V. AASHTO 2nd Ed LRFD - Design Beam

The following compares the solution of a design performed using STAAD.Pro against a hand calculation of steel design per the AASHTO (LRFD) code.

Details

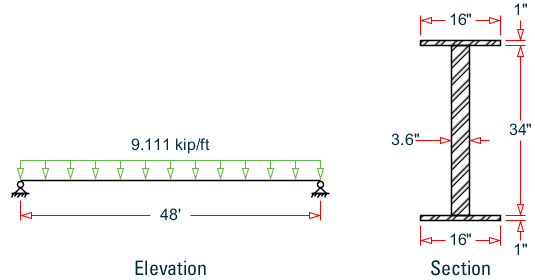

Determine the allowable resistances (AASHTO LRFD, 1998 code) for the member of the structure as shown in figure. Also, perform a code check for the member based on the results of the analysis.

A 48 foot long, non-composite girder is assumed to be simply supported. The section is a plate girder with 16" x 1" plate flanges and a 34" x 3.6" plate web (36 in. total depth). All plates are grade 36 steel.

The beam is subject to a 9.111 kip/ft uniform load.

| A = 154.4 in2, Iz = 21,594 in4, Iy = 814.9 in4 |

| Sz = 21,594(2)/36 = 1,200 in3 |

From observation Load case 1 will govern,

Mz = 2,624 kip-ft

Axial Compression Capacity

Refer Clause 6.9.4 of the code.

| (kL/r)y = 0.333 × 576/ 2.297 = 83.50 |

| (kL/r)z = 1 × 576/ 11.826 = 48.71 |

| (kL/r)crit = 83.50 < 120, ok. |

Calculation of Width/Thickness ratio for axial compression

Plate buckling coefficients taken from Table 6.9.4.2-1:

kw = 1.49, kf = 0.56

Slenderness ratio for the web:

(d - 2·tf)/tw = (36 - 2 · 1) / 3.6 = 9.444

Slenderness ratio for the 1/2 flange:

bf/(2·tf) = 16/(2 · 1) = 8.0

Critical ratio for web:

Critical ratio for flange:

Thus, OK [AASHTO LRFD Cl. 6.4.9.2]

Slenderness ratio about major and minor axis:

λy governs, thus λ = 0.877

λ < 2.25, so Equation 6.9.4.1-1 is used to determine the nominal compressive resistance

Pn = 0.66λFyAs = 0.660.877·36·154.4 = 3,861 kips

The factored compressive resistance, Pr = φcPn = 0.9 · 3,861 = 3,475 kips

Major Axis Bending Capacity

The compression flange moment of inertia:

| Iyc = 1(16)3/12 = 341.3 in4 |

| Iyc/Iy = 341.3/814.9 = 0.419, > 0.1 and < 0.9 |

Thus, OK [AASHTO LRFD Cl. 6.10.2.1]

Thus, OK [AASHTO LRFD Cl. 6.10.2.2]

Calculation of depth of the web in compression at the plastic moment, Dcp(Clause 6.10.3.3.2)

Area of Web, Aw = (36 – 2 × 1) × 3.6 = 122.4 in2

Area of flange area in tension, Aft = Area of flange in compression, Afc = 16 × 1 = 16 in2

Thus, OK [AASHTO LRFD Cl. 6.10.4.1.2]

Thus, OK [AASHTO LRFD Cl. 6.10.4.3]

Check clause 6.10.4.1.6a

| (B/t)flange < 0.75 × (B/t)flange_limit = 0.75 ×10.978 |

| (D/T)web < 0.75 × (D/T)web_limit =0.75×108.057 |

Check clause 6.10.4.1.7

| Mpz = Pz × Fy= 1,600 in3(36 ksi) = 57,614 in-k |

Unsupported length, Lu = 576 in > Lb.; section is non-compact.

Check clause 6.10.4.1.9

A notional section comprised of the compression flange and one-third of the depth of the web in compression, taken about the vertical axis.

| Lb > Lp |

Clause 6.10.4.2.6

Minimum radius of gyration of the compression flange taken about the vertical axis:

Hybrid factor, Rh = 1.0 (For Homogeneous sections, Hybrid factors shall be taken as 1.0 per clause 6.10.4.3.1)

As per clause 6.10.4.3.2, Load-shedding factor, Rb

If area of the compression flange, Acf ≥ the area of the tension flange, Atf

| lb= 5.76 |

| Dc = 17.00 |

Thus:

Rb,comp = Rb,ten = 1.0

Lr < Lb

Cb = 1.75 + 1.05(M1/M2)+0.3x(M1/M2)2

Here M1 = 0, M2 = 0 so Cb = 1.75

| Mnz = 19,000 kip·in |

Resisting Moment

Mr = Qf · Mn= 1.0 (19,000) = 19,000 kip·in

Actual Moment = 31,488 kip·in

Interaction ratio = 31,488 / 19,000 = 1.657

STAAD Input

The following input is used in this verification example.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 23-May-11

END JOB INFORMATION

INPUT WIDTH 79

UNIT FEET KIP

JOINT COORDINATES

1 0 0 0; 2 38 0 0;

MEMBER INCIDENCES

1 1 2;

START USER TABLE

TABLE 1

UNIT INCHES KIP

WIDE FLANGE

AASHTOGIRDER

154.4 36 3.6 16 1 21593.8 814.86 539.4 129.6 32

END

UNIT FEET KIP

DEFINE MATERIAL START

ISOTROPIC STEEL

E 29000

POISSON 0.3

DENSITY 0.000283

ALPHA 6e-06

DAMP 0.03

TYPE STEEL

STRENGTH FY 36 FU 58 RY 1.5 RT 1.2

END DEFINE MATERIAL

MEMBER PROPERTY AMERICAN

1 UPTABLE 1 AASHTOGIRDER

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 PINNED

2 FIXED BUT FX MY MZ

UNIT INCHES KIP

LOAD 1 LOADTYPE None TITLE LOAD CASE 1

MEMBER LOAD

1 UNI GY -0.76

PERFORM ANALYSIS

PARAMETER 1

CODE AASHTO LRFD

TRACK 2 ALL

CHECK CODE ALL

FINISH

STAAD Output

STAAD.PRO CODE CHECKING - ( AASHTO - LRFD) v1.0 ******************************************** * 1 ST AASHTOGIRDER (UPT) FAIL Slenderness 1.654 1 0.00 0.00 0.00 0.00 Section Properties (in) ----------------------- Ax = 154.40 Ay = 129.60 Az = 32.00 Iz = 21593.80 Iy = 814.86 Rz = 11.83 Ry = 2.30 Sz = 1199.66 Sy = 101.86 Input Parameters (Kip-in) -------------------------- Fyld = 36.00 Fu = 58.00 Lz = 456.00 Ly = 456.00 Kz = 1.00 Ky = 1.00 UNL = 0.00 Ratio = 1.00 Design Results (Kip-in) ----------------------- Klrz = 38.56 Klry = 198.49 CBy = 0.00 CBz = 0.00 CAPACITIES (Kip-in) -------------------- Compressive Capacity = 0.00 Tensile Capacity = 0.00 Moment Capacity_y = 0.00 Moment Capacity_z = 0.00 Shear Capacity = 0.00 DESIGN FORCES (Kip-in) ----------------------- Compressive Force = 0.00 Tensile Force = 0.00 Moment Y = 0.00 Moment Z = 0.00 Shear Force = 173.28