V. IS 800 2007 LSD - I Section with Cover Plate

Verify the design of an I section with cover plates subject to axial force and biaxial bending per the IS 800:2007 limit state method.

BIS. IS 800: General Construction in Steel - Code of Practice. 2007. Bureau of Indian Standards. New Delhi.

BIS. IS 808: Dimensions for Hot Rolled Steel Beam, Column, Channel and Angle Sections. 1989. Bureau of Indian Standards. New Delhi.

Details

- a 55.98 kN·m moment about the major axis

- a 10 kN·m moment about the minor axis

- a 23.984 kN compressive force

- a 2 kN shear force along the major axis

- a 1.2 kN shear force along the minor axis

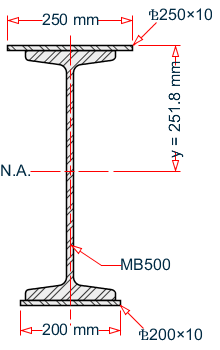

The section used is an ISMB500 with a 250 mm × 10 mm top cover plate and a 200 mm × 10 mm bottom cover plate. The section is braced to prevent lateral-torsional buckling. The steel has a yield strength of 250 MPa, an ultimate tensile strength of 420 MPa, and a modulus of elasticity of 205×(10)3 MPa.

Validation

Section Properties

Overall depth of the whole section, h = D + tpl1 + tpl2 = 500 + 10 + 10 = 520 mm

Depth of web of IS MB500, dw = D - 2×tf = 500 - 2 × 17.2 = 465.6 mm

Cross-section area of top cover plate, Atop = 25 cm × 1 cm = 25 cm2

Cross-section area of bottom cover plate, Abottom = 20 cm × 1 cm = 20 cm2

Cross-section area, Ax = 111 cm2 + 25 cm2 + 20 cm2 = 156 cm2

Distance of CG from top of overall section:

Overall moment of inertia about the major axis:

Overall moment of inertia about the minor axis (section is symmetric about this axis):

Radius of gyration about the major axis,

Radius of gyration about the minor axis,

Elastic section modulus about the major axis,

Elastic section modulus about the minor axis,

Distance to equal area axis from top,

Plastic section modulus about the major axis,

Plastic section modulus about the minor axis,

Constants

- γm0 = 1.1

- γm1 = 1.25

Section Classification

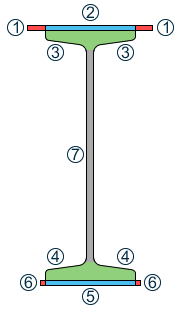

Section classification of different portions of the section must be checked separately. Checking is performed per Table 2 of IS 800:2007 as indicated in the following figure:

- Outstanding element of top cover plate: hence, plastic.

- Internal element of top cover plate: hence, plastic.

- Internal element of top flange hence, plastic.

- Internal element of bottom flange hence, plastic.

- Internal element of bottom cover plate hence, plastic.

- Outstanding element of bottom cover plate hence, plastic.

- Web of ISMB section hence, plastic.

Overall classification of the section is based on the most critical class among the different classes identified above. Here, the overall section is classified as "plastic".

Since tf = 17.2 mm < 40 mm

Hence, from Table 10, as per the requirements of welded I section, the buckling class about major axis buckling is "b" and the same about minor axis buckling is "c".

Check Slenderness Ratio

ky = kz = 1

The maximum allowable slenderness ratio is 180.

Slenderness ratio about the major axis, kzL / rz = 1.0 × 500 / 21.8 = 22.9 < 180

Slenderness ratio about the minor axis, kyL / ry = 1.0 × 500 / 4.63 = 108.0 < 180

So the slenderness is within the limit.

Axial Tension Capacity

Check for yielding of gross section:

Tdg = Ag × fy / γm0 = 3,545 kN

Check for rupture of critical section:

α = 0.8

Tdn = α × Anet × fu / γm1 = 4,193 kN

Block shear areas are not specified and therefore not checked.

No tension in the member, so critical ratio is 0.

Check Axial Compression

Axial compression capacity of major axis:

The non-dimensional slenderness ratio,

For buckling class "b", the imperfection factor, α = 0.34

So, as per Cl. 7.1.2.1 of IS 800:2007,

Therefore, axial compression capacity in the major axis: Pdz = Axfcdz = 3,477 kN

Axial compression capacity of minor axis:

The non-dimensional slenderness ratio,

For buckling class "c", the imperfection factor, α = 0.49

So, as per Cl. 7.1.2.1 of IS 800:2007,

Therefore, axial compression capacity in the minor axis: Pdy = Axfcdy = 1,536 kN, which governs.

The critical ratio for axial compression in minor axis = 23.98 / 1,536 = 0.007

Check Shear Capacity

Major Axis

As per Cl. 8.4.1.1 of IS 800:2007, the shear area, Avz = 2×bftf + bp1tp1 + bp2tp2 = 10,692 mm2

So, as per Cl. 8.4.1,

Hence, shear capacity along major axis:

Minor Axis

As per Cl. 8.4.1.1 of IS 800:2007, the shear area, Avy = dw×tw = 4,749 mm2

So, as per Cl. 8.4.1,

Hence, shear capacity along major axis:

As per Cl. 8.4.2, dw / tw = 45.65 < 67ε, so resistance to shear buckling need not be checked.

Shear force along major axis = 2 kN.

Critical shear ratio along major axis: 2 / 1,403 = 0.001

Shear force along minor axis = 1.2 kN.

Critical shear ratio along minor axis: 1.2 / 623.2 = 0.002

Check Bending Capacity

Since the section has been classified as "plastic", βb = 1.

The section is low shear in both axes.

Major Axis Bending

Actual bending moment about the major axis is Mz = 55.98 kN·m.

The critical bending ratio in the major axis is 55.98 / 724.9 = 0.077

Minor Axis Bending

Actual bending moment about the minor axis is Mz = 10 kN·m.

The critical bending ratio in the minor axis is 10 / 124.3 = 0.080

Check Combined Interaction of Axial Compression and Bending

Section strength calculation as per Cl. 9.3.1:

n = N / Nd = 0.007 < 0.2

Hence, from Table 17:

α1 = max(5n , 1) = 1

α2 = 2

As per 9.3.1.2(b),

n1 = max(n,a) = 0.603

Therefore:

Overall member strength in bending and axial compression

ny = Fx / Pdy = 0.016

nz = Fx / Pdz = 0.007

Results

| Result Type | Reference | STAAD.Pro | Difference | Comments |

|---|---|---|---|---|

| Slenderness ratio | 108.0 | 108.08 | negligible | |

| Tension capacity, gross yielding (kN) | 3,545 | 3,545 | none | |

| Tension capacity, rupture of critical section (kN) | 4,193 | 4,163 | negligible | |

| Axial compression capacity about major axis (kN) | 3,477 | 3,477 | none | |

| Axial compression capacity about minor axis (kN) | 1,536 | 1,536 | none | |

| Critical ratio for axial compression | 0.016 | 0.016 | none | |

| Shear capacity in major axis (kN) | 1,403 | 1,403 | none | |

| Shear capacity in minor axis (kN) | 623.2 | 623.16 | negligible | |

| Ratio for shear in major axis | 0.001 | 0.001 | none | |

| Ratio for shear in minor axis | 0.002 | 0.002 | none | |

| Bending capacity about major axis (kN·m) | 724.9 | 724.745 | negligible | |

| Bending capacity about minor axis (kN·m) | 124.3 | 124.317 | negligible | |

| Ratio for bending about major axis | 0.077 | 0.077 | none | |

| Ratio for bending about minor axis | 0.080 | 0.080 | none | |

| Ratio per Cl. 9.3.1.1 | 0.086 | 0.086 | none | |

| Ratio per Eq.2 of Cl. 9.3.2.2 | 0.120 | 0.120 | none |

STAAD.Pro Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\09 Steel Design\India\IS 800 2007 LSD - I Section with Cover Plate.std is typically installed with the program.

The following design parameters are used:

- The default value of ALPHA is used.

- The default values of KY and KZ are used.

- The default value of the maximum allowable slenderness ratio, MAIN, of 180 is used.

- The beam type is a general member, specified by CAN 0

- The beam is laterally supported, specified by LAT 1

- The default values of CMX, CMY, and CMZ of 0.9 are used.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 22-Oct-08

END JOB INFORMATION

INPUT WIDTH 79

*******************************************************************************

*THIS EXAMPLE DEMONSTRATES THE DESIGN OF A WIDE FLANGE SECTION WITH

*ADDITIONAL TOP AND BOTTOM COVER PLATES USING PROVISIONS OF IS 800:2007 LSD

*******************************************************************************

SET SHEAR

UNIT METER KN

JOINT COORDINATES

1 0 0 0; 2 0 5 0; 3 5 5 0;

MEMBER INCIDENCES

1 1 2; 2 2 3;

DEFINE MATERIAL START

ISOTROPIC STEEL

E 2.05e+008

POISSON 0.3

DENSITY 76.8195

ALPHA 1.2e-005

DAMP 0.03

END DEFINE MATERIAL

MEMBER PROPERTY INDIAN

1 2 TABLE TB ISMB500 WP 0.25 TH 0.01 BW 0.2 BT 0.01

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 FIXED

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

JOINT LOAD

3 FY -2

MEMBER LOAD

2 UNI GY -2

JOINT LOAD

2 FX 1.2

2 FZ -2

SELFWEIGHT Y -1 LIST ALL

PERFORM ANALYSIS

PRINT SUPPORT REACTION

PRINT MEMBER FORCES

PARAMETER 1

CODE IS800 LSD

CAN 0 MEMB 1

LAT 1 ALL

TRACK 2 MEMB 1

CHECK CODE MEMB 1

FINISH

STAAD.Pro Output

STAAD.PRO CODE CHECKING - IS-800-2007-LSD (V2.2) **************************************************** |----------------------------------------------------------------------------------| | Member Number: 1 | | Member Section: TB ISMB500 (INDIAN SECTIONS) | | Status: PASS Ratio: 0.600 Critical Load Case: 1 Location: 0.00 | | Critical Condition: Slenderness (Compression) | | Critical Design Forces: (Unit: KN METE) | | FX: 23.984E+00 C FY: 1.200E+00 FZ: 2.000E+00 | | MX: 0.000E+00 MY: -10.000E+00 MZ: 55.980E+00 | |----------------------------------------------------------------------------------| | Section Properties: (Unit: CM ) | | AXX: 156.000E+00 IZZ: 74.381E+03 RZZ: 21.836E+00| | AYY: 47.491E+00 IYY: 3.339E+03 RYY: 4.626E+00| | AZZ: 106.920E+00 IXX: 117.000E+00 CW: 2.057E+06| | ZEZ: 2.773E+03 ZPZ: 3.189E+03 | | ZEY: 267.100E+00 ZPY: 547.000E+00 | |----------------------------------------------------------------------------------| | Slenderness Check: (Unit: KN METE) | | Actual Length: 5.000E+00 | | Parameters: LZ: 5.000E+00 LY: 5.000E+00 | | KZ: 1.000 KY: 1.000 | | Actual Ratio: 108.08 Allowable Ratio: 180.00 LOAD: 1 | |----------------------------------------------------------------------------------| | Section Class: Plastic; Flange Class: Plastic; Web Class: Plastic| |----------------------------------------------------------------------------------| STAAD SPACE -- PAGE NO. 6 STAAD.PRO CODE CHECKING - IS-800-2007-LSD (V2.2) **************************************************** |----------------------------------------------------------------------------------| | Member Number: 1 | | Member Section: TB ISMB500 (INDIAN SECTIONS) | |----------------------------------------------------------------------------------| | Tension: (Unit: KN METE) | | Parameters: FYLD: 250.000E+03 FU: 420.000E+03 | | NSF: 1.000 ALPHA: 0.800 | | Yielding : Design Force: 0.000E+00 LC: 0 | | Capacity: 3.545E+03 As per: Sec. 6.2 | | Rupture : Design Force: 0.000E+00 LC: 0 | | Capacity: 4.193E+03 As per: Sec. 6.3 | |----------------------------------------------------------------------------------| | Compression: (Unit: KN METE) | | Buckling Class: Major: b Minor: c As per:Cl. 7.1.2.2 | | Major Axis: Design Force: 23.984E+00 LC: 1 Loc: 0.000 | | Capacity: 3.477E+03 As per: Sec. 7.1.2 | | Minor Axis: Design Force: 23.984E+00 LC: 1 Loc: 0.000 | | Capacity: 1.536E+03 As per: Sec. 7.1.2 | |----------------------------------------------------------------------------------| | Shear: (Unit: KN ) | | Major Axis: Design Force: 2.000E+00 LC: 1 Loc: 0.000 | | Capacity: 1.403E+03 As per: Sec. 8.4 | | Minor Axis: Design Force: 1.200E+00 LC: 1 Loc: 0.000 | | Capacity: 623.160E+00 As per: Sec. 8.4 | |----------------------------------------------------------------------------------| | Bending: (Unit: KN METE) | | Parameters: Laterally Supported KX: 1.00 LX: 5.000E+00 General | | Major Axis: Design Force: 55.980E+00 LC: 1 Loc: 0.000 | | Capacity: 724.754E+00 As per: Sec. 8.2.1.2 | | Minor Axis: Design Force: -10.000E+00 LC: 1 Loc: 0.000 | | Capacity: 124.318E+00 As per: Sec. 8.2.1.2 | |----------------------------------------------------------------------------------| | Combined Interaction: | | Parameters: PSI: 1.00 CMX: 0.900 CMY: 0.900 CMZ: 0.900 | | Section Strength: Ratio: 0.086 As per: Sec. 9.3.1.1 | | LC: 1 Loc: 0.000 | | Overall Member Strength (Bending+Compression): | | Equation 2: Ratio: 0.120 As per: Sec. 9.3.2.2 Ky : 1.0125 | | LC: 1 Loc: 0.000 Kz : 1.0004 | |----------------------------------------------------------------------------------| | Checks Ratio Load Case No. Location from Start( METE) | | | | Tension 0.000 0 0.000E+00 | | Compression 0.016 1 0.000E+00 | | Shear Major 0.001 1 0.000E+00 | | Shear Minor 0.002 1 0.000E+00 | | Bend Major 0.077 1 0.000E+00 | | Bend Minor 0.080 1 0.000E+00 | | Sec. 9.3.1.1 0.086 1 0.000E+00 | | Sec. 9.3.2.2(ii) 0.120 1 0.000E+00 | |----------------------------------------------------------------------------------|