V. AISC LRFD - Select Wide Flange 2

To find the optimum W shape with a flexural design strength of 150 ft·kips. Beam is braced at ends and at mid-span point.

Reference

AISC. Load and Resistance Factor Design Specification, 3rd Edition. 1999. Example 5.4, page 5-21.

AISC. Manual of Steel Construction, 3rd Edition. 1999.

Details

The beam should also satisfy a deflection limit of 1.0 inches under service load.

| Fy = 50 ksi |

| Length = 20 ft |

| Lb = 10 ft |

Service load of 2.0 kip/ft. Deflection limit under service load = 1.0 in.

Validation

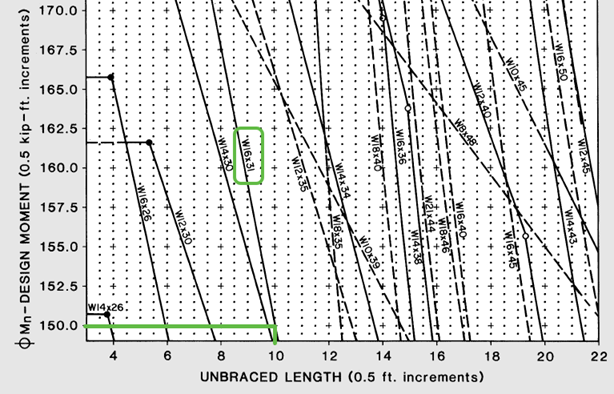

From the chart on p.4-160 of the Manual of Steel Construction, the most efficient wide-flange section to resist 150 kip-ft of moment with an unbraced length of 10 ft is a W16x31. From this same chart, the design bending strength can be taken as 150 kip-ft (the curve crosses at approximately the same point as the demand load).

The deflection limit under service conditions can be met by determining the minimum required moment of inertia needed.

Solving for the minimum I = 248 in4. A W16x31 has an Ix = 375 in4, so it will have less deflection than the limit under service conditions.

Results

| Result Type | Theory | STAAD.Pro | Difference | Comments |

|---|---|---|---|---|

| Optimum Section | W16x31 | W16x31 | none | |

| Design bending strength, ϕbMn (in·kips) | 1,800

(150 ft·kips) |

1,801.66 | negligible | |

| Maximum permissible deflection (in) | 1.0 | 0.6584 | N/A | The STAAD.Pro reported maximum deflection is less than 1.0 in; therefore this section satisfies the requirement. However, this value is not to be directly compared with the limit itself. |

STAAD Input

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ Verification Models\09 Steel Design\US\AISC\AISC LRFD - Select Wide Flange 2.STD is typically installed with the program.

STAAD SPACE BENDING PER AISC LRFD 3RD ED

START JOB INFORMATION

ENGINEER DATE 23-Sep-18

END JOB INFORMATION

*

* EXAMPLE 5.4, PAGE 5-21, AISC LRFD 3RD ED.

* OBJECTIVE : TO FIND THE OPTIMUM W SHAPE WITH A FLEXURAL

* DESIGN STRENGTH OF 150 KIP-FT.

*

* ACCORDING TO ABOVE REFERENCE, THE SECTION SHOULD BE W16X31

*

UNIT FEET KIP

JOINT COORDINATES

1 0 0 0; 2 20 0 0;

MEMBER INCIDENCES

1 1 2;

MEMBER PROPERTY AMERICAN

1 TABLE ST W12X26

UNIT INCHES KIP

DEFINE MATERIAL START

ISOTROPIC MATERIAL1

E 29000

POISSON 0.3

END DEFINE MATERIAL

UNIT FEET KIP

CONSTANTS

MATERIAL MATERIAL1 ALL

SUPPORTS

1 PINNED

2 FIXED BUT MZ

LOAD 1

MEMBER LOAD

1 UNI GY -2

LOAD COMBINATION 2

1 1.5

PERFORM ANALYSIS

LOAD LIST 2

UNIT INCHES KIP

PARAMETER 1

CODE LRFD

MAIN 1 ALL

UNT 120 ALL

FYLD 50 ALL

TRACK 1 ALL

SELECT ALL

LOAD LIST ALL

PERFORM ANALYSIS

LOAD LIST 1

SECTION 0.5 ALL

PRINT SECTION DISPL

LOAD LIST 2

CHECK CODE ALL

FINISH

STAAD Output

STAAD.Pro MEMBER SELECTION - (LRFD 3RD EDITION) v1.0 ************************** ALL UNITS ARE - KIP INCH (UNLESS OTHERWISE Noted) MEMBER TABLE RESULT/ CRITICAL COND/ RATIO/ LOADING/ FX MY MZ LOCATION ======================================================================= 1 ST W16X31 (AISC SECTIONS) PASS LRFD-H1-1B-C 0.999 2 0.00 C 0.00 -1800.00 120.00 +---------------------------------------------------------------------+ | DESIGN STRENGTHS FOR MEMBER 1 UNITS - KIP IN | | PNC= 45.93 PNT= 410.85 MNZ= 1801.66 MNY= 302.71 VN= 118.06 | +---------------------------------------------------------------------+ ************** END OF TABULATED RESULT OF DESIGN ************** 46. LOAD LIST ALL 47. PERFORM ANALYSIS 48. LOAD LIST 1 49. SECTION 0.5 ALL 50. PRINT SECTION DISPL SECTION DISPL BENDING PER AISC LRFD 3RD ED -- PAGE NO. 4 MEMBER SECTION DISPLACEMENTS ---------------------------- UNITS ARE - INCH MEMB LOAD GLOBAL X,Y,Z DISPL FROM START TO END JOINTS AT 1/12TH PTS 1 1 0.0000 0.0000 0.0000 0.0000 -0.1731 0.0000 0.0000 -0.3331 0.0000 0.0000 -0.4690 0.0000 0.0000 -0.5722 0.0000 0.0000 -0.6365 0.0000 0.0000 -0.6584 0.0000 0.0000 -0.6365 0.0000 0.0000 -0.5722 0.0000 0.0000 -0.4690 0.0000 0.0000 -0.3331 0.0000 0.0000 -0.1731 0.0000 0.0000 0.0000 0.0000 MAX LOCAL DISP = 0.65839 AT 120.00 LOAD 1 L/DISP= 364 ************ END OF SECT DISPL RESULTS ***********