V. 2D Tapered Beam In-Plane Stress

To find element stress due to joint load at the fixed end of a tapered plate with one end fixed.

Reference

Crandall, S.H., & Dahl, N.C., An Introduction to the Mechanics of Solids, McGraw – Hill, Inc., 1959.

Problem

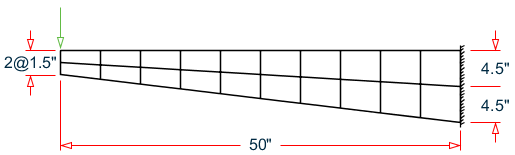

The tapered plate structure is loaded at the free end. Calculate the maximum stress at the midspan.

| E = 30,000.0 ksi |

| Thickness = 2 in |

| Poisson’s ratio = 0.2 |

| P = 4 kips |

Model

Comparison

The STAAD.Pro result is taken as average of stress in elements 9 and 11 at node 16 = 0.5(8,333.35 + 8,359.62) = 8,346.5.

| Result Type | Theory | STAAD.Pro | Difference |

|---|---|---|---|

| Maximum stress at the center (psi) | 8,333 | 8,346.5 | 0.2% |

STAAD Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\04 Plates Shells\2D Tapered Beam In-Plane Stress.STD is typically installed with the program.

STAAD SPACE :A TAPERED BEAM WITH PLATE ELEMENTS

START JOB INFORMATION

ENGINEER DATE 14-Sep-18

END JOB INFORMATION

*

* REFERENCE: CRANDALL, S. H., AND DAHL, N.C., "AN INTRODUCTION TO THE

* MECHANICS OF SOLIDS," MCGRAW-HILL BOOK CO., INC.,

* NEW YORK, 1978

*

INPUT WIDTH 79

UNIT INCHES POUND

JOINT COORDINATES

1 50 0 0; 2 50 -4.5 0; 3 50 -9 0; 4 45 0 0; 5 45 -4.2 0; 6 45 -8.4 0; 7 40 0 0;

8 40 -3.9 0; 9 40 -7.8 0; 10 35 0 0; 11 35 -3.6 0; 12 35 -7.2 0; 13 30 0 0;

14 30 -3.3 0; 15 30 -6.6 0; 16 25 0 0; 17 25 -3 0; 18 25 -6 0; 19 20 0 0;

20 20 -2.7 0; 21 20 -5.4 0; 22 15 0 0; 23 15 -2.4 0; 24 15 -4.8 0; 25 10 0 0;

26 10 -2.1 0; 27 10 -4.2 0; 28 5 0 0; 29 5 -1.8 0; 30 5 -3.6 0; 31 0 0 0;

32 0 -1.5 0; 33 0 -3 0;

ELEMENT INCIDENCES SHELL

1 4 5 2 1; 2 5 6 3 2; 3 7 8 5 4; 4 8 9 6 5; 5 10 11 8 7; 6 11 12 9 8;

7 13 14 11 10; 8 14 15 12 11; 9 16 17 14 13; 10 17 18 15 14; 11 19 20 17 16;

12 20 21 18 17; 13 22 23 20 19; 14 23 24 21 20; 15 25 26 23 22; 16 26 27 24 23;

17 28 29 26 25; 18 29 30 27 26; 19 31 32 29 28; 20 32 33 30 29;

ELEMENT PROPERTY

1 TO 20 THICKNESS 2

DEFINE MATERIAL START

ISOTROPIC MATERIAL1

E 3e+07

POISSON 0.2

END DEFINE MATERIAL

CONSTANTS

MATERIAL MATERIAL1 ALL

SUPPORTS

1 TO 3 FIXED

LOAD 1 POINT LOAD

JOINT LOAD

31 FY -4000

PERFORM ANALYSIS

PRINT ELEMENT JOINT STRESSES LIST 9 11

FINISH

STAAD Output

ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH ---------------- STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH ELEMENT LOAD SQX SQY MX MY MXY VONT VONB SX SY SXY TRESCAT TRESCAB 9 1 0.00 0.00 0.00 0.00 0.00 4157.59 4157.59 -4.32 4153.58 -71.59 4160.36 4160.36 TOP : SMAX= 4154.81 SMIN= -5.55 TMAX= 2080.18 ANGLE=-89.0 BOTT: SMAX= 4154.81 SMIN= -5.55 TMAX= 2080.18 ANGLE=-89.0 JOINT 0.00 0.00 0.00 0.00 0.00 16 8372.99 8372.99 -78.55 8333.17 38.19 TOP : SMAX= 8333.35 SMIN= -78.72 TMAX= 4206.03 ANGLE= 89.7 BOTT: SMAX= 8333.35 SMIN= -78.72 TMAX= 4206.03 ANGLE= 89.7 JOINT 0.00 0.00 0.00 0.00 0.00 17 343.34 343.34 42.49 3.59 -196.82 TOP : SMAX= 220.82 SMIN= -174.74 TMAX= 197.78 ANGLE=-42.2 BOTT: SMAX= 220.82 SMIN= -174.74 TMAX= 197.78 ANGLE=-42.2 JOINT 0.00 0.00 0.00 0.00 0.00 14 295.01 295.01 -107.35 -73.48 -161.24 TOP : SMAX= 71.72 SMIN= -252.54 TMAX= 162.13 ANGLE=-48.0 BOTT: SMAX= 71.72 SMIN= -252.54 TMAX= 162.13 ANGLE=-48.0 JOINT 0.00 0.00 0.00 0.00 0.00 13 8295.66 8295.66 93.65 8341.38 62.12 TOP : SMAX= 8341.85 SMIN= 93.18 TMAX= 4124.34 ANGLE= 89.6 BOTT: SMAX= 8341.85 SMIN= 93.18 TMAX= 4124.34 ANGLE= 89.6 11 1 0.00 0.00 0.00 0.00 0.00 4155.63 4155.63 -4.64 4149.10 -107.91 4159.35 4159.35 TOP : SMAX= 4151.91 SMIN= -7.44 TMAX= 2079.67 ANGLE=-88.5 BOTT: SMAX= 4151.91 SMIN= -7.44 TMAX= 2079.67 ANGLE=-88.5 JOINT 0.00 0.00 0.00 0.00 0.00 19 8323.84 8323.84 -72.93 8286.88 37.52 TOP : SMAX= 8287.05 SMIN= -73.10 TMAX= 4180.08 ANGLE= 89.7 BOTT: SMAX= 8287.05 SMIN= -73.10 TMAX= 4180.08 ANGLE= 89.7 JOINT 0.00 0.00 0.00 0.00 0.00 20 410.28 410.28 69.05 -21.19 -232.13 TOP : SMAX= 260.40 SMIN= -212.54 TMAX= 236.47 ANGLE=-39.5 BOTT: SMAX= 260.40 SMIN= -212.54 TMAX= 236.47 ANGLE=-39.5 JOINT 0.00 0.00 0.00 0.00 0.00 17 377.42 377.42 -132.29 -39.10 -207.04 TOP : SMAX= 126.52 SMIN= -297.91 TMAX= 212.21 ANGLE=-51.3 BOTT: SMAX= 126.52 SMIN= -297.91 TMAX= 212.21 ANGLE=-51.3 JOINT 0.00 0.00 0.00 0.00 0.00 16 8319.08 8319.08 82.05 8359.26 54.91 TOP : SMAX= 8359.62 SMIN= 81.68 TMAX= 4138.97 ANGLE= 89.6 BOTT: SMAX= 8359.62 SMIN= 81.68 TMAX= 4138.97 ANGLE= 89.6 :A TAPERED BEAM WITH PLATE ELEMENTS -- PAGE NO. 4 **** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES **** MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA STRESS STRESS STRESS STRESS STRESS 8.359622E+03 -2.979081E+02 4.206035E+03 4.157588E+03 4.160359E+03 PLATE NO. 11 11 9 9 9 CASE NO. 1 1 1 1 1