| Arrange Type

|

Set the layout type for the hole fields;

- Rectangular –

enables settings for rectangular type layout.

- Polar – enables

settings for radial type layout.

The drilling pattern will be applied according to

the members forming the pairs and it will not be possible to have the pattern

according to the supporting member. The entered pattern will be repeated on

every pair.

|

| Drill Type

|

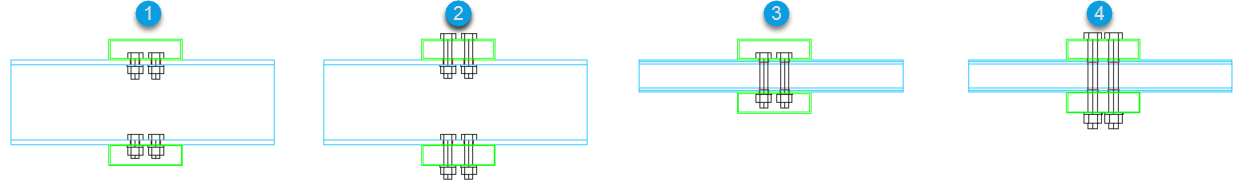

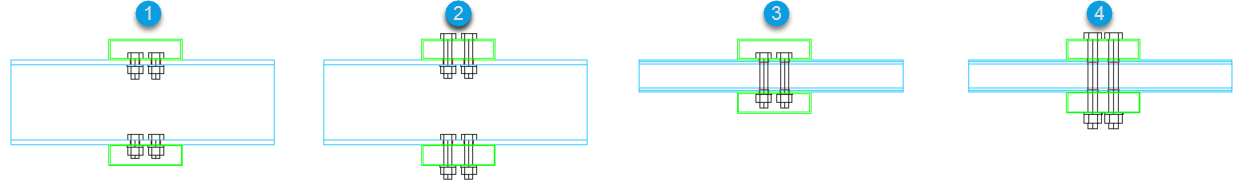

Sets one of the four drilling cases, that determines

which flange to other flange the shape be drilled and bolted.

All the shapes in the below Figure are hollow and

the support members are indicated in blue and located between the connecting

members.

Hollow

support in center

- Case

1 – The bolts go from the top flange of

the supporting member to the bottom flange of the top connecting member and

from the bottom flange of the supporting member to the top flange of the bottom

connecting member.

- Case

2 – The bolts go from the top flange of

the supporting member to the top flange of the top connecting member and from

the bottom flange of the supporting member to the bottom flange of the bottom

connecting member.

- Case

3 – The bolts go from the bottom flange

of the top connecting member to the top flange of the bottom connecting member.

- Case

4 – The bolts go from the top flange of

the top connecting member to the bottom flange of the bottom connecting member.

|

| Longitudinal Spacing

|

Enabled for Rectangular type layout pattern.

- Number – Sets

the number of bolts to be placed on the longitudinal direction. It's the X

orientation for the polyplate member, and Z orientation for shape member

according to which the pattern is set.

- First

Distance – Sets the distance from the starting edge to the center

of the first bolt.

- Subsequent

Distance – Sets the subsequent distance between longitudinal bolts.

Note: Distances

can be entered as direct values or as multiples of the bolt diameter. To enter

a multiplier of a bolt diameter as a distance, an *

precedes the multiplier of the bolt diameter. If a bolt has a diameter of 1

inch, then entering a distance of

*2 will result in a

2 inch distance.

|

| Transverse Spacing

|

Enabled for Rectangular type layout pattern.

- Number – Sets

the number of bolts to be placed on the transversal direction. It's the Y

orientation for the polyplate member, and the other direction for shape member

according to which the pattern is set.

- First

Distance – Sets the distance from the starting edge to the center

of the first bolt.

- Subsequent

Distance – Sets the subsequent distance between transversal bolts.

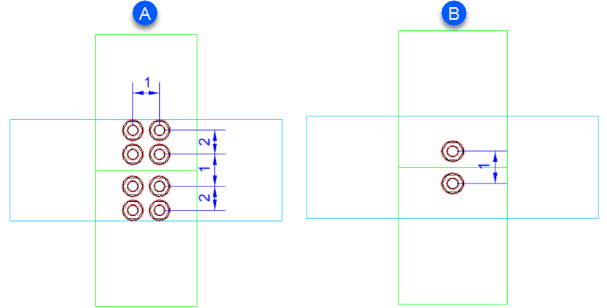

Examples: If the number of bolts in a

direction is

even, the user enters a first distance

between the bolts (1) and a subsequent distance between the bolts (2). If there

are only two bolts in a direction, the subsequent distance (2) is ignored. See

Figure 1 and Figure 2.

|

| Polar (radial)

|

Enabled for Polar type layout pattern.

- Count – Sets

the number of holes in the radial hole field.

- Radius – Sets

the radius of the radial pattern.

- Starting

Angle – Defines the starting angle of the distribution of the

radial hole field in relation to the insert axis.

- Included

Angle – Indicates the angle for which the radial holes will be

distributed, ranges between 0° and 360°.

Note: The radial

drilling pattern is not available in paired mode

|

| Bolts

|

- Bolt

Type – Sets the bolt style from the drop-down list.

- Diameter – Sets

the hole diameter of the selected bolt from the drop-down list of bolt diameter

table.

- Workloose –

Sets the clearance between bolt and hole diameter.

- Additional

Length – Sets an additional length to the bolts extension outside

the nut.

- Slot

Length – Sets the slotted hole distance along longitudinal

direction.

- Slots

On – Indicates the member or pair on which slots will be applied.

- Turn – When

checked, the bolt direction is inverted. Available when not welded.

Stagger - Click to increment

the stagger bolts stages (0-4). Applicable to pair mode selection.

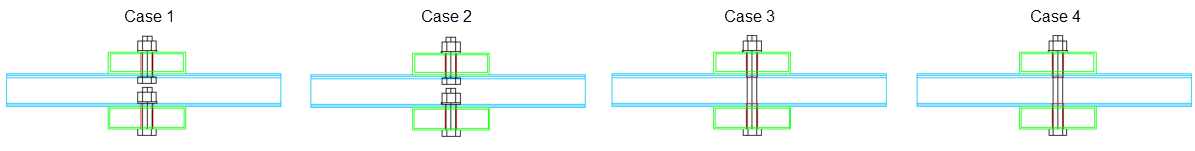

Staggered Bolting

When using a rectangular drilling pattern only, it

is possible to have staggered bolts. There are 4 cases of staggered bolting.

Bolts can be staggered in the longitudinal direction of the supporting shapes.

Staggered bolts are also supported for polyplates. The bolts will be staggered

in the X direction of the polyplate.

- The top 2 images have their

odd numbered rows of bolts

staggered and the bottom 2 images have their

even numbered rows of bolts

staggered.

- In the 2 images to the left, the bolts are

staggered to the

right and in the 2 images to the

right the bolts are staggered to the

left.

The bolts are staggered by half the first distance

between the bolts if there are only 2 or 3 bolts in the longitudinal direction

for member mode or 1 bolt in the longitudinal direction for paired mode. If

there are more than 3 bolts in the longitudinal direction for member mode or

more than 1 bolt for paired mode (the number of bolts is repeated on the other

side), they are staggered by half the subsequent distance between bolts.

|

| Pattern with respect to

|

Indicates the member according to which the pattern

is applied. In case of paired mode, the pattern is according to the members

forming the pair. Use the

> icon to travel through valid pattern

members in the list.

|

| Pattern perpendicular to

|

Indicates the member according to whose surface the

drilling is perpendicular to. In case of paired mode, the pair to whoich a

member belongs is indicated. Use the

> icon to travel through valid

perpendicular to members in the list.

|

| Rotation Angle

|

Sets the axial rotation of the bolt.

You can decide which member will have slots applied

to it. The orientation of the slots can only turn by 90°. When in paired mode,

if a shape forming a pair has slots applied to it, the other shape will also

have slots applied to it. Slot orientation and alignment is according to the

member defining the drilling/bolting pattern.

+90º turns the slots by 90º

counterclockwise, and

-90º turns it by 90º clockwise.

|