A thick cylindrical plate supported along 2 radial edges. Find the radial displacement, radial stress, tangential stress and longitudinal stress at inner surface due to a unit pressure applied at the inner surface.

Reference

MacNeal, R.H. and Harder, R.C., A Proposed Standard Set of Problems to Test Finite Element Accuracy, Finite Element in Analysis and Design 1, 1985.

Problem

Loading is unit pressure at inner radius

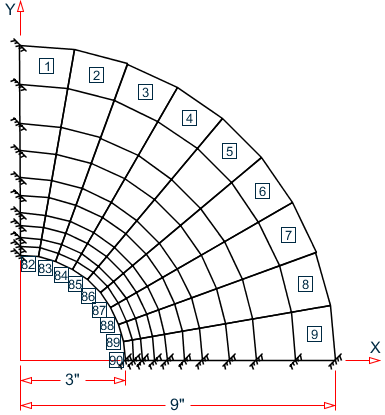

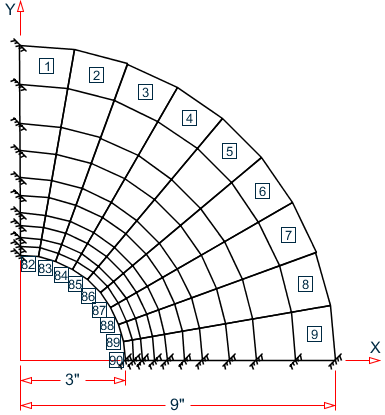

Semi-circular plate finite element model

Comparison

Table 1. Comparison of results

| Result Type |

Theory |

STAAD.Pro

|

Difference |

| Radial deflection (10-3 in) |

4.582 |

4.650a

|

1.5% |

| Radial stress (psi) |

-1.00 |

-0.95b

|

5.0% |

| Tangential stress (psi) |

1.25 |

1.26b

|

0.8% |

| Longitudinal stress (psi) |

0.075 |

0.080 |

7.0% |

- Radial displacements are measured along FY at node 102 and FX at node 101.

- On element 82, at node 102, SX is tangential stress, SY is radial stress.

STAAD Output

JOINT DISPLACEMENT (INCH RADIANS) STRUCTURE TYPE = SPACE

------------------

JOINT LOAD X-TRANS Y-TRANS Z-TRANS X-ROTAN Y-ROTAN Z-ROTAN

101 2 0.00465 0.00000 0.00000 0.00000 0.00000 0.00000

102 2 0.00000 0.00465 0.00000 0.00000 0.00000 0.00000

107 2 0.00357 0.00299 0.00000 0.00000 0.00000 0.00000

************** END OF LATEST ANALYSIS RESULT **************

97. LOAD LIST 1

98. PRINT ELEMENT JOINT STRESSES LIST 82 83 89 90

ELEMENT JOINT STRESSES LIST

:A THICK WALLED CYLINDER PLATE SUPPORTED ALONG 2 RADIAL -- PAGE NO. 5

ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH

----------------

STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH

ELEMENT LOAD SQX SQY MX MY MXY

VONT VONB SX SY SXY

TRESCAT TRESCAB

82 1 0.00 0.00 0.00 0.00 0.00

1.81 1.81 1.17 -0.91 0.00

2.08 2.08

TOP : SMAX= 1.17 SMIN= -0.91 TMAX= 1.04 ANGLE= 0.0

BOTT: SMAX= 1.17 SMIN= -0.91 TMAX= 1.04 ANGLE= 0.0

JOINT 0.00 0.00 0.00 0.00 0.00

92 1.69 1.69 1.07 -0.88 -0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

JOINT 0.00 0.00 0.00 0.00 0.00

93 1.69 1.69 1.07 -0.88 0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

JOINT 0.00 0.00 0.00 0.00 0.00

103 1.93 1.93 1.26 -0.95 0.08

TOP : SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= 2.1

BOTT: SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= 2.1

JOINT 0.00 0.00 0.00 0.00 0.00

102 1.93 1.93 1.26 -0.95 -0.08

TOP : SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= -2.0

BOTT: SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= -2.0

83 1 0.00 0.00 0.00 0.00 0.00

1.81 1.81 1.17 -0.92 -0.00

2.08 2.08

TOP : SMAX= 1.17 SMIN= -0.92 TMAX= 1.04 ANGLE= -0.0

BOTT: SMAX= 1.17 SMIN= -0.92 TMAX= 1.04 ANGLE= -0.0

JOINT 0.00 0.00 0.00 0.00 0.00

93 1.69 1.69 1.07 -0.88 -0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

JOINT 0.00 0.00 0.00 0.00 0.00

94 1.69 1.69 1.06 -0.88 0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

JOINT 0.00 0.00 0.00 0.00 0.00

104 1.93 1.93 1.26 -0.95 0.08

TOP : SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= 2.1

BOTT: SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= 2.1

JOINT 0.00 0.00 0.00 0.00 0.00

103 1.93 1.93 1.26 -0.95 -0.08

TOP : SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= -2.1

BOTT: SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= -2.1

89 1 0.00 0.00 0.00 0.00 0.00

1.81 1.81 1.17 -0.92 0.00

2.08 2.08

TOP : SMAX= 1.17 SMIN= -0.92 TMAX= 1.04 ANGLE= 0.0

BOTT: SMAX= 1.17 SMIN= -0.92 TMAX= 1.04 ANGLE= 0.0

:A THICK WALLED CYLINDER PLATE SUPPORTED ALONG 2 RADIAL -- PAGE NO. 6

ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH

----------------

STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH

ELEMENT LOAD SQX SQY MX MY MXY

VONT VONB SX SY SXY

TRESCAT TRESCAB

JOINT 0.00 0.00 0.00 0.00 0.00

99 1.69 1.69 1.06 -0.88 -0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

JOINT 0.00 0.00 0.00 0.00 0.00

100 1.69 1.69 1.07 -0.88 0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

JOINT 0.00 0.00 0.00 0.00 0.00

110 1.93 1.93 1.26 -0.95 0.08

TOP : SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= 2.1

BOTT: SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= 2.1

JOINT 0.00 0.00 0.00 0.00 0.00

109 1.93 1.93 1.26 -0.95 -0.08

TOP : SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= -2.1

BOTT: SMAX= 1.26 SMIN= -0.96 TMAX= 1.11 ANGLE= -2.1

90 1 0.00 0.00 0.00 0.00 0.00

1.81 1.81 1.17 -0.91 -0.00

2.08 2.08

TOP : SMAX= 1.17 SMIN= -0.91 TMAX= 1.04 ANGLE= -0.0

BOTT: SMAX= 1.17 SMIN= -0.91 TMAX= 1.04 ANGLE= -0.0

JOINT 0.00 0.00 0.00 0.00 0.00

100 1.69 1.69 1.07 -0.88 -0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= -2.3

JOINT 0.00 0.00 0.00 0.00 0.00

91 1.69 1.69 1.07 -0.88 0.08

TOP : SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

BOTT: SMAX= 1.07 SMIN= -0.88 TMAX= 0.98 ANGLE= 2.3

JOINT 0.00 0.00 0.00 0.00 0.00

101 1.93 1.93 1.26 -0.95 0.08

TOP : SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= 2.0

BOTT: SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= 2.0

JOINT 0.00 0.00 0.00 0.00 0.00

110 1.93 1.93 1.26 -0.95 -0.08

TOP : SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= -2.1

BOTT: SMAX= 1.26 SMIN= -0.95 TMAX= 1.11 ANGLE= -2.1

:A THICK WALLED CYLINDER PLATE SUPPORTED ALONG 2 RADIAL -- PAGE NO. 7

**** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES ****

MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM

PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA

STRESS STRESS STRESS STRESS STRESS

1.263807E+00 -9.557953E-01 1.109365E+00 1.807750E+00 2.082330E+00

PLATE NO. 82 83 82 89 89

CASE NO. 1 1 1 1 1