Momentum Equation for Unsteady Flow

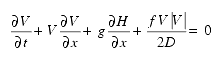

The equations of motion for a fluid can be derived from the consideration of the forces acting on a small element, or control volume, including the shear stresses generated by the fluid motion and viscosity. The three-dimensional momentum equations of a real fluid system are known as the Navier-Stokes equations. Since flow perpendicular to pipe walls is approximately zero, flow in a pipe can be considered one-dimensional, for which the continuity equation reduces to:

The last term on the left-hand side represents friction losses in the direction of flow:

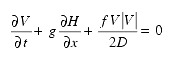

The first term on the left-hand side is the local acceleration term, while the second term represents the convective acceleration, proportional to the spatial change of velocity at a point in the fluid, which is often neglected to yield the following simplified equation:

Equations and , though rigorous and explicit, incorporate the following assumptions, which are often not strictly valid in real water systems:

- Fluid is homogeneous—water typically incorporates a small amount of dissolved and/or entrained air whose exact percentage changes along the system.

- Fluid and pipe wall are linearly elastic—in aging water pipes whose shape has become noncircular and whose integrity may be compromised by cracks (virtually every water system leaks), fluid may escape the system rather than being compressed and deformations imposed on piping may not be entirely recovered.

- Flow is one-dimensional—this assumption has been shown to be inaccurate at tees in suction lines. Minor losses result from three-dimensional vorticity.

- Pipe flows full—even in pressurized systems, air or vapor can accumulate at local high points, forcing the water to accelerate and pass underneath it. In extreme cases, this phenomenon can significantly diminish pumping efficiency (e.g., vapor lock).

- Average velocity is used—experiments show that the velocity distribution changes across a cross section during transient events, even for flow in straight pipes.

- Viscous losses similar to steady state—emerging research in transient or unsteady friction is challenging this assumption.

Nevertheless, these assumptions are essentially valid for the majority of the time in the majority of water systems. Solving these equations yields accurate numerical simulation results in most cases.