V. GB500017-2017 H-section with Combined Axial and Bending

Verify the strength, stability, and slenderness of an H section subject to combined axial and bending per GB50017-2017.

Reference

MOHURD. 2017. GB 50017-2017 Standard for design of steel structures . Beijing, China: Ministry of Housing and Urban-Rural Development

Problem

The section is an HN400x408 with a length of 9 m. The structure is a two-story frame. Member #1 assigned with an H-section (HN400x408) is designed per GB 50017-2017. The section has an unbraced length of 4.5 m about the x direction and 9 m about the y direction.

Material Properties

The material is Q235 type steel.

- Design strength in tension, compression, and flexure: fy = 205 MPa

- Design strength in shear: fv = 120 MPa

Section Properties

- Section depth, h = 400 mm

- Section width, b = 408 mm

- Flange thickness, tf = 21 mm

- Web thickness, tw = 21 mm

- Cross-sectional area, A = 25,069 mm2

- Moment of inertia about x, Ix = 708,880,000 mm4

- Moment of inertia about y, Iy = 238,090,000 mm4

- Radius of gyration about x, ix = 168.2 mm

- Radius of gyration about y, iy = 97.5 mm

- Area moment about x, Sx = 3,544,400 mm3

- Area moment about y, Sx = 1,167,100 mm3

Calculations

Slenderness Ratio

The effective length is:

lox = μx×lx = 1.581 × 4,500 mm = 7,115 mm

loy = μy×ly = 1.319 × 9,000 mm = 11,870 mm

The slenderness ratio is:

Ratio for tension slenderness: 42.3 / 150 = 0.28

Ratio for compression slenderness: 121.8 / 150 = 0.81

Steel Grade Correction Factor

The steel type is Q235. According to note 1 in table 3.5.1 of Standard for design of steel structures and table 1 of Standard for design of steel structures. Commentary 2.2, the steel grade correction coefficient is εk = 1.

Overall Stability Coefficient

According to the formula (C.0.1) in Appendix C of Standard for design of steel structures, the overall stability coefficient of the beam determined by the bending around the strong axis is calculated as:

According to the formula (c.0.1-7) in Appendix C of Standard for design of steel structures,

So, for the section in x-x direction, .

Stability Factor for Axial Compression

According to the formula (D.0.5) in Appendix D of Standard for design of steel structures,

For section y-y direction:

Class c, so, the coefficients are α1 = 0.730, α2 = 1.126, and α3 = 0.302.

Since , then the stability factor in y:

For section x-x direction:

Class b, so, the coefficients are α1 = 0.650, α2 = 0.965, and α3 = 0.300.

Since , then the stability factor in x:

Equivalent Moment Factor

The critical buckling load:

For an unbraced frame:

Because there is a reverse bending point, M1 and M2 have different signs:

Section influence coefficient, η = 1.0

Plastic Development Coefficient

According to clause 6.1.2 of Standard for design of steel structures, and the width thickness ratio of cross-section plate is grade S3,

γx = 1.05

γy = 1.20

Check Web Thickness to Height Ratio

Calculated the web height:

h0 = 400 - 21 - 21 = 358 mm

According to table 3.5.1 of Standard for design of steel structures, and the width thickness ratio of cross-section plate is grade S3, so the limit value of height thickness ratio is:

| 40 + 18 × ɑ01.5 |

| = |

| = |

| = |

Therefore, the limit value is: 40 + 18 × 0.0011.5 = 40.00

Ratio:

Check Flange Thickness to Width Ratio

According to table 3.5.1 of Standard for design of steel structures, and the width thickness ratio of cross-section plate is grade S3, so the limit value of width thickness ratio is:

Ratio:Shear Strength

The controlling load condition for shear is combination 10. F : 1.20DL+1.40LL+0.84WL:

Vx = 46.5 kN

Vy = 9.52 kN

Take the neutral axis as the calculation point of shear stress, calculate the area moment:

Sx = 1,960,000 mm3

Sy = 893,700 mm3

According to clause 6.1.3 of Standard for design of steel structures, shear stress

τmax = 6.12 < fv = 120 N/mm2

Therefore, the ratio is:

Check In-plain Stability

The controlling load condition for in-plane stability is combination 14. F : 1.2DL+1.4LL+0.84WF:

Mx = 174.8 kN·m

My = 58.75 kN·m

N = 181.2 kN

According to clause 8.2.5 of Standard for design of steel structures,

| (Cl. 8.2.5) |

Check Out-of-plain Stability

The controlling load condition for in-plane stability is combination 14. F : 1.2DL+1.4LL+0.84WF:

Mx = 174.8 kN·m

My = 58.75 kN·m

N = 181.2 kN

According to clause 8.2.5 of Standard for design of steel structures,

| (Cl. 8.2.5) |

Strength of the Member

The controlling load condition for strength is combination 14. F : 1.2DL+1.4LL+0.84WF:

According to Clause 8.1.1 of Standard for design of steel structures,

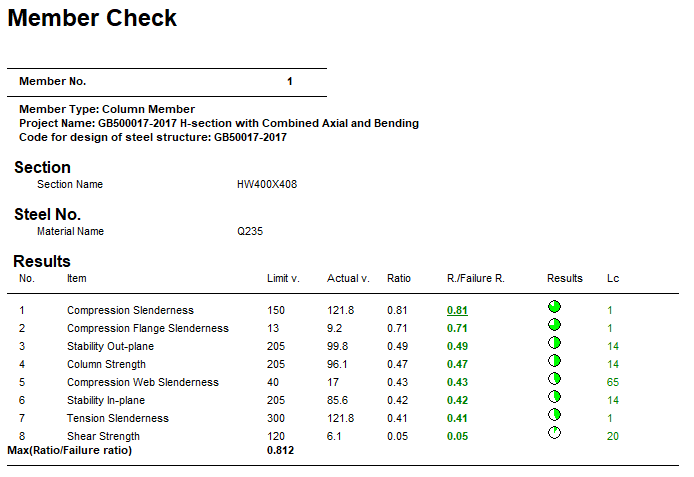

Comparison

| Result Type | Reference | STAAD.Pro | Difference | Comment |

|---|---|---|---|---|

| Column Strength | 0.47 | 0.47 | none | |

| In-plane Stability | 0.42 | 0.42 | none | |

| Out-plane Stability | 0.49 | 0.49 | none | |

| Compression Slenderness | 0.81 | 0.81 | none | |

| Tension Slenderness | 0.41 | 0.41 | none | |

| Shear Strength | 0.05 | 0.05 | none | |

| Flange Slenderness | 0.71 | 0.71 | none |

STAAD.Pro Input File

The file C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\ \Verification Models\09 Steel Design\China\GB500017-2017 H-section with Combined Axial and Bending.STD is typically installed with the program.

STAAD SPACE

START JOB INFORMATION

ENGINEER DATE 03-Aug-18

END JOB INFORMATION

INPUT WIDTH 79

UNIT METER KN

JOINT COORDINATES

1 0 0 0; 2 0 4.5 0; 3 0 9 0; 5 10 0 0; 6 10 4.5 0; 7 10 9 0; 17 0 0 6;

18 0 4.5 6; 19 0 9 6; 20 10 0 6; 21 10 4.5 6; 22 10 9 6; 23 2.5 4.5 6;

24 5 4.5 6; 25 7.5 4.5 6; 26 2.5 4.5 0; 27 5 4.5 0; 28 7.5 4.5 0; 29 2.5 9 0;

30 5 9 0; 31 7.5 9 0; 32 2.5 9 6; 33 5 9 6; 34 7.5 9 6;

MEMBER INCIDENCES

1 1 2; 2 2 3; 4 2 26; 5 3 29; 7 5 6; 8 6 7; 23 3 19; 24 6 21; 25 7 22;

30 17 18; 31 18 19; 32 18 23; 33 19 32; 34 20 21; 35 21 22; 36 23 24; 37 24 25;

38 25 21; 39 26 27; 40 27 28; 41 28 6; 42 29 30; 43 30 31; 44 31 7; 45 32 33;

46 33 34; 47 34 22; 48 23 26; 49 24 27; 50 25 28; 51 32 29; 52 33 30; 53 34 31;

DEFINE MATERIAL START

ISOTROPIC STEEL

E 2.05e+08

POISSON 0.3

DENSITY 76.8195

ALPHA 1.2e-05

DAMP 0.03

TYPE STEEL

STRENGTH FY 253200 FU 407800 RY 1.5 RT 1.2

END DEFINE MATERIAL

MEMBER PROPERTY CHINESE

1 2 7 8 30 31 34 35 TABLE ST HW400X408

4 5 32 33 36 TO 47 TABLE ST HN500X200

23 TO 25 48 TO 53 TABLE ST HN300X150

CONSTANTS

MATERIAL STEEL ALL

SUPPORTS

1 5 17 20 FIXED

DEFINE WIND LOAD

*{ TYPE AUTO, DON'T MODIFY FOLLOWING DATA

TYPE 2

INT 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 HEIG 0.9 1.8 2.7 3.6 -

4.5 5.4 6.3 7.2 8.1 9

*{ END MAIN TYPE

*{ END INCLINE TYPE

LOAD 1 LOADTYPE None TITLE DL

SELFWEIGHT Y -1

MEMBER LOAD

23 TO 25 48 TO 53 UNI GY -12.5

LOAD 2 LOADTYPE None TITLE LL

MEMBER LOAD

23 TO 25 48 TO 53 UMOM GY -10

LOAD 3 WL AUTO WIND LOAD

*{ THE FIRST AUTO BUILD WIND LOAD

*{ 自动定义的风荷载的类型号

*{ TYPE NO : 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

*{ 建筑结构的总高度

*{ STRUCTURE HIGH : 9

*{ 是否考虑风振系数的影响

*{ IS BETAZ : 0

*{ 建筑结构基本自振周期

*{ BASE PERIOD : 0.5

*{ 基本风压值

*{ BASE PRESS : 0.35

*{ 场地土粗造度类别

*{ SOIL TYPE : B

*{ 四个风向的迎风面宽度

*{ AWEATHER WIDTH : 6 6 10 10

*{ 四个风向的迎风面宽度

*{ AWEATHER WIDTH : 6 6 10 10

*{ 结构类型(空间或平面)

*{ STRUCTURE TYPE 2

*{ 风荷载体型系数,四个风向,四个面

*{ LEFTWIND MIUS : 0.8 -0.5 -0.6 -0.6

*{ RIGHTWIND MIUS : -0.5 0.8 -0.6 -0.6

*{ FRONTWIND MIUS : -0.6 -0.6 0.8 -0.5

*{ BACKWIND MIUS : -0.6 -0.6 -0.5 0.8

*{ 计算风压强度/高度曲线的方式

*{ INTENSITY FLAG : 1

*{ 用户指定需要计算风压强度的点数

*{ INTENSITY NUMBER : 10

*{ 等距离计算风压强度时的距离值

*{ INTENSITY ISOMETRY : 5

*{ 按照层高计算各点风压强度时的层高度

*{ INTENSITY FLOOR : 4.5

WIND LOAD X 0.8 TYPE 2

WIND LOAD -X 0.5 TYPE 2

WIND LOAD -Z 0.6 TYPE 2

WIND LOAD -Z -0.6 TYPE 2

LOAD 4 WR AUTO WIND LOAD

*{ AUTO BUILD WIND LOAD

WIND LOAD X -0.5 TYPE 2

WIND LOAD -X -0.8 TYPE 2

WIND LOAD -Z 0.6 TYPE 2

WIND LOAD -Z -0.6 TYPE 2

LOAD 5 WF AUTO WIND LOAD

*{ AUTO BUILD WIND LOAD

WIND LOAD -X -0.6 TYPE 2

WIND LOAD -X 0.6 TYPE 2

WIND LOAD -Z -0.8 TYPE 2

WIND LOAD Z -0.5 TYPE 2

LOAD 6 WB AUTO WIND LOAD

*{ AUTO BUILD WIND LOAD

WIND LOAD -X -0.6 TYPE 2

WIND LOAD -X 0.6 TYPE 2

WIND LOAD -Z 0.5 TYPE 2

WIND LOAD Z 0.8 TYPE 2

LOAD COMB 7 F : 1.20DL

1 1.2

LOAD COMB 8 F : 1.20DL+1.40LL

1 1.2 2 1.4

LOAD COMB 9 F : 1.20DL+0.84WL

1 1.2 3 0.84

LOAD COMB 10 F : 1.20DL+1.40LL+0.84WL

1 1.2 2 1.4 3 0.84

LOAD COMB 11 F : 1.20DL+0.84WR

1 1.2 4 0.84

LOAD COMB 12 F : 1.20DL+1.40LL+0.84WR

1 1.2 2 1.4 4 0.84

LOAD COMB 13 F : 1.20DL+0.84WF

1 1.2 5 0.84

LOAD COMB 14 F : 1.20DL+1.40LL+0.84WF

1 1.2 2 1.4 5 0.84

LOAD COMB 15 F : 1.20DL+0.84WB

1 1.2 6 0.84

LOAD COMB 16 F : 1.20DL+1.40LL+0.84WB

1 1.2 2 1.4 6 0.84

LOAD COMB 17 F : 1.00DL

1 1.0

LOAD COMB 18 F : 1.00DL+1.40LL

1 1.0 2 1.4

LOAD COMB 19 F : 1.00DL+0.84WL

1 1.0 3 0.84

LOAD COMB 20 F : 1.00DL+1.40LL+0.84WL

1 1.0 2 1.4 3 0.84

LOAD COMB 21 F : 1.00DL+0.84WR

1 1.0 4 0.84

LOAD COMB 22 F : 1.00DL+1.40LL+0.84WR

1 1.0 2 1.4 4 0.84

LOAD COMB 23 F : 1.00DL+0.84WF

1 1.0 5 0.84

LOAD COMB 24 F : 1.00DL+1.40LL+0.84WF

1 1.0 2 1.4 5 0.84

LOAD COMB 25 F : 1.00DL+0.84WB

1 1.0 6 0.84

LOAD COMB 26 F : 1.00DL+1.40LL+0.84WB

1 1.0 2 1.4 6 0.84

LOAD COMB 27 F : 1.20DL+0.98LL

1 1.2 2 0.98

LOAD COMB 28 F : 1.20DL+0.98LL+0.84WL

1 1.2 2 0.98 3 0.84

LOAD COMB 29 F : 1.20DL+0.98LL+0.84WR

1 1.2 2 0.98 4 0.84

LOAD COMB 30 F : 1.20DL+0.98LL+0.84WF

1 1.2 2 0.98 5 0.84

LOAD COMB 31 F : 1.20DL+0.98LL+0.84WB

1 1.2 2 0.98 6 0.84

LOAD COMB 32 F : 1.00DL+0.98LL

1 1.0 2 0.98

LOAD COMB 33 F : 1.00DL+0.98LL+0.84WL

1 1.0 2 0.98 3 0.84

LOAD COMB 34 F : 1.00DL+0.98LL+0.84WR

1 1.0 2 0.98 4 0.84

LOAD COMB 35 F : 1.00DL+0.98LL+0.84WF

1 1.0 2 0.98 5 0.84

LOAD COMB 36 F : 1.00DL+0.98LL+0.84WB

1 1.0 2 0.98 6 0.84

LOAD COMB 37 F : 1.20DL+1.40WL

1 1.2 3 1.4

LOAD COMB 38 F : 1.20DL+0.98LL+1.40WL

1 1.2 2 0.98 3 1.4

LOAD COMB 39 F : 1.20DL+1.40WR

1 1.2 4 1.4

LOAD COMB 40 F : 1.20DL+0.98LL+1.40WR

1 1.2 2 0.98 4 1.4

LOAD COMB 41 F : 1.20DL+1.40WF

1 1.2 5 1.4

LOAD COMB 42 F : 1.20DL+0.98LL+1.40WF

1 1.2 2 0.98 5 1.4

LOAD COMB 43 F : 1.20DL+1.40WB

1 1.2 6 1.4

LOAD COMB 44 F : 1.20DL+0.98LL+1.40WB

1 1.2 2 0.98 6 1.4

LOAD COMB 45 F : 1.00DL+1.40WL

1 1.0 3 1.4

LOAD COMB 46 F : 1.00DL+0.98LL+1.40WL

1 1.0 2 0.98 3 1.4

LOAD COMB 47 F : 1.00DL+1.40WR

1 1.0 4 1.4

LOAD COMB 48 F : 1.00DL+0.98LL+1.40WR

1 1.0 2 0.98 4 1.4

LOAD COMB 49 F : 1.00DL+1.40WF

1 1.0 5 1.4

LOAD COMB 50 F : 1.00DL+0.98LL+1.40WF

1 1.0 2 0.98 5 1.4

LOAD COMB 51 F : 1.00DL+1.40WB

1 1.0 6 1.4

LOAD COMB 52 F : 1.00DL+0.98LL+1.40WB

1 1.0 2 0.98 6 1.4

LOAD COMB 53 F : 1.35DL

1 1.35

LOAD COMB 54 F : 1.35DL+0.98LL

1 1.35 2 0.98

LOAD COMB 55 F : 1.35DL+0.84WL

1 1.35 3 0.84

LOAD COMB 56 F : 1.35DL+0.98LL+0.84WL

1 1.35 2 0.98 3 0.84

LOAD COMB 57 F : 1.35DL+0.84WR

1 1.35 4 0.84

LOAD COMB 58 F : 1.35DL+0.98LL+0.84WR

1 1.35 2 0.98 4 0.84

LOAD COMB 59 F : 1.35DL+0.84WF

1 1.35 5 0.84

LOAD COMB 60 F : 1.35DL+0.98LL+0.84WF

1 1.35 2 0.98 5 0.84

LOAD COMB 61 F : 1.35DL+0.84WB

1 1.35 6 0.84

LOAD COMB 62 F : 1.35DL+0.98LL+0.84WB

1 1.35 2 0.98 6 0.84

LOAD COMB 63 D : 1.00DL

1 1.0

LOAD COMB 64 D : 1.00DL+1.00LL

1 1.0 2 1.0

LOAD COMB 65 D : 1.00DL+0.60WL

1 1.0 3 0.6

LOAD COMB 66 D : 1.00DL+1.00LL+0.60WL

1 1.0 2 1.0 3 0.6

LOAD COMB 67 D : 1.00DL+0.60WR

1 1.0 4 0.6

LOAD COMB 68 D : 1.00DL+1.00LL+0.60WR

1 1.0 2 1.0 4 0.6

LOAD COMB 69 D : 1.00DL+0.60WF

1 1.0 5 0.6

LOAD COMB 70 D : 1.00DL+1.00LL+0.60WF

1 1.0 2 1.0 5 0.6

LOAD COMB 71 D : 1.00DL+0.60WB

1 1.0 6 0.6

LOAD COMB 72 D : 1.00DL+1.00LL+0.60WB

1 1.0 2 1.0 6 0.6

LOAD COMB 73 D : 1.00DL+0.70LL

1 1.0 2 0.7

LOAD COMB 74 D : 1.00DL+0.70LL+0.60WL

1 1.0 2 0.7 3 0.6

LOAD COMB 75 D : 1.00DL+0.70LL+0.60WR

1 1.0 2 0.7 4 0.6

LOAD COMB 76 D : 1.00DL+0.70LL+0.60WF

1 1.0 2 0.7 5 0.6

LOAD COMB 77 D : 1.00DL+0.70LL+0.60WB

1 1.0 2 0.7 6 0.6

LOAD COMB 78 D : 1.00DL+1.00WL

1 1.0 3 1.0

LOAD COMB 79 D : 1.00DL+0.70LL+1.00WL

1 1.0 2 0.7 3 1.0

LOAD COMB 80 D : 1.00DL+1.00WR

1 1.0 4 1.0

LOAD COMB 81 D : 1.00DL+0.70LL+1.00WR

1 1.0 2 0.7 4 1.0

LOAD COMB 82 D : 1.00DL+1.00WF

1 1.0 5 1.0

LOAD COMB 83 D : 1.00DL+0.70LL+1.00WF

1 1.0 2 0.7 5 1.0

LOAD COMB 84 D : 1.00DL+1.00WB

1 1.0 6 1.0

LOAD COMB 85 D : 1.00DL+0.70LL+1.00WB

1 1.0 2 0.7 6 1.0

PERFORM ANALYSIS

FINISHChinese steel design parameters (.gsp file):

[version=2207]

*{ The below data is for code check general information, please do not modify it.

[CodeCheck]

SeismicGrade=None

BeamBendingStrength=1

BeamShearStrength=1

BeamEquivalentStress=1

BeamOverallStability=1

BeamSlendernessWeb=1

BeamSlendernessFlange=1

TrussStrength=1

TrussStability=1

TrussShearStrength=1

ColumnStrength=1

ColumnStabilityMzMy=1

ColumnStabilityMyMz=1

PressedTrussSlenderness=1

TensionTrussSlenderness=1

ColumnSlendernessFlange=1

ColumnSlendernessWeb=1

BeamDeflection=1

SelectAll=0

GroupOptimize=0

FastOptimize=0

Iteration=0

SecondaryMembers=

SectCollectionOrder=0

[CheckOptionAngle]

PrimaryAxis=60.000000

SecondaryAxis=60.000000

ExtendLine=10.000000

*{ The above data is for code check general information, please do not modify it.

[GROUP=1]

Name(Parameter Name)=MAINBEAM

Type(Member Type)=1

Principle(Principle Rules)=0

SteelNo()=Q235

SectionSlendernessRatioGrade(Section Slenderness Ratio Grade)=3

Fatigue(Fatigue Calculation)=0

Optimization(Perform optimized design)=0

MaxFailure(Failure Ratio)=1

MinTooSafe(Safety Ratio)=0.3

CheckLoadCase(Force Loads Case No.)=ALL

CheckDispLoadCase(Displacement Loads Case No.)=63 To 85

BeamBendingStrength()=1

BeamShearStrength()=1

BeamEquivalentStress()=1

BeamOverallStability()=1

BeamSlendernessFlange(b/t on beam)=1

BeamSlendernessWeb(h0/tw on beam)=1

TrussStrength(Axial Force Strength)=1

SecondaryMoment(Secondary Moment of Truss)=0

TrussStability(Solid-web Axial Compression Stability)=1

TrussShearStrength(Axial Shear Strength)=1

PressedTrussSlenderness(Pressed Member Slenderness)=1

TensionTrussSlenderness(Tension Member Slenderness)=1

ColumnStrength(Column Member Strength)=1

ColumnStabilityMzMy(Column Stability In-plane)=1

ColumnStabilityMyMz(Column Stability Out-plane)=1

ColumnSlendernessFlange(b/t on column)=1

ColumnSlendernessWeb(h0/tw on column)=1

CheckItemAPPENDIX_B11(Beam Deflection)=1

UseAntiSeismic(Use Seismic Adjusting Factor)=0

GamaReStr(Seismic Adjusting Factor of Load-bearing Capacity for Strength)=0

GamaReSta(Seismic Adjusting Factor of Load-bearing Capacity for Stability)=0

SLevel(Grade of Seismic Resistance)=0

lmdc(Slenderness Limit of Compression Member)=0

lmdt(Slenderness Limit of Tension Member)=0

Lmd831(Slenderness of Seismic Column)=0

Lmd841(Slenderness of Seismic Brace)=0

Lmd9213(Slenderness of Seismic Single-story Plant)=0

LmdH28(Slenderness of Seismic Multi-story Plant)=0

rz(Plastic Development Factor in Major Axis)=0

ry(Plastic Development Factor in Minor Axis)=0

gamaSharp(Plastic Development Factor of sharp side)=0

betamz(the equivalent moment factor in Major Axis plane)=0

betamy(the equivalent moment factor in Minor Axis plane)=0

betatz(the equivalent moment factor out Major Axis plane)=0

betaty(the equivalent moment factor out Minor Axis plane)=0

HasHorLoadZ(Has Horizontal Load in Z-Axis)=0

HasHorLoadY(Has Horizontal Load in Y-Axis)=0

DFF(Deflection Limit of Beam)=400

DJ1(Start Node Number in Major Axis)=0

DJ2(End Node Number in Major Axis)=0

Horizontal(Check for Deflection in Minor Axis)=0

Cantilever(Cantilever Member)=0

fabz(Overall Stability Factor in Major Axis of Bending Member)=0

faby(Overall Stability Factor in Minor Axis of Bending Member)=0

StressFeature(Select the Stress Feature to calulate stability factor of beam)=1

faz(Overall Stability Factor in Major Axis of Axial Compression Member=0

fay(Overall Stability Factor in Minor Axis of Axial Compression Member)=0

lz(Unbraced Length in Major Axis)=0

ly(Unbraced Length in Minor Axis)=0

miuz(Effective Length Factor for Column in Major Axis)=0

miuy(Effective Length Factor for Column in Minor Axis)=0

Lateral(Member in Frame Without Sidesway or not)=0

APZ(Gyration Radius Calculation as Z-Axis Parallel Leg)=0

rFlange(Limit Ratio of Width to Thickness for Flange)=0

rWeb(Limit Ratio of High to Thickness for Web)=0

BucklingStrength(Axis forced member bulking strength)=0

ZSectType(Section Type in Z-Axis)=0

YSectType(Section Type in Y-Axis)=0

HSectWebInTrussPlane(Web of H in Truss Plane)=0

rAn(Net Factor of Section Area)=1

rWnz(Net Factor of Resistance Moment in Z-Axis)=1

rWny(Net Factor of Resistance Moment in Y-Axis)=1

CapReduce(Seismic Reduction Factor of Load-bearing Capacity for Brace)=1

AngleReduce(Angle Strength Reduce)=0

LAglConSta(Connect Type of unequal single angle)=0

LAngleStrength(Reduction Factor of Angle Strength)=0

LAngleStability(Reduction Factor of Angle Stability)=0

rTrussSectReduce(Effective Factor of Axial Force Section)=1

Members(Member Number)=40