V. AISC 360-05 UPT Square Hollow Section

Verify the axial compression capacity, shear capacity, flexure capacity, torsional capacity, and interaction ratio of a user-provided hollow square section member per both the LRFD and ASD methods of the AISC 360-05 code.

Details

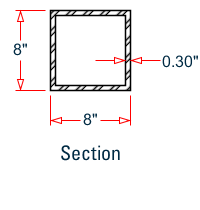

A 5' × 5' portal frame consists of W12x72 columns and a UPT SHS member for the beam. The section outer depth, D, is 8" and the thickness, t, is 0.30".

- E = 29,000 ksi

- Fy = 50 ksi

Validation

Design Forces

Section Properties

- Inner depth, d = 8 - 2×0.30 = 7.40 in.

- Area,

- Shear area, Aw = 2×D×tw = 4.80 in2

- Moment of inertia,

- Elastic section modulus,

- Radius of gyration,

- Plastic section modulus,

- HSS Torsional constant,

Section Classification

The design thickness, t = 0.93×tw = 0.279 in

The design depth, d = D - 3t = 7.163 in

Flange in compression

Per Table 4.1a Case 6, , therefore flanges are non-slender for compression. Similar for the web of the square section.

Flexure classification of flange:

Per Table B4.1-12, , therefore flange is compact for bending.

Flexure classification of web:

Per Table B4.1-13, , therefore web is compact for bending.

Compression Capacity

Effective slenderness ratio:

Elastic buckling stress:

| (Eq. E3-4) |

Critical buckling stress:

| (Eq. E3-2) |

Nominal buckling strength:

| Pn = Ag× Fcr = 9.24 × 48.68 = 449.9 kips | (Eq. E3-1) |

- The ultimate compression capacity (LRFD) = ϕcPn = 0.9 × 449.9 = 404.9 kips

- The allowable compression capacity (ASD) = Pn/Ωc = 449.9 / 1.67 = 269.4 kips

Calculate Shear Capacity

The nominal shear strength:| Vn = 0.6× Fy × Aw × Cv2 | (Eq. G4-1) |

| = |

Vn = 0.6 (50) (4.80) (1.0) = 144 kips

The shear capacity:- The ultimate shear capacity (LRFD) = ϕvVn = 0.9 × 144 = 129.6 kips

- The allowable shear capacity (ASD) = Vn/Ωv = 144 / 1.67 = 86.23 kips

Calculate Bending Capacity

Bending capacity in plastic yielding (compact section):

| Mp = Fy × Zx = 50 × 26.69 = 1,335 in·kips | (Eq F7-1) |

- The ultimate bending capacity (LRFD) = ϕbMy = 0.9 × 1,335 = 1,201 in·kips

- The allowable bending capacity (ASD) = My/Ωb = 1,335 / 1.67 = 799.2 in·kips

Torsional Capacity

Fcr = 0.6Fy = 30 ksi

Nominal torsional capacity:

Tn = Fcr × C = 1,064 ksi

The torsional capacity:- The ultimate torsional capacity (LRFD) = ϕTTn = 0.9 × 1,064 = 957.7 kips

- The allowable torsional capacity (ASD) = Tn/ΩT = 1,064 / 1.67 = 637.2 kips

Interaction Ratio for Bending and Compression

Check the interaction ratio for Load Case 1:

So use Eq. H1-1b for both methods: .

Results

| Result Type | Reference | STAAD.Pro | Difference | Comments | |

|---|---|---|---|---|---|

| LRFD | Compression capacity (kips) | 404.9 | 405 | negligible | |

| Bending capacity (in·kips) | 1,201 | 1,200 | negligible | ||

| Shear capacity (kips) | 129.6 | 130 | negligible | ||

| Torsional capacity (in·kips) | 957.7 | 958 | negligible | ||

| Interaction ratio | 0.514 | 0.514 | negligible | ||

| ASD | Compression capacity (kips) | 269.4 | 269 | negligible | |

| Bending capacity (in·kips) | 799.2 | 799 | negligible | ||

| Shear capacity (kips) | 86.23 | 86.2 | negligible | ||

| Torsional capacity (in·kips) | 637.2 | 637 | negligible | ||

| Interaction ratio | 0.765 | 0.772 | negligible | ||

STAAD.Pro Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\09 Steel Design\US\AISC\AISC 360-05 UPT Square Hollow Section.STD is typically installed with the program.

The following design parameters are used:

- The welded SHS member is specified using STP 2

- Shear lag factor, U for tension rupture capacity is specified by SLF 0.8

The remaining parameters all use their default values.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 13-Apr-21

END JOB INFORMATION

INPUT WIDTH 79

UNIT INCHES KIP

JOINT COORDINATES

1 0 0 0; 2 0 60 0; 3 60 60 0; 4 60 0 0;

MEMBER INCIDENCES

1 1 2; 2 2 3; 3 3 4;

START USER TABLE

TABLE 1

UNIT INCHES KIP

TUBE

SHS

9.24 8 8 0.3 91.4452 91.4452 136.96 4.8 4.8

END

DEFINE MATERIAL START

ISOTROPIC STEEL

E 29000

POISSON 0.3

DENSITY 0.000283

ALPHA 6.5e-06

DAMP 0.03

G 11200

TYPE STEEL

STRENGTH RY 1.5 RT 1.2

END DEFINE MATERIAL

MEMBER PROPERTY AMERICAN

1 TABLE ST W12X72

3 TABLE ST W12X72

MEMBER PROPERTY

2 UPTABLE 1 SHS

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 FIXED

4 FIXED

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

MEMBER LOAD

2 UNI GY -2.25

LOAD 2 LOADTYPE None TITLE LOAD CASE 2

JOINT LOAD

2 FX 50 FZ 25

LOAD 3 LOADTYPE None TITLE LOAD CASE 3

MEMBER LOAD

2 CMOM GX 0.75

PERFORM ANALYSIS

PRINT ANALYSIS RESULTS

PARAMETER 1

CODE AISC UNIFIED 2005

SLF 0.8 MEMB 2

FYLD 50 ALL

FU 60 ALL

METHOD LRFD

STP 2 MEMB 2

TRACK 2 MEMB 2

CHECK CODE MEMB 2

PARAMETER 2

CODE AISC UNIFIED 2005

SLF 0.8 MEMB 2

FYLD 50 ALL

FU 60 ALL

METHOD ASD

STP 2 MEMB 2

TRACK 2 MEMB 2

CHECK CODE MEMB 2

FINISH

STAAD.Pro Output

PAGE NO. 1 **************************************************** * * * STAAD.Pro CONNECT Edition * * Version 22.12.00.*** * * Proprietary Program of * * Bentley Systems, Inc. * * Date= OCT 27, 2022 * * Time= 15:29:26 * * * * Licensed to: Bentley Systems Inc * **************************************************** 1. STAAD SPACE INPUT FILE: AISC 360-05 UPT Square Hollow Section.STD 2. START JOB INFORMATION 3. ENGINEER DATE 13-APR-21 4. END JOB INFORMATION 5. INPUT WIDTH 79 6. UNIT INCHES KIP 7. JOINT COORDINATES 8. 1 0 0 0; 2 0 60 0; 3 60 60 0; 4 60 0 0 9. MEMBER INCIDENCES 10. 1 1 2; 2 2 3; 3 3 4 11. START USER TABLE 12. TABLE 1 13. UNIT INCHES KIP 14. TUBE 15. SHS 16. 9.24 8 8 0.3 91.4452 91.4452 136.96 4.8 4.8 17. END 18. DEFINE MATERIAL START 19. ISOTROPIC STEEL 20. E 29000 21. POISSON 0.3 22. DENSITY 0.000283 23. ALPHA 6.5E-06 24. DAMP 0.03 25. G 11200 26. TYPE STEEL 27. STRENGTH RY 1.5 RT 1.2 28. END DEFINE MATERIAL 29. MEMBER PROPERTY AMERICAN 30. 1 TABLE ST W12X72 31. 3 TABLE ST W12X72 32. MEMBER PROPERTY 33. 2 UPTABLE 1 SHS 34. CONSTANTS 35. MATERIAL STEEL ALL 36. SUPPORTS 37. 1 FIXED 38. 4 FIXED STAAD SPACE -- PAGE NO. 2 39. LOAD 1 LOADTYPE NONE TITLE LOAD CASE 1 40. MEMBER LOAD 41. 2 UNI GY -2.25 42. LOAD 2 LOADTYPE NONE TITLE LOAD CASE 2 43. JOINT LOAD 44. 2 FX 50 FZ 25 45. LOAD 3 LOADTYPE NONE TITLE LOAD CASE 3 46. MEMBER LOAD 47. 2 CMOM GX 0.75 48. PERFORM ANALYSIS P R O B L E M S T A T I S T I C S ----------------------------------- NUMBER OF JOINTS 4 NUMBER OF MEMBERS 3 NUMBER OF PLATES 0 NUMBER OF SOLIDS 0 NUMBER OF SURFACES 0 NUMBER OF SUPPORTS 2 Using 64-bit analysis engine. SOLVER USED IS THE IN-CORE ADVANCED MATH SOLVER TOTAL PRIMARY LOAD CASES = 3, TOTAL DEGREES OF FREEDOM = 12 TOTAL LOAD COMBINATION CASES = 0 SO FAR. 49. PRINT ANALYSIS RESULTS ANALYSIS RESULTS STAAD SPACE -- PAGE NO. 3 JOINT DISPLACEMENT (INCH RADIANS) STRUCTURE TYPE = SPACE ------------------ JOINT LOAD X-TRANS Y-TRANS Z-TRANS X-ROTAN Y-ROTAN Z-ROTAN 1 1 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 2 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 3 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 2 1 0.00132 -0.00662 0.00000 0.00000 0.00000 -0.00085 2 0.09809 0.00107 0.28808 0.00654 0.00408 -0.00152 3 0.00000 0.00000 0.00012 0.00000 0.00000 0.00000 3 1 -0.00132 -0.00662 0.00000 0.00000 0.00000 0.00085 2 0.09263 -0.00107 0.04272 0.00141 0.00408 -0.00142 3 0.00000 0.00000 0.00012 0.00000 0.00000 0.00000 4 1 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 2 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 3 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000 STAAD SPACE -- PAGE NO. 4 SUPPORT REACTIONS -UNIT KIP INCH STRUCTURE TYPE = SPACE ----------------- JOINT LOAD FORCE-X FORCE-Y FORCE-Z MOM-X MOM-Y MOM Z 1 1 11.80 67.50 0.00 0.00 0.00 -108.35 2 -25.61 -10.88 -24.93 -1364.43 -2.23 1206.26 3 0.00 0.00 0.00 -0.38 0.00 0.00 4 1 -11.80 67.50 0.00 0.00 0.00 108.35 2 -24.39 10.88 -0.07 -135.57 -2.23 1141.12 3 0.00 0.00 0.00 -0.38 0.00 0.00 STAAD SPACE -- PAGE NO. 5 MEMBER END FORCES STRUCTURE TYPE = SPACE ----------------- ALL UNITS ARE -- KIP INCH (LOCAL ) MEMBER LOAD JT AXIAL SHEAR-Y SHEAR-Z TORSION MOM-Y MOM-Z 1 1 1 67.50 -11.80 0.00 0.00 0.00 -108.35 2 -67.50 11.80 0.00 0.00 0.00 -599.73 2 1 -10.88 25.61 -24.93 -2.23 1364.43 1206.26 2 10.88 -25.61 24.93 2.23 131.11 330.63 3 1 0.00 0.00 -0.00 -0.00 0.38 0.00 2 0.00 0.00 0.00 0.00 -0.38 0.00 2 1 2 11.80 67.50 0.00 0.00 0.00 599.73 3 -11.80 67.50 0.00 0.00 0.00 -599.73 2 2 24.39 -10.88 0.07 131.11 -2.23 -330.63 3 -24.39 10.88 -0.07 -131.11 -2.23 -321.98 3 2 0.00 0.00 0.00 -0.38 -0.00 0.00 3 0.00 0.00 -0.00 -0.38 0.00 0.00 3 1 3 67.50 11.80 0.00 0.00 0.00 599.73 4 -67.50 -11.80 0.00 0.00 0.00 108.35 2 3 10.88 24.39 0.07 -2.23 131.11 321.98 4 -10.88 -24.39 -0.07 2.23 -135.57 1141.12 3 3 0.00 0.00 -0.00 -0.00 0.38 0.00 4 0.00 0.00 0.00 0.00 -0.38 0.00 ************** END OF LATEST ANALYSIS RESULT ************** 50. PARAMETER 1 51. CODE AISC UNIFIED 2005 52. SLF 0.8 MEMB 2 53. FYLD 50 ALL 54. FU 60 ALL 55. METHOD LRFD 56. STP 2 MEMB 2 57. TRACK 2 MEMB 2 58. CHECK CODE MEMB 2 STEEL DESIGN STAAD SPACE -- PAGE NO. 6 STAAD.PRO CODE CHECKING - (AISC-360-05-LRFD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) MEMBER TABLE RESULT/ CRITICAL COND/ RATIO/ LOADING/ FX MY MZ LOCATION ======================================================================= 2 ST SHS (UPT) PASS Sec. G1 0.521 1 11.80 C 0.00 599.73 0.00 |-----------------------------------------------------------------------| | SLENDERNESS | | Actual Slenderness Ratio : 19.072 L/C : 1 | | Allowable Slenderness Ratio : 200.000 LOC : 0.00 | |-----------------------------------------------------------------------| | STRENGTH CHECKS | | Critical L/C : 1 Ratio : 0.521(PASS) | | Loc : 0.00 Condition : Sec. G1 | |-----------------------------------------------------------------------| | DESIGN FORCES | | Fx: 1.180E+01(C ) Fy: 6.750E+01 Fz: 0.000E+00 | | Mx: 0.000E+00 My: 0.000E+00 Mz: 5.997E+02 | |-----------------------------------------------------------------------| | SECTION PROPERTIES (UNIT: INCH) | | Azz: 4.800E+00 Ayy: 4.800E+00 Cw: 0.000E+00 | | Szz: 2.286E+01 Syy: 2.286E+01 | | Izz: 9.145E+01 Iyy: 9.145E+01 Ix: 1.370E+02 | |-----------------------------------------------------------------------| | MATERIAL PROPERTIES | | Fyld: 50.000 Fu: 60.000 | |-----------------------------------------------------------------------| | Actual Member Length: 60.000 | | Design Parameters | | Kz: 1.00 Ky: 1.00 NSF: 1.00 SLF: 0.80 CSP: 12.00 | |-----------------------------------------------------------------------| | SECTION CLASS UNSTIFFENED / λ λp λr CASE | | STIFFENED | | Compression : Non-Slender 0.00 N/A 0.00 N/A | | Non-Slender 25.67 N/A 33.72 T.B4.1-12 | | Flexure : Compact 25.67 26.97 33.72 T.B4.1-12 | | Compact 25.67 58.28 137.27 T.B4.1-13 | STAAD SPACE -- PAGE NO. 7 STAAD.PRO CODE CHECKING - (AISC-360-05-LRFD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) |-----------------------------------------------------------------------| | CHECK FOR AXIAL TENSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Yield 0.00E+00 4.16E+02 0.000 Eq. D2-1 1 0.00 | | Rupture 0.00E+00 3.33E+02 0.000 Eq. D2-2 1 0.00 | |-----------------------------------------------------------------------| | CHECK FOR AXIAL COMPRESSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Maj Buck 2.44E+01 4.05E+02 0.060 Sec. E1 2 0.00 | | Min Buck 2.44E+01 4.05E+02 0.060 Eq. E3-1 2 0.00 | | Intermediate | | Results Eff Area KL/r Fcr Fe Pn | | Maj Buck 9.24E+00 19.07 4.87E+01 7.87E+02 4.50E+02 | | Min Buck 9.24E+00 19.07 4.87E+01 7.87E+02 4.50E+02 | |-----------------------------------------------------------------------| | CHECK FOR SHEAR | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Local-Z -7.44E-02 1.30E+02 0.001 Eq. G2-1 2 0.00 | | Local-Y 6.75E+01 1.30E+02 0.521 Eq. G2-1 1 0.00 | | Intermediate | | Results Aw Cv Kv h/tw Vn | | Local-Z 4.80E+00 1.00 5.00 25.67 1.44E+02 | | Local-Y 4.80E+00 1.00 5.00 25.67 1.44E+02 | |-----------------------------------------------------------------------| | CHECK FOR TORSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | 1.31E+02 9.58E+02 0.137 Eq. H3-1 2 0.00 | | Intermediate Fcr Tn | | 3.00E+01 1.06E+03 | |-----------------------------------------------------------------------| | CHECK FOR BENDING-YIELDING | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Major -6.00E+02 1.20E+03 0.499 Eq. F7-1 1 0.00 | | Minor -2.23E+00 1.20E+03 0.002 Eq. F7-1 2 0.00 | | Intermediate Mn My | | Major 1.33E+03 0.00E+00 | | Minor 1.33E+03 0.00E+00 | STAAD SPACE -- PAGE NO. 8 STAAD.PRO CODE CHECKING - (AISC-360-05-LRFD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) |-----------------------------------------------------------------------| | CHECK FOR FLEXURE TENS/COMP INTERACTION | | RATIO CRITERIA L/C LOC | | Flexure Comp 0.514 Eq. H1-1b 1 0.00 | | Flexure Tens 0.499 Eq. H1-1b 1 0.00 | | Intermediate Mcx Mrx Pc | | Mcy Mry Pr | | Flexure Comp 1.20E+03 -6.00E+02 4.05E+02 | | 1.20E+03 0.00E+00 1.18E+01 | | Flexure Tens 1.20E+03 -6.00E+02 3.33E+02 | | 1.20E+03 0.00E+00 0.00E+00 | |-----------------------------------------------------------------------| 59. PARAMETER 2 60. CODE AISC UNIFIED 2005 61. SLF 0.8 MEMB 2 62. FYLD 50 ALL 63. FU 60 ALL 64. METHOD ASD 65. STP 2 MEMB 2 66. TRACK 2 MEMB 2 67. CHECK CODE MEMB 2 STEEL DESIGN STAAD SPACE -- PAGE NO. 9 STAAD.PRO CODE CHECKING - ( AISC-360-05-ASD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) MEMBER TABLE RESULT/ CRITICAL COND/ RATIO/ LOADING/ FX MY MZ LOCATION ======================================================================= 2 ST SHS (UPT) PASS Sec. G1 0.783 1 11.80 C 0.00 599.73 0.00 |-----------------------------------------------------------------------| | SLENDERNESS | | Actual Slenderness Ratio : 19.072 L/C : 1 | | Allowable Slenderness Ratio : 200.000 LOC : 0.00 | |-----------------------------------------------------------------------| | STRENGTH CHECKS | | Critical L/C : 1 Ratio : 0.783(PASS) | | Loc : 0.00 Condition : Sec. G1 | |-----------------------------------------------------------------------| | DESIGN FORCES | | Fx: 1.180E+01(C ) Fy: 6.750E+01 Fz: 0.000E+00 | | Mx: 0.000E+00 My: 0.000E+00 Mz: 5.997E+02 | |-----------------------------------------------------------------------| | SECTION PROPERTIES (UNIT: INCH) | | Azz: 4.800E+00 Ayy: 4.800E+00 Cw: 0.000E+00 | | Szz: 2.286E+01 Syy: 2.286E+01 | | Izz: 9.145E+01 Iyy: 9.145E+01 Ix: 1.370E+02 | |-----------------------------------------------------------------------| | MATERIAL PROPERTIES | | Fyld: 50.000 Fu: 60.000 | |-----------------------------------------------------------------------| | Actual Member Length: 60.000 | | Design Parameters | | Kz: 1.00 Ky: 1.00 NSF: 1.00 SLF: 0.80 CSP: 12.00 | |-----------------------------------------------------------------------| | SECTION CLASS UNSTIFFENED / λ λp λr CASE | | STIFFENED | | Compression : Non-Slender 0.00 N/A 0.00 N/A | | Non-Slender 25.67 N/A 33.72 T.B4.1-12 | | Flexure : Compact 25.67 26.97 33.72 T.B4.1-12 | | Compact 25.67 58.28 137.27 T.B4.1-13 | STAAD SPACE -- PAGE NO. 10 STAAD.PRO CODE CHECKING - ( AISC-360-05-ASD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) |-----------------------------------------------------------------------| | CHECK FOR AXIAL TENSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Yield 0.00E+00 2.77E+02 0.000 Eq. D2-1 1 0.00 | | Rupture 0.00E+00 2.22E+02 0.000 Eq. D2-2 1 0.00 | |-----------------------------------------------------------------------| | CHECK FOR AXIAL COMPRESSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Maj Buck 2.44E+01 2.69E+02 0.091 Sec. E1 2 0.00 | | Min Buck 2.44E+01 2.69E+02 0.091 Eq. E3-1 2 0.00 | | Intermediate | | Results Eff Area KL/r Fcr Fe Pn | | Maj Buck 9.24E+00 19.07 4.87E+01 7.87E+02 4.50E+02 | | Min Buck 9.24E+00 19.07 4.87E+01 7.87E+02 4.50E+02 | |-----------------------------------------------------------------------| | CHECK FOR SHEAR | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Local-Z -7.44E-02 8.62E+01 0.001 Eq. G2-1 2 0.00 | | Local-Y 6.75E+01 8.62E+01 0.783 Eq. G2-1 1 0.00 | | Intermediate | | Results Aw Cv Kv h/tw Vn | | Local-Z 4.80E+00 1.00 5.00 25.67 1.44E+02 | | Local-Y 4.80E+00 1.00 5.00 25.67 1.44E+02 | |-----------------------------------------------------------------------| | CHECK FOR TORSION | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | 1.31E+02 6.37E+02 0.206 Eq. H3-1 2 0.00 | | Intermediate Fcr Tn | | 3.00E+01 1.06E+03 | |-----------------------------------------------------------------------| | CHECK FOR BENDING-YIELDING | | | | FORCE CAPACITY RATIO CRITERIA L/C LOC | | Major -6.00E+02 7.99E+02 0.750 Eq. F7-1 1 0.00 | | Minor -2.23E+00 7.99E+02 0.003 Eq. F7-1 2 0.00 | | Intermediate Mn My | | Major 1.33E+03 0.00E+00 | | Minor 1.33E+03 0.00E+00 | STAAD SPACE -- PAGE NO. 11 STAAD.PRO CODE CHECKING - ( AISC-360-05-ASD) v3.3a ******************************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) |-----------------------------------------------------------------------| | CHECK FOR FLEXURE TENS/COMP INTERACTION | | RATIO CRITERIA L/C LOC | | Flexure Comp 0.772 Eq. H1-1b 1 0.00 | | Flexure Tens 0.750 Eq. H1-1b 1 0.00 | | Intermediate Mcx Mrx Pc | | Mcy Mry Pr | | Flexure Comp 7.99E+02 3.31E+02 2.69E+02 | | 7.99E+02 -2.23E+00 2.44E+01 | | Flexure Tens 7.99E+02 3.31E+02 2.22E+02 | | 7.99E+02 -2.23E+00 0.00E+00 | |-----------------------------------------------------------------------| | CHECK FOR FLEXURE TENS/COMP TORSION SHEAR INTERACTION | | RATIO CRITERIA L/C LOC | | Flx Tor Comp Shr 0.618 Eq. H3-6 2 0.00 | | Flx Tor Tens Shr 0.527 Eq. H3-6 2 0.00 | | Intermediate Mcx / Mcy / Mrx / Mry / | | Vcx / Vcy / Vrx / Vry / | | Tc Tr Pc Pr | | Flx Tor Comp Shr 7.99E+02 7.99E+02 3.31E+02 -2.23E+00 | | 8.62E+01 8.62E+01 -7.44E-02 -1.09E+01 | | 6.37E+02 1.31E+02 2.69E+02 2.44E+01 | | Flx Tor Tens Shr 7.99E+02 7.99E+02 3.31E+02 -2.23E+00 | | 8.62E+01 8.62E+01 -7.44E-02 -1.09E+01 | | 6.37E+02 1.31E+02 2.22E+02 0.00E+00 | |-----------------------------------------------------------------------| 68. FINISH STAAD SPACE -- PAGE NO. 12 *********** END OF THE STAAD.Pro RUN *********** **** DATE= OCT 27,2022 TIME= 15:29:27 **** ************************************************************ * For technical assistance on STAAD.Pro, please visit * * http://www.bentley.com/en/support/ * * * * Details about additional assistance from * * Bentley and Partners can be found at program menu * * Help->Technical Support * * * * Copyright (c) Bentley Systems, Inc. * * http://www.bentley.com * ************************************************************