9.878 | - |Sec. F3 | | Major Sectional | - | - | - | 32.554 | - |Sec. F2 | | Minor Sectional | - | - | - | 19.973 | - |Sec. F2 | | LTB Major | - | - | - | 9.795 | - |Sec. F2 | | LTB Minor | - | - | - | 15.939 | - |Sec. F2 | | Shear | - | - | - | 3.388 | - |Sec. G2 | | Major Shear (Z) | - | - | - | 3.388 | - |Sec. G2 | | Minor Shear (Y) | - | - | - | 5.364 | - |Sec. G2 | | Interaction | 1 | 0.00 | - | - |0.483|Eq. H1.1-1 | | (Bend+Ten) Int1 | 1 | 0.00 | - | - |0.483|Eq. H1.1-1 | |-----------------------------------------------------------------------------|