General Information - Group Structure

ProStructures manages a four level group structure which clearly extends the possibilities of logical or constructive structuring. This structure is completely depicted in the DetailCenter and can be detailed with its own detail styles to workshop plans on each level separately.

Single Parts

These are the real component parts from which the next higher levels can be built. Depending on the selected grouping, these individual single parts then turn into main parts or add on parts or assembling parts.

Subordinate Groups (Subgroups)

Subgroups functionally correspond to the standard component part groups described below. However, they can be applied logically as independent subordinate structures in the higher structures.

For example, you can declare assemblies on stock as subgroups from which a separate workshop drawing won’t be required any more.

Groups

Each standard component part group, sometimes called main group, too, consists of a so-called main part and several subparts (add-on parts) – the main part defines the alignment of the different views on this component part group. In addition, each group can have subgroups.

Conventionally, the component part group is a group of component parts which are inseparably connected to each other (e.g., by welding).

Assemblies

This is the highest structure because it can be built from any single parts, subgroups and component part groups (which can contain subgroups themselves). An individual object determines the alignment of the different views on the assembly so that they can be independent of any component parts involved.

Assemblies often are any already mounted part constructions.

Use of Group Structure

In principle, there are nearly no limits for you how to group the component parts because the examples for application only represent few of the great number of possibilities. It is up to you whether you want to apply grouping according to construction for the order and the parts list or whether you only carry out a logical grouping for later 2D-drawings.

Within the DetailCenter, you find a hierarchic tree structure of grouping and you can filter and sort the display according to the different planes. Each structure and subordinate structure can be detailed as separate detail and inserted in the 2D-drawing.

The following example shows the practical use of group structure at detailing:

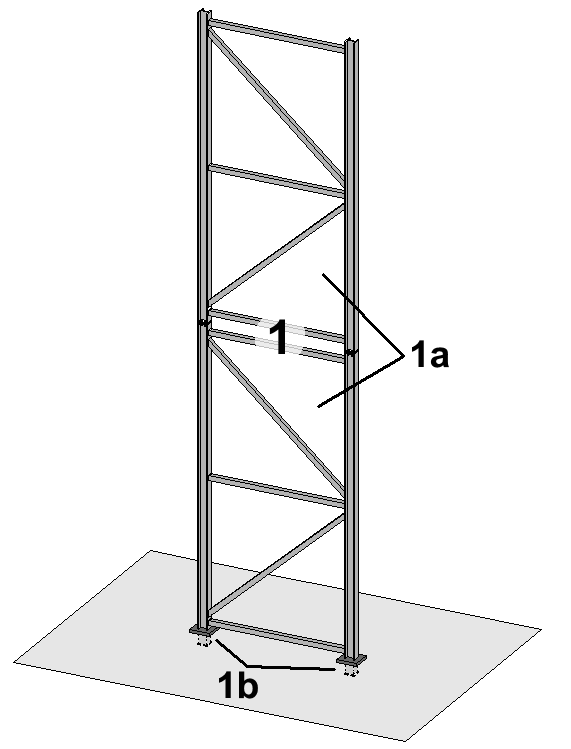

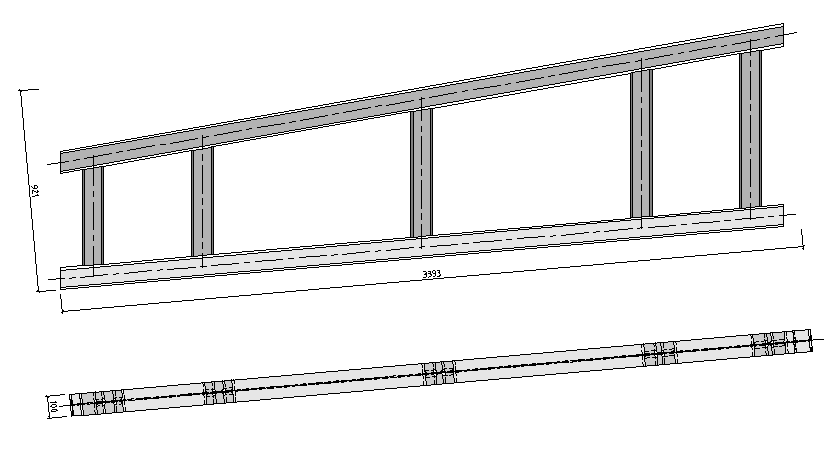

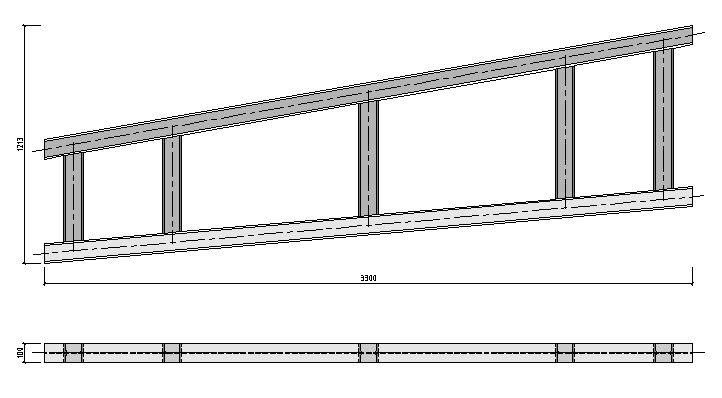

A column of a storage rack builds an assembly (1) of two component part groups (1a) which are bolted with each other. The lower of the two groups contains two welded base points which here however are assigned to the group as subgroups (1b).

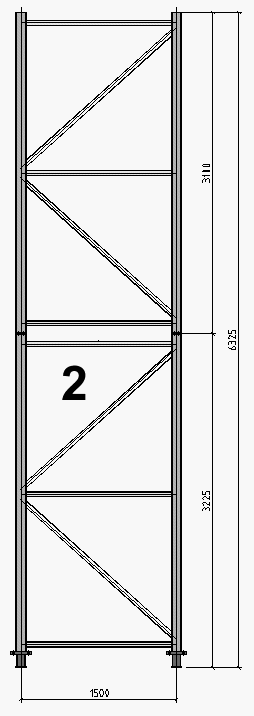

The detail drawing of the assembly (2) is showing the column of the storage rack standing and only with the main dimensions as a kind of total overview of the construction.

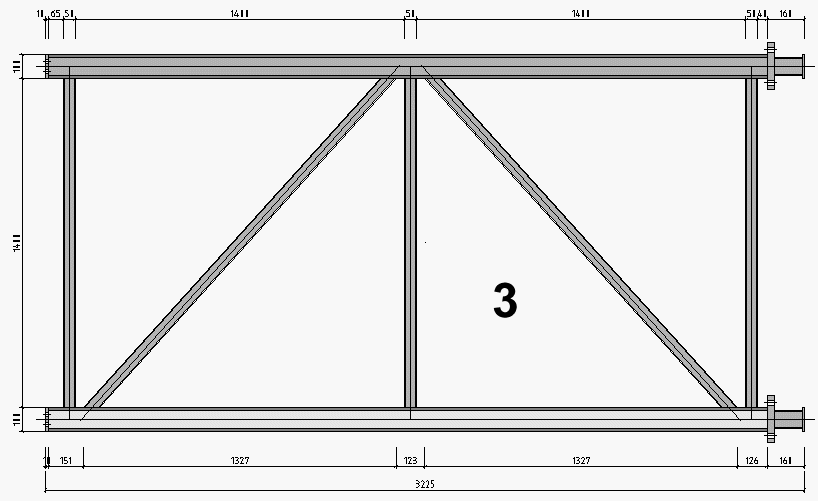

The detail of the component part group (3) now displays the position of the add-on parts in the component part group. The two base points are not dimensioned in a more detailed way, but they appear only as complete part.

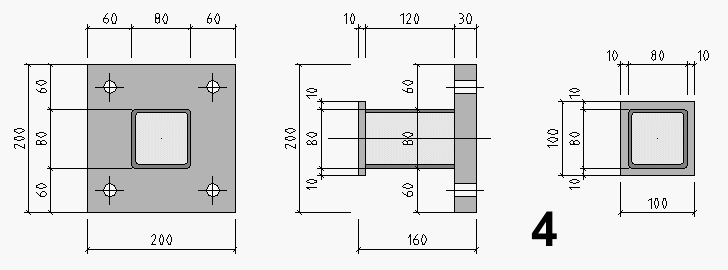

The base points can be inserted into the drawing as separate detail of the subgroup (4) with detailed mounting dimensions. In case of stock items this could of course be omitted.

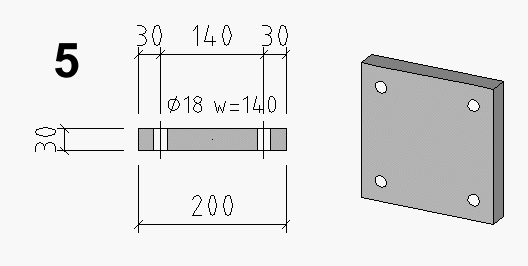

When the base point is manufactured together with the remaining group, you require perhaps single parts details (5) of the base plates which again can have a completely different detailing style.

Advantages of Assemblies

The use of assemblies may also be useful in situations where normally you would use only groups. As groups always determine the alignment of the views as well as the direction of dimensioning according to their main part, you often get a very unfavorable combination for certain oblique constructions.

In contrast, a superior assembly permits free selection of alignment and thus also of dimensioning. In addition, you can of course also dimension the group in main part direction in this drawing.

For more detailed information on dimensioning of complex group structures, please refer to the chapter Detailing Style of this manual.