Pipeline Spacing

The actual placement of a pipe segment depends on several variables. For example, pipe diameter, commodity, insulation type and thickness, as well as previously routed pipes all impact the placement of the current pipe segment being routed.

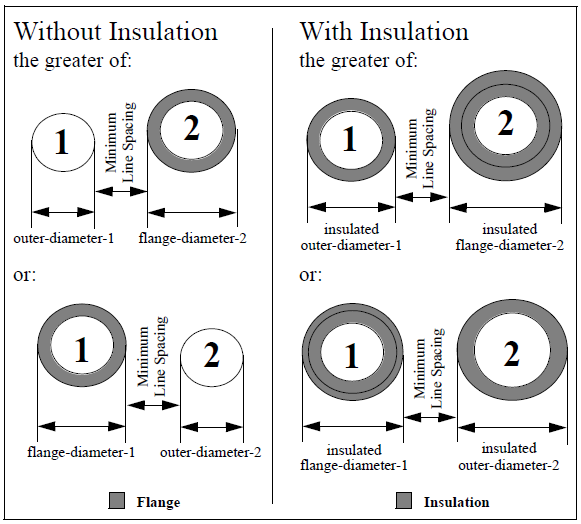

All pipelines have two basic spacing rules: centerline spacing and bottom-of-pipe offset.

Centerline Spacing

- (insulated-outer-diameter-1 + insulated-flange-diameter-2) / 2.0, or

- (insulated-flange-diameter-1 + insulated-outer-diameter-2) / 2.0

By default, AutoRouter only insulates flanges with cold insulation; however, you can add or change flange insulation in the Pipeline Editor dialog.

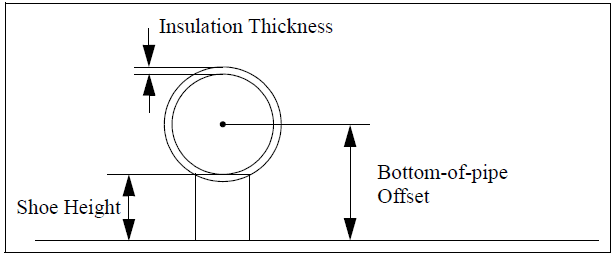

Bottom of Pipe Offset

- First, you can define an insulation thickness in the Pipeline List when defining a pipeline. That thickness will be used in conjunction with the commodity code to find an offset value from Insulation project variables.

- Second, a series of data table look ups will derive an offset.

- And third, the Default Insulation Thickness value defined in the project setup will be used if an insulation code has been provided but not a value for the thickness; in turn, that default thickness will be used to calculate the bottom-of-pipe offset.

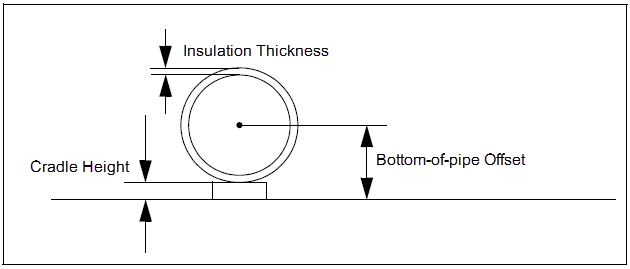

If the insulation type is:

if diameter > Hot (default) Pipe Shoe Minimum Diameter then if insulation thickness ≥ Hot (default) Pipe Shoe Threshold then offset = (0.5 * outer diameter) + Hot (default) Large Shoe Height else offset = (0.5 * outer diameter) + Hot (default) Small Shoe Height else offset = (0.5 * outer diameter) + insulation thicknessCOLD

offset = insulation thickness + cradle thickness (cradle thickness is from the cradle-dimensions data table)

ACOUSTIC

If insulation thickness is ≥ Acoustic Pipe Insulation Shoe Threshold then, offset = Acoustic Large Shoe Height. else, the offset = Acoustic Small Shoe Height.Other Type

offset = insulation thickness.Un-defined Type

If you define the insulation code as something other than those in the insulation-properties data table, the bottom-of-pipe offset will be determined in the same way as HOT insulation.