V. 2D Surface Displacements

To find the vertical deflection and bending moments due to an unit pressure in a rectangular plate simply supported along four edges.

References

Martin, H. C., Stiffness Matrix for a Triangular Sandwich Element in Bending, NASA Technical Report 32-1158, October, 1967.

Timoshenko, S., Strength of Materials, D. Van Nostrand Co., 3rd Edition,1956.

Salerno, V. L., and Goldberg, M. A., Effect of Shear Deformations on the Bending of Rectangular Plates, March 1960, Pages 54-58.

Problem

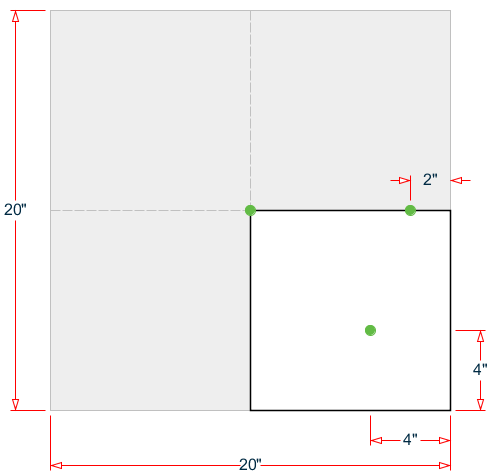

Find the vertical deflection at the points shown in the sketch and the bending stress at the center of a 20 in. square plate subjected to a uniform pressure of 1 ksi. Use a quarter of the plate assuming proper boundary conditions along the lines of symmetry.

| E = 10,000.0 ksi |

| Thickness = 5 in |

| Poisson’s ratio = 0.4 |

Comparison

| Result Type | Theory | STAAD.Pro | Difference | Comments | |

|---|---|---|---|---|---|

| Vertical deflections due to unit pressure, 10-3 in | δ1 | 6.826 | 6.864 | 0.6% | |

| δ9 | 2.322 | 2.343 | 0.9% | ||

| δ73 | 2.684 | 2.707 | 0.9% | ||

| Maximum bending stress due to unit pressure, σ, element 1 (psi) | 5,071 | 4,908 | 3.2% | The theoretical results from classical Plate theory was compared with the results from Finite Element model - hence the difference in results. | |

STAAD Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\04 Plates Shells\2D Surface Displacements.STD is typically installed with the program.

STAAD SPACE :A SIMPLY SUPPORTED PLATE WITH TRIANGULAR ELEMENTS

START JOB INFORMATION

ENGINEER DATE 14-Sep-18

END JOB INFORMATION

INPUT WIDTH 72

UNIT INCHES POUND

JOINT COORDINATES

1 0 0 0; 2 1 0 0; 3 2 0 0; 4 3 0 0; 5 4 0 0; 6 5 0 0; 7 6 0 0; 8 7 0 0;

9 8 0 0; 10 9 0 0; 11 10 0 0; 12 0 0 1; 13 1 0 1; 14 2 0 1; 15 3 0 1;

16 4 0 1; 17 5 0 1; 18 6 0 1; 19 7 0 1; 20 8 0 1; 21 9 0 1; 22 10 0 1;

23 0 0 2; 24 1 0 2; 25 2 0 2; 26 3 0 2; 27 4 0 2; 28 5 0 2; 29 6 0 2;

30 7 0 2; 31 8 0 2; 32 9 0 2; 33 10 0 2; 34 0 0 3; 35 1 0 3; 36 2 0 3;

37 3 0 3; 38 4 0 3; 39 5 0 3; 40 6 0 3; 41 7 0 3; 42 8 0 3; 43 9 0 3;

44 10 0 3; 45 0 0 4; 46 1 0 4; 47 2 0 4; 48 3 0 4; 49 4 0 4; 50 5 0 4;

51 6 0 4; 52 7 0 4; 53 8 0 4; 54 9 0 4; 55 10 0 4; 56 0 0 5; 57 1 0 5;

58 2 0 5; 59 3 0 5; 60 4 0 5; 61 5 0 5; 62 6 0 5; 63 7 0 5; 64 8 0 5;

65 9 0 5; 66 10 0 5; 67 0 0 6; 68 1 0 6; 69 2 0 6; 70 3 0 6; 71 4 0 6;

72 5 0 6; 73 6 0 6; 74 7 0 6; 75 8 0 6; 76 9 0 6; 77 10 0 6; 78 0 0 7;

79 1 0 7; 80 2 0 7; 81 3 0 7; 82 4 0 7; 83 5 0 7; 84 6 0 7; 85 7 0 7;

86 8 0 7; 87 9 0 7; 88 10 0 7; 89 0 0 8; 90 1 0 8; 91 2 0 8; 92 3 0 8;

93 4 0 8; 94 5 0 8; 95 6 0 8; 96 7 0 8; 97 8 0 8; 98 9 0 8; 99 10 0 8;

100 0 0 9; 101 1 0 9; 102 2 0 9; 103 3 0 9; 104 4 0 9; 105 5 0 9;

106 6 0 9; 107 7 0 9; 108 8 0 9; 109 9 0 9; 110 10 0 9; 111 0 0 10;

112 1 0 10; 113 2 0 10; 114 3 0 10; 115 4 0 10; 116 5 0 10; 117 6 0 10;

118 7 0 10; 119 8 0 10; 120 9 0 10; 121 10 0 10;

ELEMENT INCIDENCES SHELL

1 1 2 12; 2 2 3 13; 3 3 4 14; 4 4 5 15; 5 5 6 16; 6 6 7 17; 7 7 8 18;

8 8 9 19; 9 9 10 20; 10 10 11 21; 11 12 2 13; 12 13 3 14; 13 14 4 15;

14 15 5 16; 15 16 6 17; 16 17 7 18; 17 18 8 19; 18 19 9 20; 19 20 10 21;

20 21 11 22; 21 12 13 23; 22 13 14 24; 23 14 15 25; 24 15 16 26;

25 16 17 27; 26 17 18 28; 27 18 19 29; 28 19 20 30; 29 20 21 31;

30 21 22 32; 31 23 13 24; 32 24 14 25; 33 25 15 26; 34 26 16 27;

35 27 17 28; 36 28 18 29; 37 29 19 30; 38 30 20 31; 39 31 21 32;

40 32 22 33; 41 23 24 34; 42 24 25 35; 43 25 26 36; 44 26 27 37;

45 27 28 38; 46 28 29 39; 47 29 30 40; 48 30 31 41; 49 31 32 42;

50 32 33 43; 51 34 24 35; 52 35 25 36; 53 36 26 37; 54 37 27 38;

55 38 28 39; 56 39 29 40; 57 40 30 41; 58 41 31 42; 59 42 32 43;

60 43 33 44; 61 34 35 45; 62 35 36 46; 63 36 37 47; 64 37 38 48;

65 38 39 49; 66 39 40 50; 67 40 41 51; 68 41 42 52; 69 42 43 53;

70 43 44 54; 71 45 35 46; 72 46 36 47; 73 47 37 48; 74 48 38 49;

75 49 39 50; 76 50 40 51; 77 51 41 52; 78 52 42 53; 79 53 43 54;

80 54 44 55; 81 45 46 56; 82 46 47 57; 83 47 48 58; 84 48 49 59;

85 49 50 60; 86 50 51 61; 87 51 52 62; 88 52 53 63; 89 53 54 64;

90 54 55 65; 91 56 46 57; 92 57 47 58; 93 58 48 59; 94 59 49 60;

95 60 50 61; 96 61 51 62; 97 62 52 63; 98 63 53 64; 99 64 54 65;

100 65 55 66; 101 56 57 67; 102 57 58 68; 103 58 59 69; 104 59 60 70;

105 60 61 71; 106 61 62 72; 107 62 63 73; 108 63 64 74; 109 64 65 75;

110 65 66 76; 111 67 57 68; 112 68 58 69; 113 69 59 70; 114 70 60 71;

115 71 61 72; 116 72 62 73; 117 73 63 74; 118 74 64 75; 119 75 65 76;

120 76 66 77; 121 67 68 78; 122 68 69 79; 123 69 70 80; 124 70 71 81;

125 71 72 82; 126 72 73 83; 127 73 74 84; 128 74 75 85; 129 75 76 86;

130 76 77 87; 131 78 68 79; 132 79 69 80; 133 80 70 81; 134 81 71 82;

135 82 72 83; 136 83 73 84; 137 84 74 85; 138 85 75 86; 139 86 76 87;

140 87 77 88; 141 78 79 89; 142 79 80 90; 143 80 81 91; 144 81 82 92;

145 82 83 93; 146 83 84 94; 147 84 85 95; 148 85 86 96; 149 86 87 97;

150 87 88 98; 151 89 79 90; 152 90 80 91; 153 91 81 92; 154 92 82 93;

155 93 83 94; 156 94 84 95; 157 95 85 96; 158 96 86 97; 159 97 87 98;

160 98 88 99; 161 89 90 100; 162 90 91 101; 163 91 92 102;

164 92 93 103; 165 93 94 104; 166 94 95 105; 167 95 96 106;

168 96 97 107; 169 97 98 108; 170 98 99 109; 171 100 90 101;

172 101 91 102; 173 102 92 103; 174 103 93 104; 175 104 94 105;

176 105 95 106; 177 106 96 107; 178 107 97 108; 179 108 98 109;

180 109 99 110; 181 100 101 111; 182 101 102 112; 183 102 103 113;

184 103 104 114; 185 104 105 115; 186 105 106 116; 187 106 107 117;

188 107 108 118; 189 108 109 119; 190 109 110 120; 191 111 101 112;

192 112 102 113; 193 113 103 114; 194 114 104 115; 195 115 105 116;

196 116 106 117; 197 117 107 118; 198 118 108 119; 199 119 109 120;

200 120 110 121;

ELEMENT PROPERTY

1 TO 200 THICKNESS 5

DEFINE MATERIAL START

ISOTROPIC MATERIAL1

E 1e+07

POISSON 0.4

END DEFINE MATERIAL

CONSTANTS

MATERIAL MATERIAL1 ALL

SUPPORTS

1 FIXED BUT FY

2 TO 10 FIXED BUT FX FY MZ

12 23 34 45 56 67 78 89 100 FIXED BUT FY FZ MX

11 22 33 44 55 66 77 88 99 110 FIXED BUT MZ

111 TO 120 FIXED BUT MX

121 FIXED

LOAD 1 UNIFORM PRESSURE

ELEMENT LOAD

1 TO 200 PR -1000

PERFORM ANALYSIS

PRINT JOINT DISPLACEMENTS LIST 1 9 73

PRINT ELEMENT STRESSES LIST 1

FINISH

STAAD Output

JOINT DISPLACEMENT (INCH RADIANS) STRUCTURE TYPE = SPACE ------------------ JOINT LOAD X-TRANS Y-TRANS Z-TRANS X-ROTAN Y-ROTAN Z-ROTAN 1 1 0.00000 0.00686 0.00000 0.00000 0.00000 0.00000 9 1 0.00000 0.00234 0.00000 0.00000 0.00000 -0.00080 73 1 0.00000 0.00271 0.00000 0.00040 0.00000 -0.00040 ************** END OF LATEST ANALYSIS RESULT ************** 90. PRINT ELEMENT STRESSES LIST 1 ELEMENT STRESSES LIST 1 :A SIMPLY SUPPORTED PLATE WITH TRIANGULAR ELEMENTS -- PAGE NO. 5 ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH ---------------- STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH ELEMENT LOAD SQX SQY MX MY MXY VONT VONB SX SY SXY TRESCAT TRESCAB 1 1 33.33 33.33 -20451.07 -20451.07 0.00 4908.26 4908.26 0.00 0.00 0.00 4908.26 4908.26 TOP : SMAX= -4908.26 SMIN= -4908.26 TMAX= 0.00 ANGLE= 90.0 BOTT: SMAX= 4908.26 SMIN= 4908.26 TMAX= 0.00 ANGLE= 90.0 **** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES **** MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA STRESS STRESS STRESS STRESS STRESS 4.908257E+03 -4.908257E+03 0.000000E+00 4.908257E+03 4.908257E+03 PLATE NO. 1 1 1 1 1 CASE NO. 1 1 1 1 1