Export to FabShop HVAC Fabrication

Used to export FabShop compatible

component data for automated fabrication to fabrication software.

Used to export FabShop compatible

component data for automated fabrication to fabrication software.

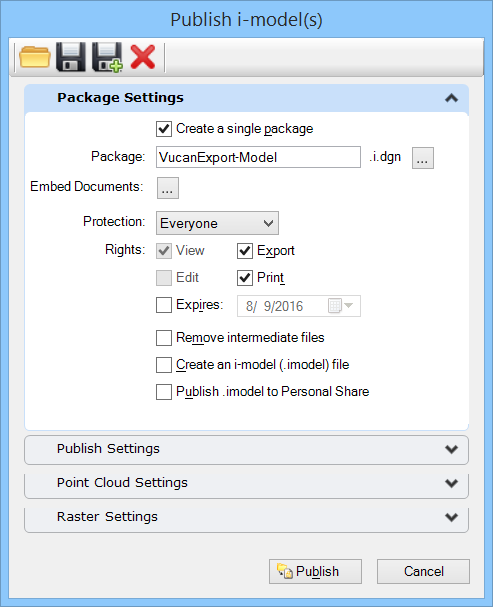

The export maps the component data embedded in i-model to all properties and parameters set for automated duct fabrication. Component mapping achieves precise results of Export Component data supporting i-model interoperability. The component data ranges from catalog types, properties and standard options and their order corresponds to FabShop pattern library which is securely embedded in the i-model.

In FabShop software, you can set up a project in a given unit system and create a job. The job information of a fitting standards for a given metal, liner, pressure and associated label and options is defined. Pattern mapping for the most common fittings is appended automatically to the Bentley model and i-dgn created from the design. The i-model file is then imported in the job, which can drive the most commonly industry used cutting tables. The import commands makes use of the mapped data and populates the component details in a tabulated format. Once the job is processed it generates graphical patterns on a drawing sheet for review. Once in FabShop the fitting patterns are laid out to minimize material waste and allow for lock and seam allowances. Specifications can be set based on pressure gauge and labels are created to assemble and identify the fittings.

The component data includes catalog types, properties and standard options and their order correspond to FabShop pattern library is imported back to FabShop data using external utility such as Trimble®i-ModelExportConversion utility, (formerly, iModel2Vulcan).