V.ASCE 7 Torsion Irregularity

Verify the torsional irregularity check per the ASCE 7-16 specifications.

Details

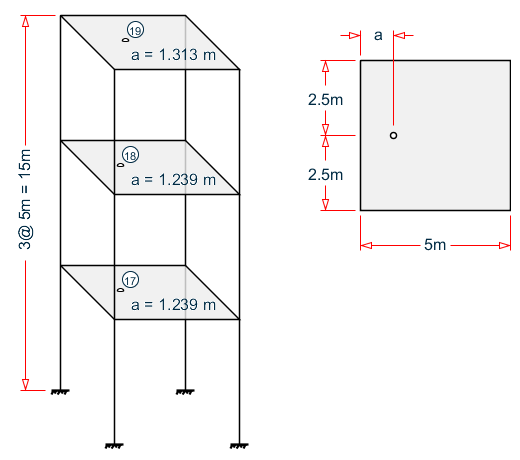

A three story building is modelled with floor diaphragms defined at each floor level.

A 1 kip (4.4482 kN) load is applied to each diaphragm in both the global X and Z directions. In STAAD.Pro, this is modelled using an analytical node in each diaphragm. This is used to obtain the displacements in the nodes of the diaphragm.

Nodes 17, 18, and 19 are the control nodes in each diaphragm.

Nodes 17, 18, and 19 are the control nodes in each diaphragm.Validation

The displacements induced because of the applied loads on the control nodes for the nodes situated on the extremities of each diaphragm is taken from the STAAD.Pro output for each lateral direction.

| Diaphragm | Control Node | Primary LC Number | Diaphragm Extremities | Displacements (mm) | Δmax/Δmin | Status | ||

|---|---|---|---|---|---|---|---|---|

| Extreme Node 1 | Extreme Node 2 | Δx Extreme Node 1 | Δx Extreme Node 2 | |||||

| 1 | 17 | 1 | 2 or 3 | 6 or 7 | 0.0482 × 10 = 0.482 | 0.0482 × 10 = 0.482 | 0.482/0.482 = 1 | OK |

| 2 | 18 | 2 | 9 or 10 | 11 or 12 | 0.2443 × 10 = 2.443 | 0.2443 × 10 = 2.443 | 2.443/2.443 = 1 | OK |

| 3 | 19 | 3 | 13 or 14 | 15 or 16 | 0.6090 × 10 = 6.090 | 0.6090 × 10 = 6.090 | 6.090/6.090 = 1 | OK |

| Diaphragm | Control Node | Primary LC Number | Diaphragm Extremities | Displacements (mm) | Δmax/Δmin | Status | ||

|---|---|---|---|---|---|---|---|---|

| Extreme Node 1 | Extreme Node 2 | Δz Extreme Node 1 | Δz Extreme Node 2 | |||||

| 1 | 17 | 4 | 2 or 6 | 3 or 7 | 0.0234 × 10 = 0.234 | 0.0361 × 10 = 0.361 | 0.361/0.234 = 1.543 | FAIL |

| 2 | 18 | 5 | 9 or 11 | 10 or 12 | 0.0919 × 10 = 0.919 | 0.1243 × 10 = 1.243 | 1.243/0.919 = 1.353 | OK |

| 3 | 19 | 6 | 13 or 15 | 14 or 16 | 0.1884 × 10 = 1.884 | 0.2441 × 10 = 2.441 | 2.441/1.884 = 1.296 | OK |

Results

| Result Type | Reference | STAAD.Pro | Difference | Comments | |

|---|---|---|---|---|---|

| X Direction | 1 | OK | OK | none | |

| 2 | OK | OK | none | ||

| 3 | OK | OK | none | ||

| Z Direction | 1 | Fail | Fail | none | |

| 2 | OK | OK | none | ||

| 3 | OK | OK | none | ||

STAAD.Pro Input File

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\06 Loading\IBC\IBC 2018 Torsion Irregularity.STD is typically installed with the program.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 05-Mar-19

END JOB INFORMATION

INPUT WIDTH 79

UNIT METER KN

JOINT COORDINATES

1 0 0 0; 2 0 5 0; 3 5 5 0; 4 5 0 0; 5 0 0 5; 6 0 5 5; 7 5 5 5; 8 5 0 5;

9 0 10 0; 10 5 10 0; 11 0 10 5; 12 5 10 5; 13 0 15 0; 14 5 15 0; 15 0 15 5;

16 5 15 5; 17 1.239 5 2.5; 18 1.239 10 2.5; 19 1.313 15 2.5

MEMBER INCIDENCES

1 1 2; 2 2 3; 3 3 4; 4 2 6; 5 3 7; 6 5 6; 7 6 7; 8 7 8; 9 2 9; 10 3 10;

11 6 11; 12 7 12; 13 9 10; 14 9 11; 15 10 12; 16 11 12; 17 9 13; 18 10 14;

19 11 15; 20 12 16; 21 13 14; 22 13 15; 23 14 16; 24 15 16;

DEFINE MATERIAL START

ISOTROPIC CONCRETE

E 2.17185e+07

POISSON 0.17

DENSITY 23.5616

ALPHA 1e-05

DAMP 0.05

TYPE CONCRETE

STRENGTH FCU 27579

END DEFINE MATERIAL

MEMBER PROPERTY AMERICAN

2 3 5 7 8 10 12 13 15 16 18 20 21 23 24 PRIS YD 0.35 ZD 0.25

MEMBER PROPERTY AMERICAN

1 4 6 9 11 14 17 19 22 PRIS YD 0.5 ZD 0.65

CONSTANTS

MATERIAL CONCRETE ALL

SUPPORTS

1 4 5 8 FIXED

MEMBER CRACKED

1 3 6 8 TO 12 17 TO 20 REDUCTION RIY 0.7 RIZ 0.7

2 4 5 7 13 TO 16 21 TO 24 REDUCTION RIY 0.35 RIZ 0.35

DEFINE REFERENCE LOADS

LOAD R1 LOADTYPE Mass TITLE REF LOAD CASE 1

SELFWEIGHT X 1

SELFWEIGHT Y 1

SELFWEIGHT Z 1

END DEFINE REFERENCE LOADS

FLOOR DIAPHRAGM

DIA 1 TYPE RIG HEI 5

DIA 2 TYPE RIG HEI 10

DIA 3 TYPE RIG HEI 15

*CHECK IRREGULARITIES CODE IS1893 2016

CHECK IRREGULARITIES CODE ASCE7

DEFINE IBC 2018

ZIP 92887 I 1 RX 3 RZ 4 SCLASS 1 TL 8

LOAD 1 LOADTYPE None TITLE Diaphragm 1 Unit Load FX

JOINT LOAD

17 FX 4.4482

LOAD 2 LOADTYPE None TITLE Diaphragm 2 Unit Load FX

JOINT LOAD

18 FX 4.4482

LOAD 3 LOADTYPE None TITLE Diaphragm 3 Unit Load FX

JOINT LOAD

19 FX 4.4482

LOAD 4 LOADTYPE None TITLE Diaphragm 1 Unit Load FZ

JOINT LOAD

17 FZ 4.4482

LOAD 5 LOADTYPE None TITLE Diaphragm 2 Unit Load FZ

JOINT LOAD

18 FZ 4.4482

LOAD 6 LOADTYPE None TITLE Diaphragm 3 Unit Load FZ

JOINT LOAD

19 FZ 4.4482

PERFORM ANALYSIS

PRINT ANALYSIS RESULTS

PRINT DIA CR

FINISH

STAAD.Pro Output

STAAD.PRO IRREGULARITIES CHECK - ( ASCE7-2016 ) v1.0 ********************************************************* --TORSION IRREGULARITY CHECKS Torsion Irregularity Check Ref: Fig. C12.3-1 T1- Ratio Limit(s): 1.20, 1.40 ------------------------------------------------ Dia. Extreme Points of Dia in X Extreme Points of Dia in Z Node Disp. Node Disp. Node Disp. Node Disp. (mm) (mm) (mm) (mm) ------------------------------------------------------------------------ 1 7 0.48231 2 0.48231 3 0.36107 2 0.23351 2 12 2.44302 9 2.44302 10 1.24284 9 0.91874 3 16 6.08970 13 6.08970 14 2.44124 13 1.88424 Diaphragm D X-max/avg D Z-max/avg Status -------------------------------------- 1 1.0000 1.2145 FAIL 2 1.0000 1.1499 OK 3 1.0000 1.1288 OK --GEOMETRY IRREGULARITY CHECKS Re-Entrant Corner Check. (Ref: Fig. C12.3-1 T2- Ratio Limit: 0.15 ) ------------------------------------------ ***NOTE: No Irregular Re-Entrant Nodes found in the diaphragm. ***NOTE: No Irregular Re-Entrant Nodes found in the diaphragm. ***NOTE: No Irregular Re-Entrant Nodes found in the diaphragm. --MASS IRREGULARITY CHECKS Mass Irregularity Check Ref: Fig. C12.3-2 T2- Ratio Limit: 1.50 --------------------------------------- Dia. Level Mass Above Below Ratio Ratio Status ( m) ( kN) ( kN) ( kN) Above Below --------------------------------------------------------------------- 1 5.000 166.404 166.404 Base 1.000 N/A OK 2 10.000 166.404 117.808 166.404 1.412 1.000 OK 3 15.000 117.808 Top 166.404 N/A 0.708 OK