To find the bending moment due to thermal load through the thickness of a square plate.

Reference

Timoshenko, S., Strength of Materials, D. Van Nostrand Co., 3rd Edition,1956.

Problem

Temperature varies 100°F linearly through the thickness of a square plate that is fixed on the edges. Calculate the bending moment on the edges and the maximum bending stress.

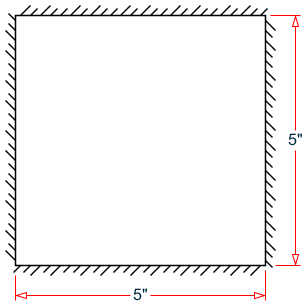

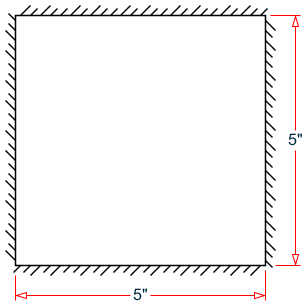

Model

Comparison

Table 1. Comparison of results

| Result Type |

Theory |

STAAD.Pro

|

Difference |

| Moment (in·lb/in) |

625.0 |

625.0 |

none |

| Maximum stress (psi) |

15,000 |

15,000 |

none |

STAAD Output

ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH

----------------

STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH

ELEMENT LOAD SQX SQY MX MY MXY

VONT VONB SX SY SXY

TRESCAT TRESCAB

1 1 -0.00 -0.00 -625.00 -625.00 0.00

15000.00 15000.00 0.00 0.00 0.00

15000.00 15000.00

TOP : SMAX= -15000.00 SMIN= -15000.00 TMAX= 0.00 ANGLE= 90.0

BOTT: SMAX= 15000.00 SMIN= 15000.00 TMAX= 0.00 ANGLE= 90.0

JOINT -0.00 -0.00 -625.00 -625.00 0.00

1 15000.00 15000.00 0.00 0.00 0.00

TOP : SMAX= -15000.00 SMIN= -15000.00 TMAX= 0.00 ANGLE= 90.0

BOTT: SMAX= 15000.00 SMIN= 15000.00 TMAX= 0.00 ANGLE= 90.0

JOINT -0.00 -0.00 -625.00 -625.00 0.00

2 15000.00 15000.00 0.00 0.00 0.00

TOP : SMAX= -15000.00 SMIN= -15000.00 TMAX= 0.00 ANGLE= 90.0

BOTT: SMAX= 15000.00 SMIN= 15000.00 TMAX= 0.00 ANGLE= 90.0

JOINT -0.00 -0.00 -625.00 -625.00 -0.00

4 15000.00 15000.00 0.00 0.00 0.00

TOP : SMAX= -15000.00 SMIN= -15000.00 TMAX= 0.00 ANGLE= 90.0

BOTT: SMAX= 15000.00 SMIN= 15000.00 TMAX= 0.00 ANGLE= 90.0

JOINT -0.00 -0.00 -625.00 -625.00 0.00

3 15000.00 15000.00 0.00 0.00 0.00

TOP : SMAX= -15000.00 SMIN= -15000.00 TMAX= 0.00 ANGLE= 90.0

BOTT: SMAX= 15000.00 SMIN= 15000.00 TMAX= 0.00 ANGLE= 90.0

**** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES ****

MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM

PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA

STRESS STRESS STRESS STRESS STRESS

1.500000E+04 -1.500000E+04 1.011339E-03 1.500000E+04 1.500000E+04

PLATE NO. 1 1 1 1 1

CASE NO. 1 1 1 1 1