Checking Connectivity

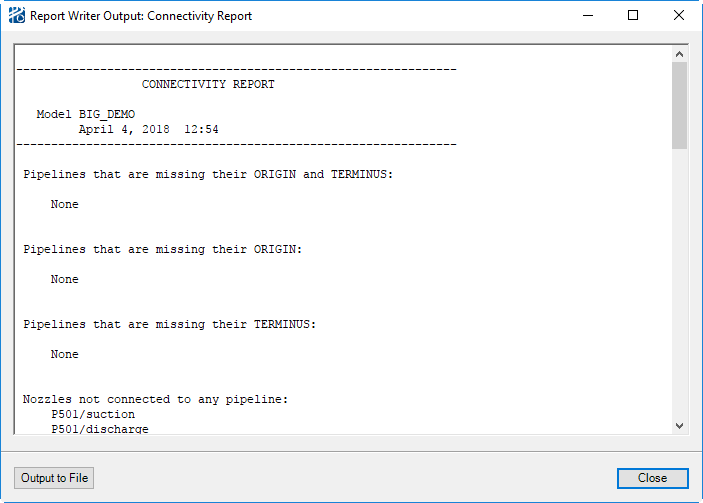

To verify the connectivity, select the menu in the PlantWise window or the PlantWise > Process menu in the MicroStation command window. This produces a connectivity report in a PlantWise Text Display window.

The following checks are made:

| Check | Description |

|---|---|

| Are there pipelines without an origin and/or a terminus? | This is a crucial item for routing. A pipeline cannot be routed without one (and only one) origin and one (and only one) terminus. |

| Are there pipelines with multiple Origins and/or Termini? | PlantWise does not allow this situation to occur when manually entering connectivity. However, if connectivity information has been imported electronically this can occur and needs to be corrected before the lines involved can be routed. |

| Are there nozzles or boundary components that have no connected pipelines? | This item is provided for information only. The AutoRouter does not require all defined nozzles and boundaries to be connected. |

| Are there nozzles or boundary components that are connected to more than one pipeline? | This is only a possibility if connectivity information has been electronically imported into PlantWise. The AutoRouter can not route these lines before this error is corrected. |

| Are there any piping networks that are unroutable? | A network is routable if and

only if there is a legal sequence for routing all the pipelines in the network.

Each pipeline must have an origin and a terminus at a location that can be

determined at some point in the routing process. Origins and termini at

equipment nozzles or at boundary components are always locatable, hence

pipelines between them are routable. A tee along a routable pipeline is

locatable, hence a pipeline originating or terminating at such a tee is

routable. Any other situations are not routable.

For example, two pipelines connecting end-to-end – A’s terminus is B and B’s origin is A – is not routable because A’s terminus (and B’s origin) are not locatable. Additionally, any pipelines connecting into such a pipeline are not routable. |

| Have there been any changes to inline sequences as a result of connectivity changes? | Some connectivity changes can affect the set of inline components in a pipeline. For example, changing the origin of pipeline B from pipeline A to boundary C actually affects the inline component set for pipeline A: when pipeline B originated at pipeline A, pipeline A contained a tee to pipeline B in its set of inline components. Changing B’s origin hence affects A’s set of inline components. In this situation, the Plant Builder reverts any user-defined inline sequencing to a default state and notifies you of this change in the connectivity check. |

| Are there any branch lines referenced in a pipeline’s sequences list that do not contain the pipeline as the branch’s origin or terminus? | Data in a process model connectivity file may not necessarily be consistent between pipelines’ sequences list and referenced pipelines’ origins and termini. |

| Are there any pipelines with an inconsistency in diameter? | It is possible to connect differently sized pipes to nozzles. If this happens, PlantWise can route the pipe but it will have an exceptions. There are generally three possibilities for this error: the pipeline has been defined with the wrong diameter, the nozzle has been defined with the wrong diameter, or a reducer was not added to the pipeline’s inline sequence. The decision for how to correct the inconsistency is left to you. |