D1.D.2.2 Capacities per AASHTO (LRFD) Code

Axial Strength

The criteria governing the capacity of tension members is based on two limit states. The limit state of yielding in the gross section is intended to prevent excessive elongation of the member. The second limit state involves fracture at the section with the minimum effective net area. The net section area may be specified through the use of the parameter NSF. STAAD calculates the tension capacity of a given member based on these two limit states and proceeds with member selection or code check accordingly

| Pr = φyPny = φyFyAg |

| Pr = φuPnu = φuFuAnU |

| = | ||

| = | ||

| = | ||

| = | ||

| = | ||

| = | ||

| = | ||

| = | ||

| = |

Allowable compressive stress on the gross section of axially loaded compression members is calculated based on the following formula:

if λ ≤ 2.25

Nominal compressive resistance,

Pn = 0.66λFyAs

if λ > 2.25

Nominal compressive resistance

| Pn = 0.88FyAs/λ |

| = |

The Factored resistance

Pr = φc Pn

Bending Strength

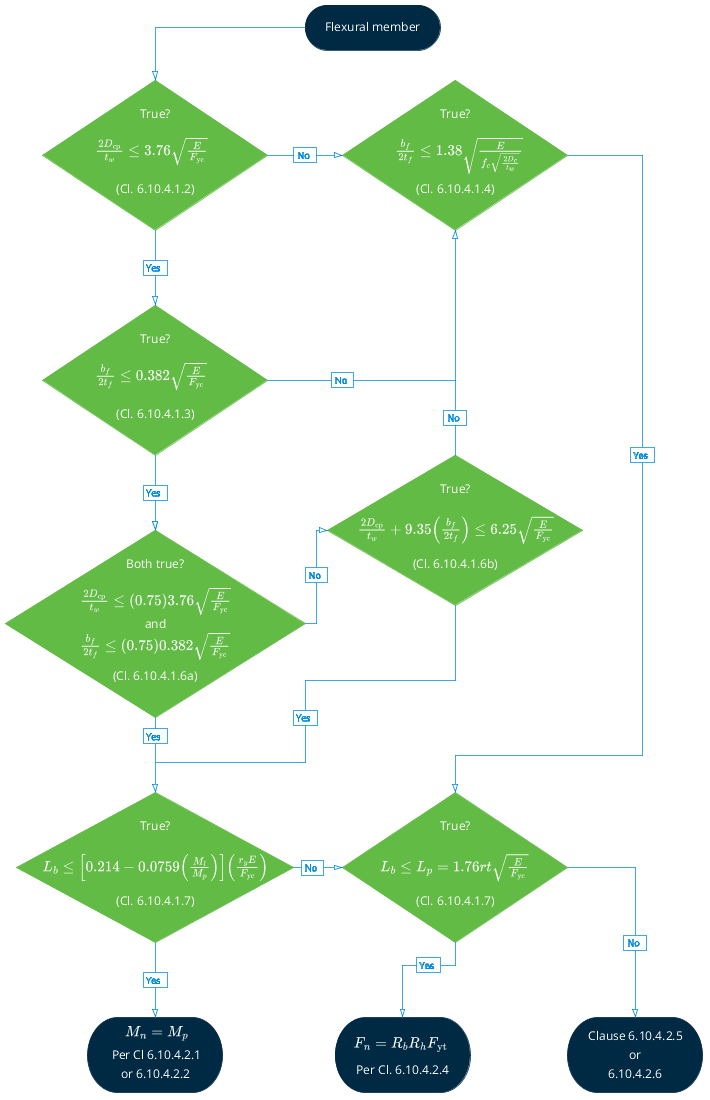

The flow to calculate the allowable bending strength for rolled shape girders and built-up sections is given by the flowing flow chart.

Flow used to calculate the allowable bending strength for rolled shape girders and built-up sections

Shear Strength

The nominal shear resistance of un-stiffened webs of homogeneous girders shall be calculated as.

If D/tw ≤ 2.46√(E/Fy), then

Vn = Vp =0.58FywDtw

If 2.46√(E/Fy) < D/tw ≤ 3.07√(E/Fy), then

Vn = 1.48·tw 2√(E·Fy)

If D/tw > 3.07√(E/Fy), then

Vn = 4.55·tw 3·E/D

Bending-Axial Interaction

Members subjected to both axial forces and bending moments are proportioned according to section 6.9.2.2 of the AASHTO steel code. All members subject to bending and axial compression or axial tension are required to satisfy the following formula:

If Pu/Pr < 0.2, then

If Pu/Pr ≥ 0.2, then