EX. US-18 Stress Calculation for Plate Elements

This is an example which demonstrates the calculation of principal stresses on a finite element.

This problem is installed with the program by default to C:\Users\Public\Public Documents\STAAD.Pro CONNECT Edition\Samples\Sample Models\US\US-18 Stress Calculation for Plate Elements.STD when you install the program.

Where:

- L = 1 ft

Fixed Supports at Joints 1, 2, 3, 4, 5, 9, 13

Load intensity = 1 psi (pound/in2) in negative global Y direction

Actual input is shown in bold lettering followed by explanation.

STAAD SPACE SAMPLE CALCULATION FOR

* ELEMENT STRESSES

Every input has to start with the term STAAD. The word SPACE signifies that the structure is a space frame (3-D structure).

UNIT KIP FEET

Defines the input units for the data that follows.

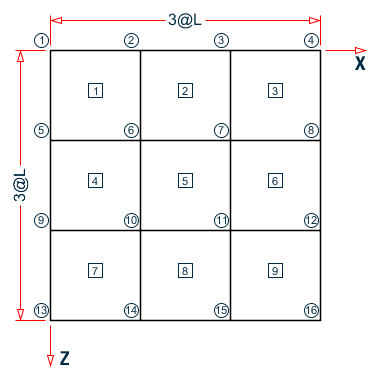

JOINT COORDINATES

1 0 0 0 4 3 0 0

REPEAT 3 0 0 1

Joint number followed by X, Y and Z coordinates are provided above. The REPEAT command is used to generate coordinates of joints 5 to 16 based on the pattern of joints 1 to 4.

ELEMENT INCIDENCE

1 1 5 6 2 TO 3

REPEAT 2 3 4

Element connectivities of elements 1 to 3 are defined first, based on which, the connectivities of elements 4 to 9 are generated.

UNIT INCH

ELEMENT PROPERTIES

1 TO 9 THICK 1.0

Elements 1 to 9 have a thickness of 1.0 in.

DEFINE MATERIAL START

ISOTROPIC CONCRETE

E 3150

POISSON 0.17

DENSITY 8.7e-005

ALPHA 5e-006

DAMP 0.05

G 1346.15

TYPE CONCRETE

STRENGTH FCU 4

END DEFINE MATERIAL

CONSTANTS

MATERIAL CONCRETE ALL

The DEFINE MATERIAL command is used to specify material properties and the CONSTANT is used to assign the material to all members.

SUPPORT

1 TO 4 5 9 13 FIXED

Fixed support conditions exist at the above mentioned joints.

UNIT POUND

LOAD 1

ELEMENT LOAD

1 TO 9 PRESSURE -1.0

A uniform pressure of 1 pound/sq. in is applied on all the elements. In the absence of an explicit direction specification, the load is assumed to act along the local Z axis. The negative value indicates that the load acts opposite to the positive direction of the local Z.

PERFORM ANALYSIS

The above command instructs the program to proceed with the analysis.

PRINT SUPPORT REACTION

The above command is self-explanatory.

PRINT ELEMENT STRESSES LIST 4

Element stresses at the centroid of the element are printed using the above command. The output includes membrane stresses, shear stresses, bending moments per unit width and principal stresses.

FINISH

The STAAD run is terminated.

Calculation of principal stresses for element 4

Calculations are presented for the top surface only.

SX = 0.0 lb/in2

SY = 0.0 lb/in2

SXY = 0.0 lb/in2

MX = 16.90 lb·in/in

MY = 85.81 lb·in/in

MXY = 36.43 lb·in/in

S = 1/6t2 = 1/6·12 = 0.1667 in3 (Section Modulus)

σx = SX + MX/S = 0.0 + 16.90/0.1667 = 101.38 psi

σy = SY + MY/S = 0.0 + 85.81/0.1667 = 514.75 psi

τxy = SXY + MXY/S = 0.0 + 36.43/0.1667 = 218.54 psi

SMax = (σx + σy)/2 + TMax = (101.38 + 514.75)/2 + 300.80 = 608.87 psi

SMin = (σx + σy)/2 - TMax = (101.38 + 514.75)/2 - 300.80 = 7.27 psi

Input File

STAAD SPACE SAMPLE CALCULATION FOR

* ELEMENT STRESSES

UNIT KIP FEET

JOINT COORDINATES

1 0 0 0 4 3 0 0

REPEAT 3 0 0 1

ELEMENT INCIDENCE

1 1 5 6 2 TO 3

REPEAT 2 3 4

UNIT INCH

ELEMENT PROPERTIES

1 TO 9 THICK 1.0

DEFINE MATERIAL START

ISOTROPIC CONCRETE

E 3150

POISSON 0.17

DENSITY 8.7e-005

ALPHA 5e-006

DAMP 0.05

G 1346.15

TYPE CONCRETE

STRENGTH FCU 4

END DEFINE MATERIAL

CONSTANTS

MATERIAL CONCRETE ALL

SUPPORT

1 TO 4 5 9 13 FIXED

UNIT POUND

LOAD 1

ELEMENT LOAD

1 TO 9 PRESSURE -1.0

PERFORM ANALYSIS

PRINT SUPPORT REACTION

PRINT ELEMENT STRESSES LIST 4

FINISH

STAAD Output File

PAGE NO. 1 **************************************************** * * * STAAD.Pro CONNECT Edition * * Version 22.07.00.** * * Proprietary Program of * * Bentley Systems, Inc. * * Date= APR 19, 2021 * * Time= 17:28: 1 * * * * Licensed to: Bentley Systems Inc * **************************************************** 1. STAAD SPACE SAMPLE CALCULATION FOR INPUT FILE: US-18 Stress Calculation for Plate Elements.STD 2. * ELEMENT STRESSES 3. UNIT KIP FEET 4. JOINT COORDINATES 5. 1 0 0 0 4 3 0 0 6. REPEAT 3 0 0 1 7. ELEMENT INCIDENCE 8. 1 1 5 6 2 TO 3 9. REPEAT 2 3 4 10. UNIT INCH 11. ELEMENT PROPERTIES 12. 1 TO 9 THICK 1.0 13. DEFINE MATERIAL START 14. ISOTROPIC CONCRETE 15. E 3150 16. POISSON 0.17 17. DENSITY 8.7E-005 18. ALPHA 5E-006 19. DAMP 0.05 20. G 1346.15 21. TYPE CONCRETE 22. STRENGTH FCU 4 23. END DEFINE MATERIAL 24. CONSTANTS 25. MATERIAL CONCRETE ALL 26. SUPPORT 27. 1 TO 4 5 9 13 FIXED 28. UNIT POUND 29. LOAD 1 30. ELEMENT LOAD 31. 1 TO 9 PRESSURE -1.0 32. PERFORM ANALYSIS SAMPLE CALCULATION FOR -- PAGE NO. 2 * ELEMENT STRESSES P R O B L E M S T A T I S T I C S ----------------------------------- NUMBER OF JOINTS 16 NUMBER OF MEMBERS 0 NUMBER OF PLATES 9 NUMBER OF SOLIDS 0 NUMBER OF SURFACES 0 NUMBER OF SUPPORTS 7 Using 64-bit analysis engine. SOLVER USED IS THE IN-CORE ADVANCED MATH SOLVER TOTAL PRIMARY LOAD CASES = 1, TOTAL DEGREES OF FREEDOM = 54 TOTAL LOAD COMBINATION CASES = 0 SO FAR. 33. PRINT SUPPORT REACTION SUPPORT REACTION SAMPLE CALCULATION FOR -- PAGE NO. 3 * ELEMENT STRESSES SUPPORT REACTIONS -UNIT POUN INCH STRUCTURE TYPE = SPACE ----------------- JOINT LOAD FORCE-X FORCE-Y FORCE-Z MOM-X MOM-Y MOM Z 1 1 0.00 -9.76 0.00 -12.51 0.00 12.51 2 1 0.00 70.14 0.00 -853.81 0.00 -16.81 3 1 0.00 301.41 0.00 -2821.43 0.00 95.50 4 1 0.00 281.33 0.00 -2127.22 0.00 -769.10 5 1 0.00 70.14 0.00 16.81 0.00 853.81 9 1 0.00 301.41 0.00 -95.50 0.00 2821.43 13 1 0.00 281.33 0.00 769.10 0.00 2127.22 ************** END OF LATEST ANALYSIS RESULT ************** 34. PRINT ELEMENT STRESSES LIST 4 ELEMENT STRESSES LIST 4 SAMPLE CALCULATION FOR -- PAGE NO. 4 * ELEMENT STRESSES ELEMENT STRESSES FORCE,LENGTH UNITS= POUN INCH ---------------- STRESS = FORCE/UNIT WIDTH/THICK, MOMENT = FORCE-LENGTH/UNIT WIDTH ELEMENT LOAD SQX SQY MX MY MXY VONT VONB SX SY SXY TRESCAT TRESCAB 4 1 10.43 -9.94 16.90 85.81 36.43 605.39 605.39 0.00 0.00 0.00 608.99 608.99 TOP : SMAX= 608.99 SMIN= 7.25 TMAX= 300.87 ANGLE= 66.7 BOTT: SMAX= -7.25 SMIN= -608.99 TMAX= 300.87 ANGLE=-23.3 **** MAXIMUM STRESSES AMONG SELECTED PLATES AND CASES **** MAXIMUM MINIMUM MAXIMUM MAXIMUM MAXIMUM PRINCIPAL PRINCIPAL SHEAR VONMISES TRESCA STRESS STRESS STRESS STRESS STRESS 6.089873E+02 -6.089873E+02 3.008683E+02 6.053945E+02 6.089873E+02 PLATE NO. 4 4 4 4 4 CASE NO. 1 1 1 1 1 ********************END OF ELEMENT FORCES******************** 35. FINISH SAMPLE CALCULATION FOR -- PAGE NO. 5 * ELEMENT STRESSES *********** END OF THE STAAD.Pro RUN *********** **** DATE= APR 19,2021 TIME= 17:28: 1 **** ************************************************************ * For technical assistance on STAAD.Pro, please visit * * http://www.bentley.com/en/support/ * * * * Details about additional assistance from * * Bentley and Partners can be found at program menu * * Help->Technical Support * * * * Copyright (c) Bentley Systems, Inc. * * http://www.bentley.com * ************************************************************